- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

All size available

-

Particle:

-

0.6~2.0μm

-

content:

-

CO+WC

-

Hardness:

-

HRA89.5-92.0

-

Density:

-

14.0-14.8g/mm3

-

T.R.S (Mpa):

-

>3000Mpa

-

Size:

-

Customized

-

Material:

-

Cemented carbide

-

Surface:

-

Sandblasting and Passivation

-

Product name:

-

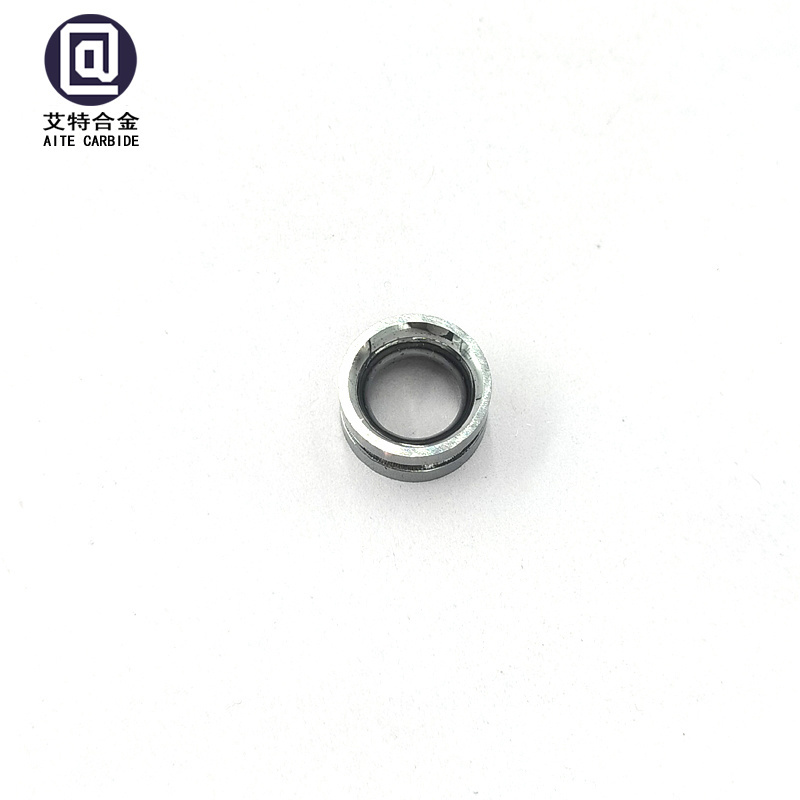

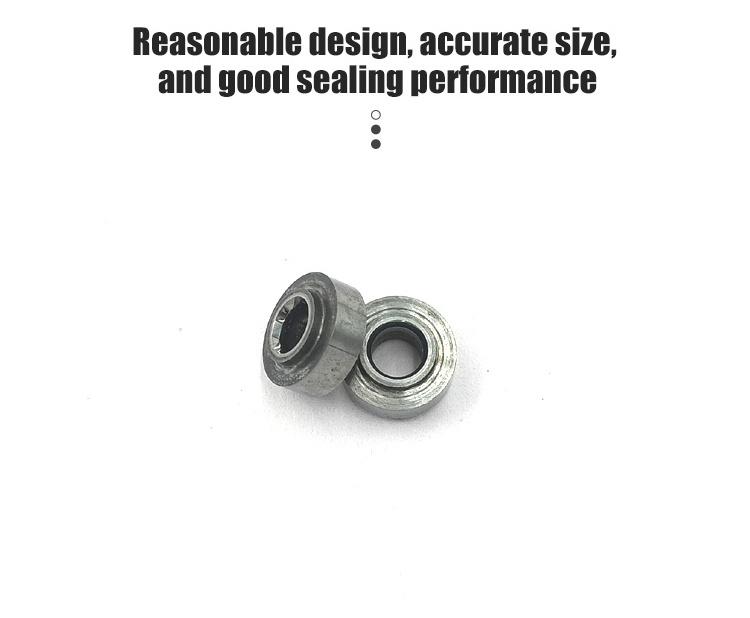

Tungsten Carbide Wear-resistant Parts

-

Advantage:

-

High Wear Resistance

Quick Details

-

Alloy Specification:

-

K10 K20 K30 YG8 YG6X YG10X YG12X YL10.2

-

Place of Origin:

-

Hunan,China

-

Brand Name:

-

AI REN TE

-

Model Number:

-

All size available

-

Particle:

-

0.6~2.0μm

-

content:

-

CO+WC

-

Hardness:

-

HRA89.5-92.0

-

Density:

-

14.0-14.8g/mm3

-

T.R.S (Mpa):

-

>3000Mpa

-

Size:

-

Customized

-

Material:

-

Cemented carbide

-

Surface:

-

Sandblasting and Passivation

-

Product name:

-

Tungsten Carbide Wear-resistant Parts

-

Advantage:

-

High Wear Resistance

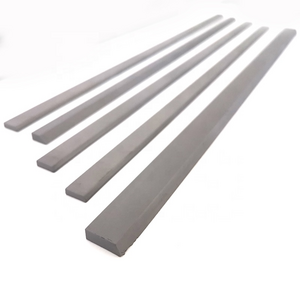

Carbide non-standard shape product introduction

1. Use 99.95% high purity raw material tungsten carbide powder.

2. Using spray drying technology, the material is protected by high-purity nitrogen under fully sealed conditions, effectively reducing the possibility of oxygen increase during the preparation of the mixture, and the purity is better, and the material is not easy to dirty.

3. Using low pressure sintering technology, excellent compactness, high wear resistance and impact resistance.

4. Tungsten carbide non-standard shaped products: non-standard carbide blade, non-standard carbide die, non-standard carbide plate, non-standard carbide wear parts and so on.

5. Size and specification: according to the customer to provide samples or drawings production.

6. Grade: K10,K20,K30,K40,YG6,YG8,YG11,YG15,YG20,YG6X,YG10X,YG8C,YL10.2,etc.

|

Grade

|

ISO code

|

Cobalt content

(%) |

Density

(g/cm3 ) |

Hardness (HRA≥)

|

T.R.S (n/mm3)

|

|

YG6

|

K10~K20

|

6

|

14.9

|

90.0

|

≥3200

|

|

YG8

|

K20~K30

|

8

|

14.8

|

89.5

|

≥3500

|

|

YG11

|

K40

|

11

|

14.4

|

88.5

|

≥3650

|

|

YG15

|

K40

|

15

|

14.0

|

87.5

|

≥3800

|

|

YG6X

|

K10

|

6

|

14.9

|

91.5

|

≥3200

|

|

YG10X

|

|

10

|

14.5

|

91.0

|

≥3650

|

|

YL10.2

|

K10

|

10

|

14.5

|

92

|

≥3850

|

Hot Searches