- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HCX

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

4040mm*396mm*1880mm(L*W*H)

-

Weight:

-

4500 kg

-

Marketing Type:

-

Hot Product

-

Main function:

-

Die cutting, perforating, slitting

-

The method of paper loading:

-

Automatic paper loading

-

Webguide system:

-

Independent ultrasonic skew adjustment

-

Tension system:

-

Automatic tension control

-

Count way:

-

Automatic metering

-

Magnetic roller replacement mode:

-

drawer type

-

Waste discharge type:

-

scraper type

Quick Details

-

Type:

-

Die-cutting slitting machine

-

Production Capacity:

-

120 m/min

-

Max. workable width:

-

570mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HCX

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

4040mm*396mm*1880mm(L*W*H)

-

Weight:

-

4500 kg

-

Marketing Type:

-

Hot Product

-

Main function:

-

Die cutting, perforating, slitting

-

The method of paper loading:

-

Automatic paper loading

-

Webguide system:

-

Independent ultrasonic skew adjustment

-

Tension system:

-

Automatic tension control

-

Count way:

-

Automatic metering

-

Magnetic roller replacement mode:

-

drawer type

-

Waste discharge type:

-

scraper type

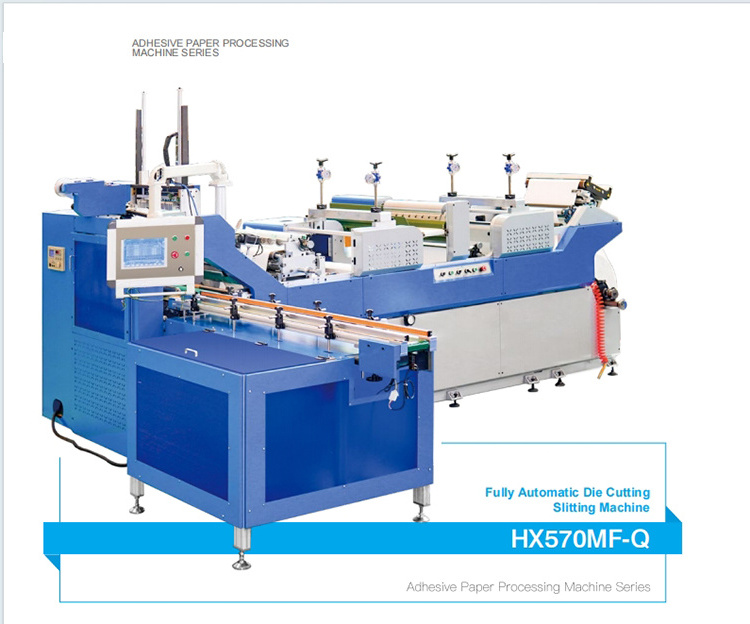

Automatic label fully rotary roller die cutting machine for sticker label

HX 570MF-Q

Fully automatic die cutting & slitting machine

Product introduction:

This machine is a new wide die cutting and slitting product developed by our company according to the needs of domestic and foreign markets. It can realize automatic paper feeding , automatic web-guide , die cutting, line pressing , slitting , independent waste discharge, rewinding, cutting, labeling, threading tube core and finished product delivery . It does not need manual participation in the whole process. It can realize the whole process automatic work cycle, with fast working speed and excellent performance, it is a new generation of ideal self-adhesive die cutting equipment.

Servo motors are used in many parts of this die cutting machine to ensure the accuracy of each step. The unique tension system and web-guide system design enable the same high quality products to be processed from the base paper with different thickness and loose and tight edges; this machine adopts frequency converter speed regulation and PLC control. The operation interface is touch screen and automatic tension device. It is easy to operate and fast to adjust. This machine has the accurate length counting function and the whole machine ’ s base paper length counting function; this machine uses high quality materials, high quality accessories, advanced technology, and imported bearings to ensure the durability of the machine.

|

T ype |

HX 570MF-Q |

|

Max.unwinding width |

570mm |

|

Min. Unwinding width |

100mm |

|

Max. Unwinding diameter |

Φ 1000mm |

|

Max. Die cutting rewinding diameter |

Φ 200mm |

|

Min. Die cutting width |

15mm |

|

Min. Die cutting rewinding diameter |

Φ 25mm |

|

Max. Diameter of die cutting rewinding paper core |

Φ 80mm |

|

Inner diameter of base paper core |

Φ 76mm |

|

Working speed |

0-120m/min |

|

Paper loading method |

electric automatic paper feeding |

|

Web-guide method |

Ultrasonic |

|

Magnetic roller pressure regulation method |

Pressure gage |

|

Waste discharge method |

Servo (shovel waste ) |

|

Die cutting station |

Dual station |

|

Installation method of magnetic roller |

Drawer type(hydraulic trolley) |

|

Main motor |

Servo |

|

Method of threading the core |

Automatic |

|

Cutting method |

Automatic |

|

Method of rolling paper |

Slotting tool |

|

Rewinding spindle |

3 pcs |

|

Blanking method |

Automatic |

|

Labeling method |

automatic |

|

Power |

3PH/380V/50Hz |

|

Compressed air |

0.8Mpa(dry and clean compressed air) |

|

Size ( L*W*H ) |

4040*3960*1880mm |