- Product Details

- {{item.text}}

Quick Details

-

Capacity:

-

100-300kg/h for fuel,300-700 for animal feed

-

Pellet size:

-

2-6mm

-

Material:

-

Alloy Steel or stainless steel

-

Spare parts:

-

mould and roller

-

Ideal moisture:

-

13-15%

Quick Details

-

Place of Origin:

-

Shandong, China

-

Name:

-

Animal feed pellet production line in feed processing machines

-

Raw material:

-

Sawdust,straw,rice husk,palm,alfafa,waste wood etc.

-

Capacity:

-

100-300kg/h for fuel,300-700 for animal feed

-

Pellet size:

-

2-6mm

-

Material:

-

Alloy Steel or stainless steel

-

Spare parts:

-

mould and roller

-

Ideal moisture:

-

13-15%

Animal feed pellet production line in feed processing machines/animal feed pallet machine

Product Application

It avoids dislocation friction between rollers and dies, so the dies' lifetime is enlarged.This is significant

difference between the similar compression formation machines.

2. It adopts screw-center adjusting pressure structure; the pressed rollers' gap is adjustable. It meets the

different materials demand and make sure the pelleting effect.The taper rollers and flat dies have the unique

advantages of enlarging the rollers, so they are can not be replaced compared with other related equipments.

3.Larger rollers with wide groove, bear more pressure and abrasion.

Main features of Farm machinery full automatic electrical motor wood pellet making machine/animal feed pellet machine for chickens,rabbits,ducks

1,Main drive adopts high accuracy gearbox;

2,Full stainless steel enlarged conditioner ensures good cooking effect;

3,Frequency conversion (Electromagnetic speed control) feeder, with overload protection device,equipped strong magnetic security device;

4,High efficiency driving, stable and low noise;

5,Main parts of the bearing and standard parts are imported.

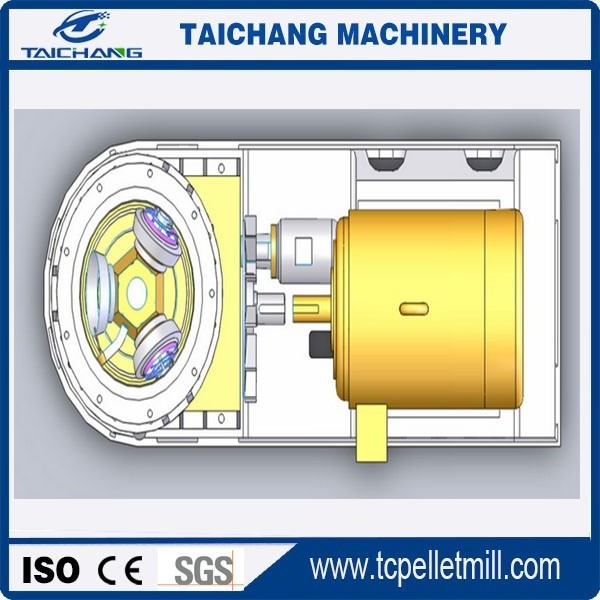

Machine Features

Name: TCZL250 Wood pellet mill

Brand: Taichang

Original: China

Remarks

:Domestic famous engines, strong driving force, low fuel consumption, high economic benefits .

Main Parts

Name:

Spare part

Brand:

Taichang

Original:

China

Remarks :

Alloy steel mould working time:800-1000H

Stainless steel mould working time:1500H

Working principle

Granulating the material into the chamber from the mold rotatingfriction wheel rotation,so that the material extruded into the mold hole,made secret into cylindrical bar,after the knife cutting at the discharge port,to form particles,get out of the granulation chamber.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate