- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Product 2021

-

Weight (KG):

-

560 KG

-

Applicable Industries:

-

Furniture Factory, Cabinet&Door Manufacturer

-

Planer:

-

C300

-

Working tables:

-

300*1500mm

-

Cutterblock diameter:

-

70mm

-

Cutterblock rotation speed:

-

5700rpm

-

N. of knives:

-

3

-

knives dimensions:

-

300x25x3

-

Thicknesser:

-

C300

-

Working table:

-

300x660mm

-

Max. working height:

-

220mm

-

Min. working height:

-

4mm

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

GIANTWAY

-

Machine Type:

-

Woodworking machine

-

Marketing Type:

-

Hot Product 2021

-

Weight (KG):

-

560 KG

-

Applicable Industries:

-

Furniture Factory, Cabinet&Door Manufacturer

-

Planer:

-

C300

-

Working tables:

-

300*1500mm

-

Cutterblock diameter:

-

70mm

-

Cutterblock rotation speed:

-

5700rpm

-

N. of knives:

-

3

-

knives dimensions:

-

300x25x3

-

Thicknesser:

-

C300

-

Working table:

-

300x660mm

-

Max. working height:

-

220mm

-

Min. working height:

-

4mm

Products Description

Machine Specifications

|

Planer

|

C300

|

Unit

|

|

Working tables

|

300x1500

|

mm

|

|

Cutterblock diameter

|

70

|

mm

|

|

Cutterblock rotation speed

|

5700

|

r.p.m

|

|

N. of knives

|

3

|

n°

|

|

knives dimensions

|

300x25x3

|

mm

|

|

Max table adjustement

|

4

|

mm

|

|

Thicknesser

|

C300

|

Unit

|

|

Working table

|

300x660

|

mm

|

|

Feed speed

|

7

|

m/1'

|

|

Max. working height

|

220

|

mm

|

|

Min. working height

|

4

|

mm

|

|

Cutterblock rotation speed

|

5700

|

r.p.m.

|

|

Max. cutting depth

|

4

|

mm

|

|

Mortiser

|

C300

|

Unit

|

|

Working table

|

250x500

|

mm

|

|

Longitudinal stroke

|

205

|

mm

|

|

Trasversal stroke

|

95

|

mm

|

|

Vertical stroke

|

90

|

mm

|

|

Churck

|

16

|

mm

|

|

Churck rotation speed

|

5700

|

r.p.m.

|

|

Circular saw

|

C300

|

Unit

|

|

Working table

|

220x1000

|

mm

|

|

Shaft rotation speed

|

4500

|

r.p.m.

|

|

Blade diameter

|

250

|

mm

|

|

Blade bora diameter

|

30

|

mm

|

|

Cutting height 90°

|

75

|

mm

|

|

Max. distance between blade and fence

|

600

|

mm

|

|

Blade inclination

|

45°

|

0°

|

|

Max cutting height 45°

|

50

|

mm

|

|

Shaft rotation speed engraver

|

7000

|

r.p.m.

|

|

Engraver blade diameter

|

90

|

mm

|

|

Engraver blade bora diameter

|

22

|

mm

|

|

Shaper

|

C300

|

Unit

|

|

Working tables

|

220x1000

|

mm

|

|

Shaft rotation speeds

|

2000/3100/4400/7000

|

r.p.m.

|

|

Standard shaft diameter

|

30 (32/35/50 optional)

|

mm

|

|

Spindle lenght

|

105

|

mm

|

|

Shaft vertical stroke

|

115

|

mm

|

|

Max. tool diameter

|

160

|

mm

|

|

Max. tenoning depth

|

55

|

mm

|

|

Tenoning carriage

|

C300

|

Unit

|

|

Carriage dimensions

|

1250x315

|

mm

|

|

Carriage stroke

|

1250/1600

|

mm

|

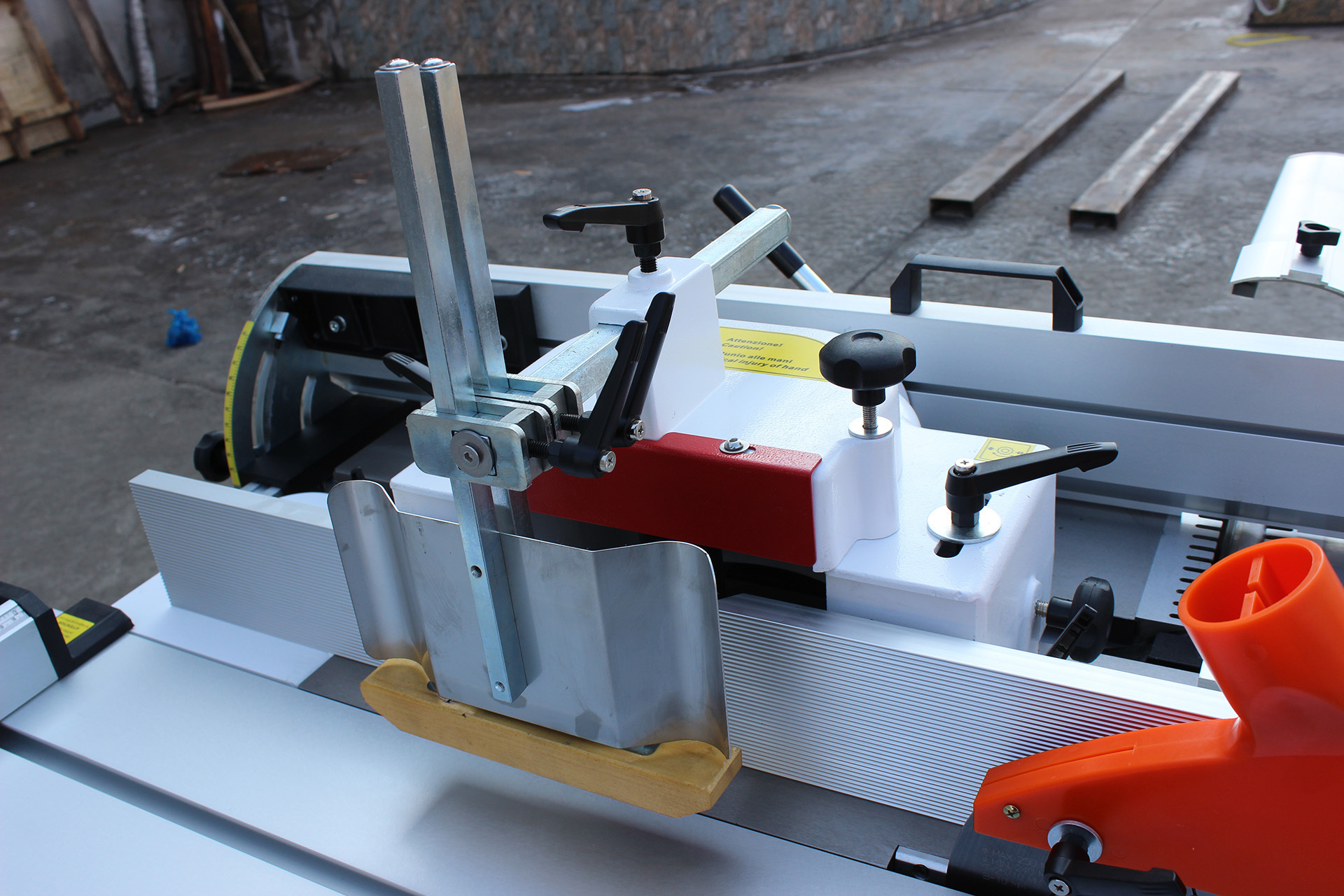

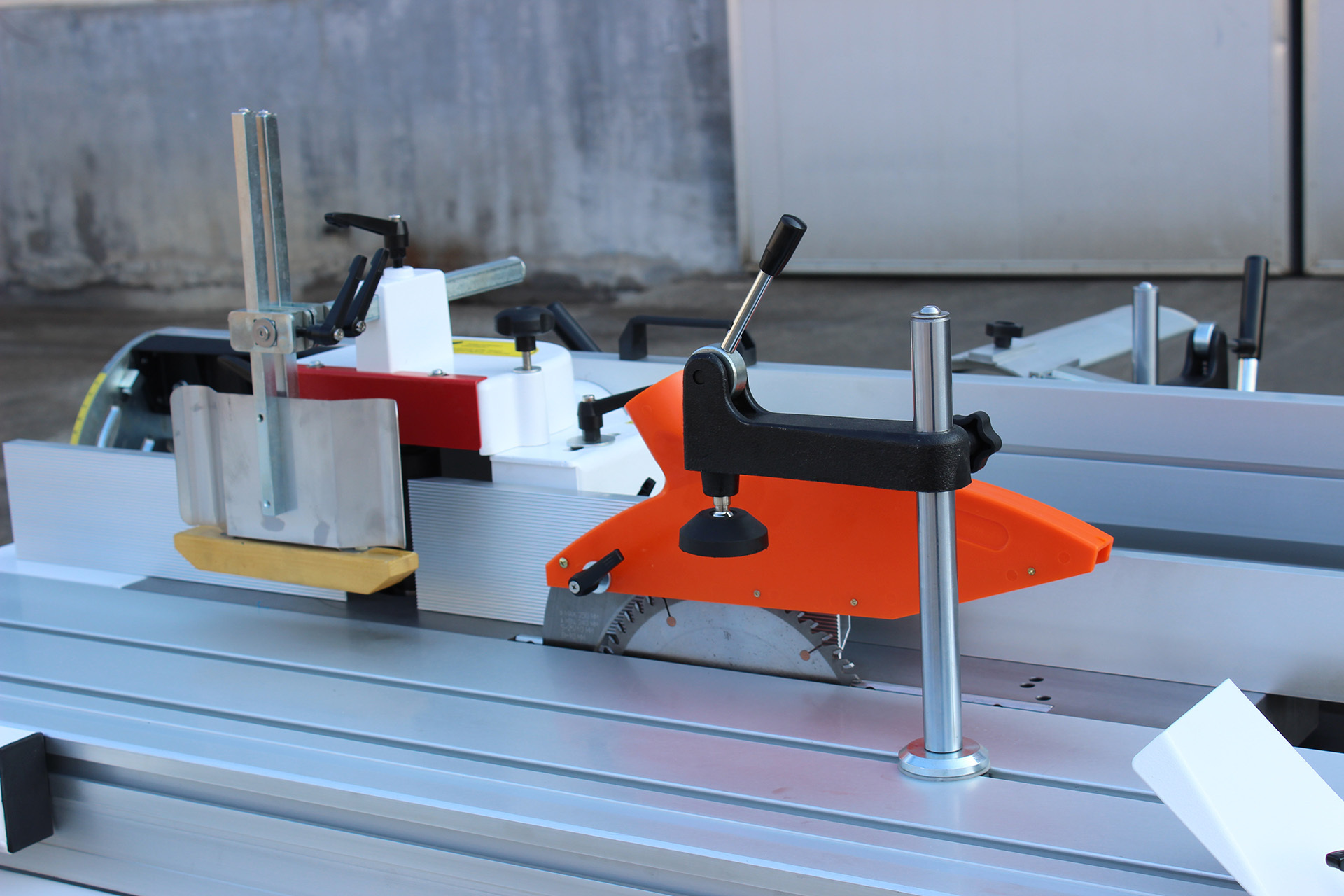

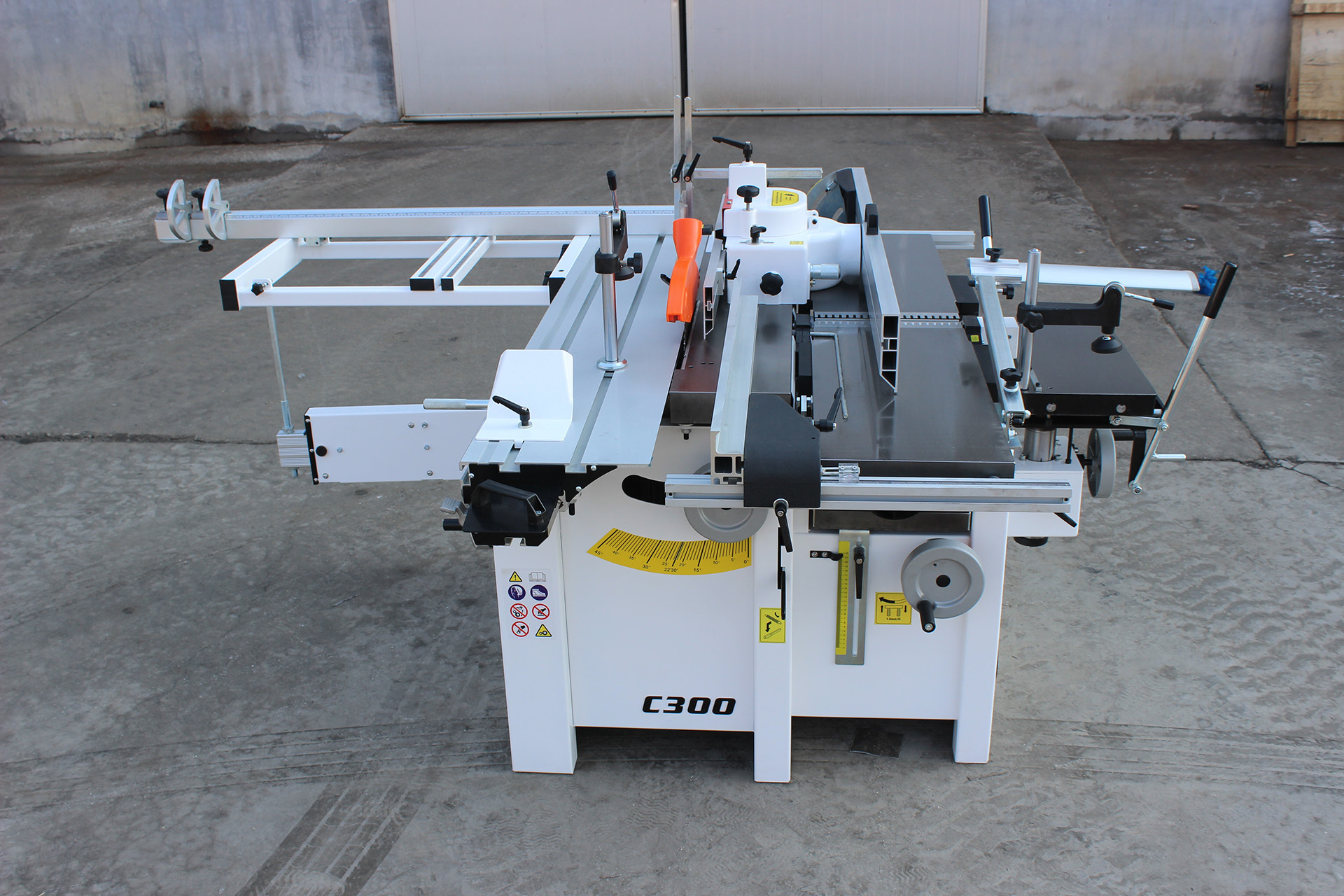

Features:

The C300 Combined Machine has been specifically designed be an industrial standard machine, but at a size intended for the factory and small professional workshop. This industrially rated machine features a table saw and sliding table, planer, thicknesser and spindle moulder unit. The cast iron construction, accurate cross cut fence and superb build quality put this machine in a class of its own.

Being a professional standard machine, the C300 of course is fully adjustable and the accuracy is second to none. As far as accuracy goes it will not even be bettered by full sized industrial machines. With three independent class 1 motors providing ample power, changing function can be done with the flick of a switch rather than the going through the laborious task of changing belts.

The saw utilises a sliding beam which runs along side the blade like a panel saw. By running the beam this close to the blade,100% accuracy is assured.

The planer thicknessing function, again is of the highest quality, extremely powerful, accurate and the end result is simply

sublime. The inward swing of the thicknessing unit keeps this machine compact in every function,whilst the cast iron construction means even heavy pieces can be handled confidently. Several further options are also available, each machine can therefore be tailored to the users specific needs. These optionsinclude; heavy duty morticing unit, spindle moulder ring fence, power feeder and tenoning hood.

Being a professional standard machine, the C300 of course is fully adjustable and the accuracy is second to none. As far as accuracy goes it will not even be bettered by full sized industrial machines. With three independent class 1 motors providing ample power, changing function can be done with the flick of a switch rather than the going through the laborious task of changing belts.

The saw utilises a sliding beam which runs along side the blade like a panel saw. By running the beam this close to the blade,100% accuracy is assured.

The planer thicknessing function, again is of the highest quality, extremely powerful, accurate and the end result is simply

sublime. The inward swing of the thicknessing unit keeps this machine compact in every function,whilst the cast iron construction means even heavy pieces can be handled confidently. Several further options are also available, each machine can therefore be tailored to the users specific needs. These optionsinclude; heavy duty morticing unit, spindle moulder ring fence, power feeder and tenoning hood.

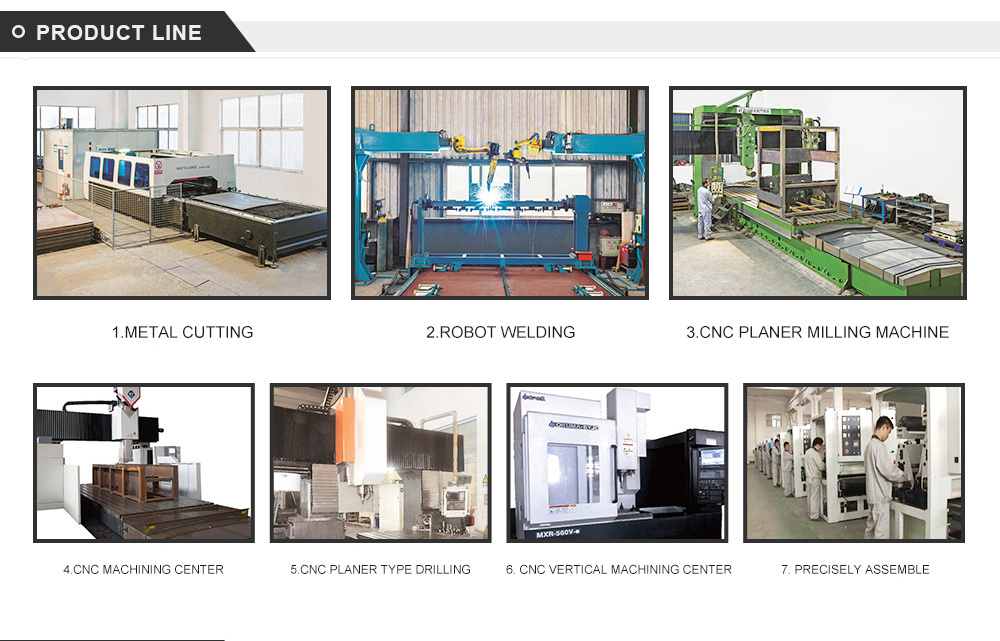

Product Line

Our Company

Quality Testing

Certification

Our Partner&Exhibition

Packaging&Shipping

FAQ

1.What is a good wide belt sander?

A good wide belt sander should have below characteristics.

1, High precision, a good sander has to do a good calibrating job, after sanding, the thickness tolerance maximum is 0.1mm.

2, Making good surface, a perfect belt sander has to produce a good surface, no sanding marks left on the whole surface.

3, Easy to run and maintenance, a wonderful machine should be easy to operate and no difficulty for maintenance.

4, Working stability and low repair rate, a good wide belt sander has to be a stabilized equipment, with very low repair rate, and guarantee the customers’ production no stop.

5, Long life, an excellent machine need have a long life, Giantway has some machines have been working for more than 20 years

2.

What kind of sanding machine I need to buy?

1, This depends on your product and production capacity. A small work shop maybe need one sanding machine only.

2, For big factories and big production capacity, you need to buy many machines for calibrating job and fine sanding job, you also need to buy lacquer sanders for the sealer sanding job.

3, For big stock removal job, such as jointed panels, bamboo panels, you need to buy the planer sander.

4, For carving boards or pattern boards, you need to buy Giantway brush sanders.

3.

Are you a trade company or manufacturer?

We are a professional sanding machine manufacturer since 1997, before 2005, we are called Qingdao JCH Woodworking Machinery Co., Ltd.. We have 15000 square meters workshop in Qingdao, China, and 200 staffs. We can make more than 1000 sets sanding machine per year, and export 40% to worldwide.

4.

How long is the delivery time?

We usually deliver our goods within 21 days after getting your advance payment. But if the electric power in your country is different with China (380V/ 50hz / 3p), for example, your power is 460V / 60HZ/ 3P, we need 40 days to delivery your goods.

5.

Can you help the customer to install the machines?

Yes, we can. We have 3 options for you:

1, There is a manual book with every machine, you can install the machine with the instruction on the manual. Most customers can do the installation according to the manual.

2, We can provide video service to help you solve all the problems you maybe meet, including the installation, and it is free of charge.

3, We can go to your place to help you install the machines. But you need to pay for the journey cost and USD100 service fees per day.

6.

How is the after sales service?

Our machine guarantee time is 18 months from the BL date, but service is for ever. We can supply call service, internet service, video service at any time. We also can arrange engineers to visit your place and help you to maintain or repair the machine.

Hot Searches