- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

MM series

-

Product type:

-

Mould Fabrication as design requirement or sample

-

Mould base:

-

LKM,HASCO,or Mr.Mould customed

-

Mould life:

-

According to your requirement

-

Part Material:

-

Metal

-

CNC tolerance:

-

0.001 to 0.005 mm

-

Cavity:

-

Single/Family,as request

-

Tooling machine:

-

CNC , EDM , Engraving ,Wire-Cutting

Quick Details

-

Shaping Mode:

-

Punching Mold

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Mr.Mould

-

Model Number:

-

MM series

-

Product type:

-

Mould Fabrication as design requirement or sample

-

Mould base:

-

LKM,HASCO,or Mr.Mould customed

-

Mould life:

-

According to your requirement

-

Part Material:

-

Metal

-

CNC tolerance:

-

0.001 to 0.005 mm

-

Cavity:

-

Single/Family,as request

-

Tooling machine:

-

CNC , EDM , Engraving ,Wire-Cutting

battery terminal stamping mould

What kind of information need for quotation?

1,Sample photo with size or 2D/3D design

2, Cavity quantity

3, Product material

4,Mould steel type.

5,Stamping/punching machine parameter

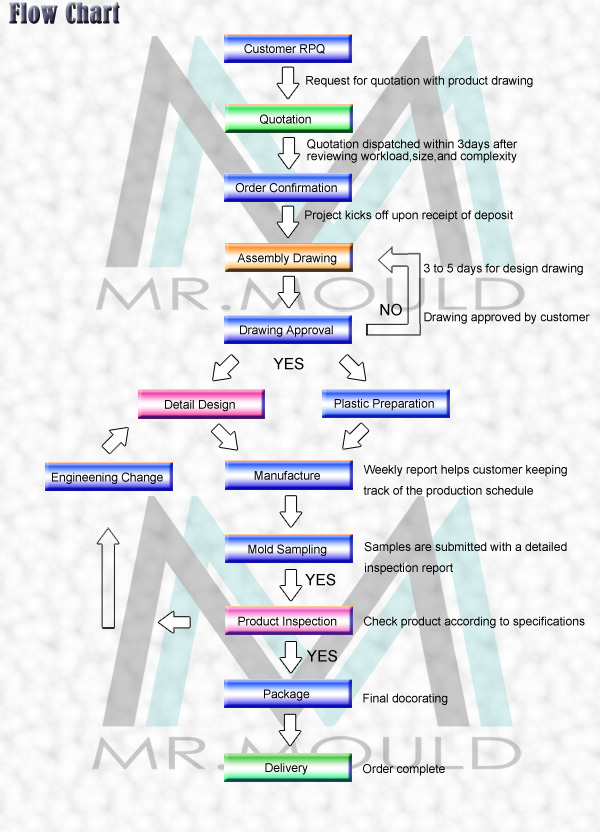

1. Trading Step:

2.Moulding & Fabrication

With advanced management concepts and complete processing equipments,we are a one-stop service company gathering research,development,desgin,manufacture,processing and technical training. So that We have rich successful experience in making all kinds of moulds according to customer's requirements .

The mould making center equiped with CNC machines for precise moulds.Equiped with advanced CAD/CAM development and design system,a high-level designing and manufacturing team.

3.Mr.Mould General Mould For Reference

| In-house processing equipment available | NC milling machine |

| engraving machine | |

| EDM (Elctron Discharge Machining) | |

| wire cutting machine | |

| drilling machine | |

| grinding machine | |

| milling machine | |

| CNC processing center | |

| Solutions/services provided | mould design |

| mould fabrication | |

| and injection and blow moulding processing | |

| Selection of Materials | 718 |

| 718H | |

| P20 | |

| 2738 | |

| 2316 | |

| S136 | |

| Die carrier spec | 50S preharden > 30 HRC |

| Cooling system design | optimized recirculation cooling system, which improve productivity and reduce cost in process of production |

| Mid-stage treatment | hardening and tempering for improving hardness |

| Late-stage treatment | nitriding (hardness>45 HRC); vacuum hardening (hardness>50HRC) |

| Life span of mold | > 500,000 cycles (with regular service) |

| Packaging and handling | Once finished and passed inspection, moulds are properly packed with reinforced package for shipping, with rust prevention processed and mold lock installed |

| Warranty | all the moulds we manufactured are covered with one-year warranty after being delivered for service |

WHY CHOOSE MR.MOULD?

| 1 | We are the manufacturer which offer products with competitive price to trade companies. |

| 2 | We have more than 10 years manufacture experience |

| 3 | We design and produce what you request. |

| 4 | Certification of ISO9001,CE. We are good quality in management and product. |

| 5 | The fastest delivery speed.(15 working days) |

| 6 | Perfect after sale maintenance. |

| 7 | Wholesales & Large order have discount. |

| Packing |

Outside package : Standard wooden cases; Inner package : Stretch waterproof film & Each Mold painted anti-rust oil.3. Spare parts together with the mold shipment. |

| Delivery time | 30 days after receipt the deposit |