- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

WEIER

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

20m*2m*2.5m

-

Power (kW):

-

75

-

Weight:

-

15000 KG

-

Name:

-

Single wall corrugated pipe making machine extrusion line with CE

-

Raw material:

-

pvc pp pe eva

-

Usage:

-

electric conduit

-

Keywords:

-

corrugated pipe making machine

-

After Warranty Service:

-

Engineers

-

Processing Type:

-

Exturding Machine

-

Product Type:

-

pipe

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

1000 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

WEIER

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

20m*2m*2.5m

-

Power (kW):

-

75

-

Weight:

-

15000 KG

-

Name:

-

Single wall corrugated pipe making machine extrusion line with CE

-

Raw material:

-

pvc pp pe eva

-

Usage:

-

electric conduit

-

Keywords:

-

corrugated pipe making machine

-

After Warranty Service:

-

Engineers

-

Processing Type:

-

Exturding Machine

-

Product Type:

-

pipe

Product Description

Specification

|

Pipe Line Model

|

Diameter Range(mm)

|

Extruder Model

|

Max Output(kg/h)

|

Max Machine Speed(m/min)

|

Main motor power(kw)

|

Line Length(m)

|

|

WR-16

|

Φ5-Φ16

|

SJ45

|

50

|

25

|

22

|

10

|

|

WR-50

|

Φ16-Φ50

|

SJ65

|

100

|

25

|

37

|

10

|

|

1,Used condition :

|

380V/3phase/50HZ

|

|

2,Suitable material :

|

PP, PE , PVC

|

|

3,Pipe range :

|

φ9-50mm

|

|

4, output capacity:

|

60-80kg/h

|

|

Production speed

|

20-30m/min

|

|

Extruder model

|

SJ65

|

|

Main motor power

|

22kw

|

|

Machine size

|

12m*1m*3m(length*width*height)

|

|

Machine list

|

Quantity

|

|

SJ65/30 single screw extruder with auto feeder and drying hopper

|

1 set

|

|

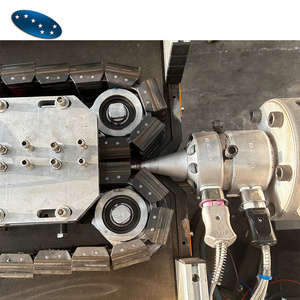

Die head

|

1 set

|

|

Mold: 72 pais of mold blocks

|

according to customer's requirements

|

|

Steel wire unwiding and inserting device

|

1 set

|

|

Forming machine: with water cooling

|

1 set

|

|

Coiling machine, double station

|

1 set

|

|

Electricity control system

|

1 set

|

|

Spare parts

|

1 set

|

Details Images

Packing & Delivery

ISO certified PC plastic hollow sheet production line extruder packing method:

1. Cover the fuselage with waterproof film first, and then fix it on the wooden tray at the exit with bolts and wires.

2. The electronic control parts and spare parts are packed in wooden cases respectively.

The auxiliary equipment is also packed in wooden cases.

4. All wooden materials have been fumigated and certified, and are exported to all parts of the world safely.

Hot Searches