- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Vary by capacities of ethanol distillery

-

Processing Types:

-

maize,molasses,sugarcane,cassava

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Item:

-

Alcohol distillation Column/ Ethanol Distillation Column

-

Usage:

-

Alcohol Distiller

-

Material:

-

SUS304/SUS316/red Copper

-

Name:

-

Industrial Alcohol Distillation Equipment

-

Keyword:

-

ethanol distillery

-

Control System:

-

PLC main parts Siemens

Quick Details

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

220v/380v/440v ,adjustable

-

Weight:

-

65000 KG

-

Dimension(L*W*H):

-

Vary by capacities of ethanol distillery

-

Processing Types:

-

maize,molasses,sugarcane,cassava

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Item:

-

Alcohol distillation Column/ Ethanol Distillation Column

-

Usage:

-

Alcohol Distiller

-

Material:

-

SUS304/SUS316/red Copper

-

Name:

-

Industrial Alcohol Distillation Equipment

-

Keyword:

-

ethanol distillery

-

Control System:

-

PLC main parts Siemens

Alcohol distillation tower / Ethanol Distillation Column

E xperienced manufacturer with lifetime service

1.

It is

a turn-key whole set equipment

,

simple equipment, less workers, less area, less cost.

2. We can design, manufacture, install and

debug

the

project

which can produce

500L-1000000L alcohol (ethanol)

/methanol

per day.

3. We can use corn /maize , wheat, cassava, molasses, rice, potato, date, beetroot,sugar cane ect which contains starch or sugar material to produce alcohol /ethanol /methanol .

4. We can do the turn key system or section part of the alcohol/ ethanol plant .

5. We can improve and rebuild old alcohol(ethanol) factory .

6. We can provide energy saving advice and instruction of civil works.

You can choose single rectification distillation tower to save money, also can choose 2-6 distillation columns or more to get superfine quality alcohol(ethanol) or even higher ones .

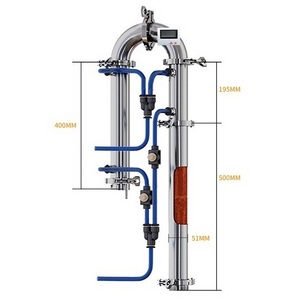

Alcohol distillation tower is usually made of skirt seat, tower body, seal head, steam intake pipe mouth, steam outlet pipe mouth, material inlet pipe mouth, reflux pipe mouth, mouths to test temperature and pressure ect. Some towers have several mouths for picking out finished product and impurity. Multilayer float valves are installed inside the towers, the contacting part of steam and liquid- float valves are uniformly set on each tower tray. On each tray steam and liquid contact countercurrent progressively. Float valve in the tray can be up and down. The float valve is opened by the impulse of rise steam. The open stage is decided by the steam speed. The rising steam jacks the valve plate through the valve hole, the air is sprayed to all sides at horizontal direction, medium exchange is completed when steam and liquid contact. When the steam speed is low, the valve automatically falls down because of gravity to reduce the leakage, so float valve trays have the following advantages: high working efficiency, high operation flexibility, high production ability, with little foam fog in flash steam ,long contacting time for steam and liquid, and good result for mass transfer.

1: Before Service : All the process es of alcohol/fuel ethanol production line are specially designed by Technical deportment according to each customer’s requirements and we have Strict Quality Control System of all the alcohol/ fuel ethanol equipment.

2: Middle Service : Supply e ngineers and workers training during the installation and debugging of the alcohol/fuel ethanol plant. If a ny question, pls feel free to contact us for solution.

3: After Service : Supply lifetime technology consultation and advice of the alcohol/fuel ethanol production plant. If you have any problem or question about the alcohol distillery/bio ethanol plant , pls call us and E- mail us at any time, we will reply to you at the shortest time. Engineers are available to go to plant site to help customers to improve processes or technology if required.