- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Pengfei

-

Dimension(L*W*H):

-

2000*2320*1730mm

-

Weight:

-

11600 KG

-

After-sales Service Provided:

-

No after-sales service

-

motor:

-

SIMENS

Quick Details

-

Application:

-

cement plant or mining

-

Capacity(t/h):

-

20-85

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Pengfei

-

Dimension(L*W*H):

-

2000*2320*1730mm

-

Weight:

-

11600 KG

-

After-sales Service Provided:

-

No after-sales service

-

motor:

-

SIMENS

1. APPLICATION

This jaw crusher is used for crushing ores or rocks in various industries, such as mining, building materials, silicate, chemical engineering, etc. the feed size of the crusher is not more than 210mm, and the compressive strength of the crushed materials does not exceed 250Mpa.

2. SPECIFICATOINS & PERFORMANCE

2.1 Dimension of feeding port(W*L) : 300*1300mm

2.2 Width of discharge port : 20-90mm

2.3 Max. feeding size : 250mm

2.4 Rotating speed of main shaft : 300r/min

2.5 Protective capacity : 20-85t/h

2.6 Motor Type : Y315M1-8

Power : 75 kW

Speed : 750r/min

2.7 Overall size(L*W*H) l: 2000*2320*1730 mm

2.8 Weight(except for motor) : 11600 kg

Notes: The productive capacity of this crusher will vary upon different properties, shapes, sizes of the materials fed into the crusher, method of feeding, working condition etc. The indicated crushing capacity is obtained by crushing the medium hardness dry rocks, and its specific weight is 1.6 metric ton per cubic meter.

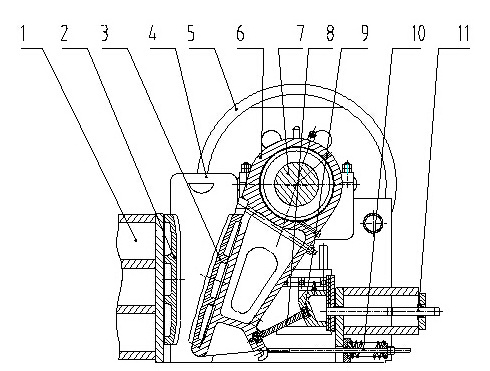

3. WORKING PRINCIPLES & CONSTRUCTION

1 frame 2 fixed jaw plate 3 movable jaw plate 4 side fender 5 fly, the groove wheel 6 jaw 7 eccentric shaft 8 cubits plate 9 adjusting seat 10 tension spring device 11 adjusting bolt (see Figure 1)

4. SAFETY OPERATING RULES

6.1 The operators may operate the crusher after being trained of the safety rules.

6.2 Observing the inside of the crusher from the top of the crushing chamber during the operation is prohibited.

6.3 No adjusting, cleaning and repairing during the operation is permitted.

6.4 Removing the materials from the feed opening or the crushing chamber directly by hand is strictly not permitted during the operation.

6.5 The electrical equipment of the crusher shall be properly grounded, and the wires inserted into the insulated snake skin hose.