- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Other

-

Application:

-

Other

-

Rated Voltage:

-

1kv

-

Tensile Strength:

-

10.4Mpa

-

Product name:

-

insulation board

-

Color:

-

Black

-

Usage:

-

Electrical Insulation Protection

-

Size:

-

Customized Size

-

Thickness:

-

Customer Demands

-

Feature:

-

High Temperature Resistance

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

insulation board

-

Model Number:

-

insulation board

-

Material:

-

Other

-

Application:

-

Other

-

Rated Voltage:

-

1kv

-

Tensile Strength:

-

10.4Mpa

-

Product name:

-

insulation board

-

Color:

-

Black

-

Usage:

-

Electrical Insulation Protection

-

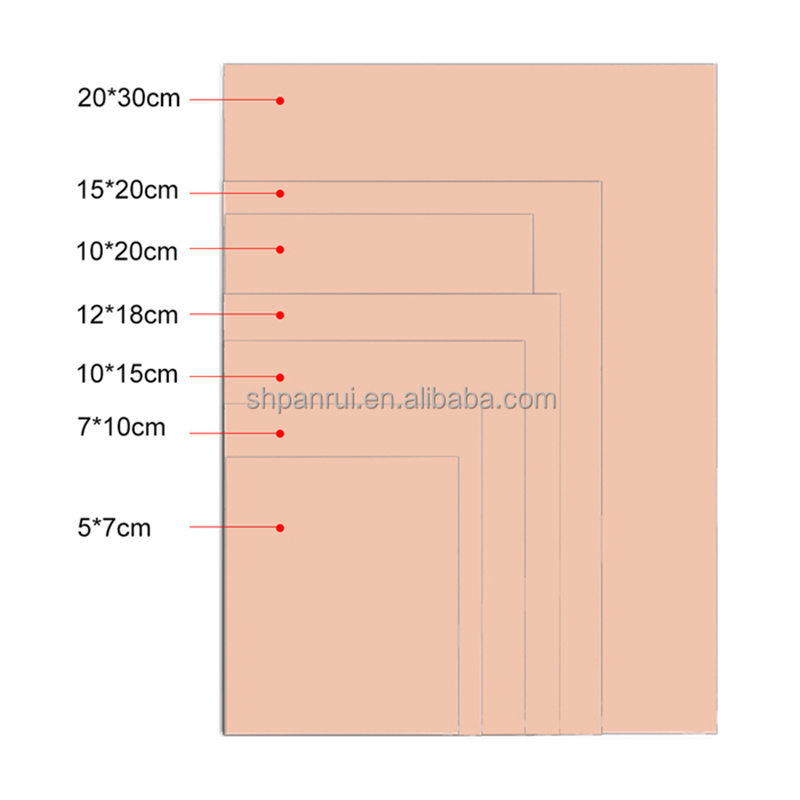

Size:

-

Customized Size

-

Thickness:

-

Customer Demands

-

Feature:

-

High Temperature Resistance

Product Description

Specification

|

item

|

value

|

|

Place of Origin

|

China

|

|

|

Shanghai

|

|

Brand Name

|

FR4 Copper Clad Laminate Sheet Plate

|

|

Model Number

|

FR4 Copper Clad Laminate Sheet Plate

|

|

Type

|

Insulation Sheet

|

|

Material

|

Fiberglass, copper foil, Epoxy resin,FR4

|

|

Application

|

High Voltage

|

|

Rated Voltage

|

40KV

|

|

Tensile Strength

|

Excellent

|

|

Product Name

|

FR4 Copper Clad Laminate Sheet Plate

|

|

Color

|

Customized

|

|

Certification

|

ISO9001:2000

|

|

Thickness

|

ODM/0.05mm~4.0mm

|

|

Keywords

|

FR4 COPPER

|

|

Feature

|

High mechanical

|

|

Working temperature

|

45~+220 Degree Celsius

|

|

Density

|

1.8-2.1g/cm3

|

|

Flammability

|

V-0

|

|

OEM

|

Accept

|

Products & Services

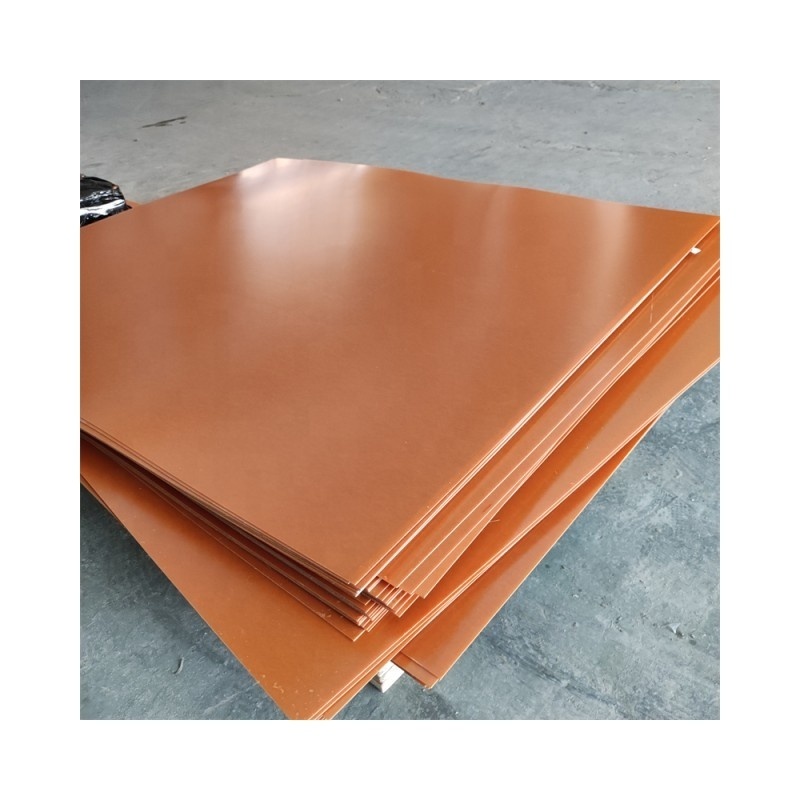

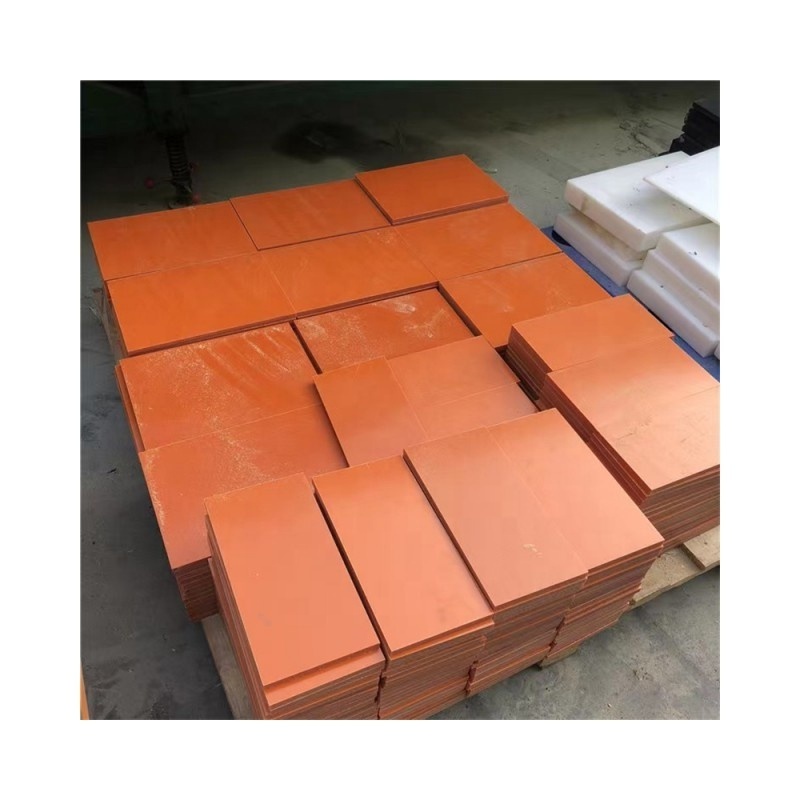

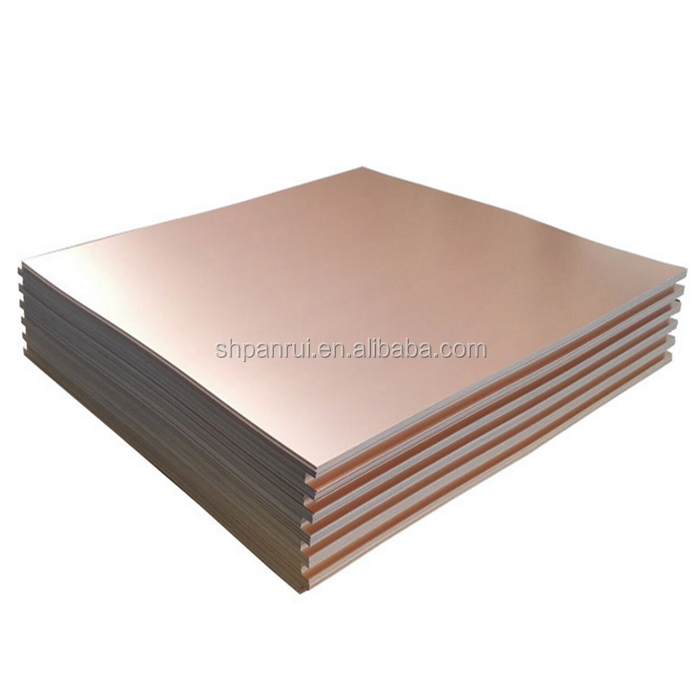

XPC Copper clad laminated sheet/CCL consist of bleached wood pulp paper, impregnated with modified phenolic resin and clad with electrolytic copper foil.It has high dimension stability, good punching behavior at low temperature, high thermal resistance and are widely used for computers, telephones, Hi-Fi acoustic devices, electronic toys and etc.

Note:Different thickness copper foil in one side or double sides can be supplied. 18um,25um,35um,70um

Copper clad laminated board - also known as electronic circuit board substrate. Based on FR-4 epoxy resin board, it is formed by hot pressing of copper foil on one or both sides of the FR-4 sheet.

Advantages

1, Good flatness, smooth surface, no pits, standard thickness tolerance.

2, Low water absorption, good moisture resistance and dielectric properties .

3, Good electrical performance in dry or wet conditions.

4, High mechanical properties, good processability: punching, drilling, machining and cutting.

5, Good mechanical workability.

6, Stable electric performance in high temperature.

Application:

Copper clad laminate (CCL)is the basic material in the electronics industry. It is mainly used in the manufacture of printed circuit boards (PCBs), and it is widely used in televisions, radios, computers, mobile communications and other electronic products.

Note:Different thickness copper foil in one side or double sides can be supplied. 18um,25um,35um,70um

Copper clad laminated board - also known as electronic circuit board substrate. Based on FR-4 epoxy resin board, it is formed by hot pressing of copper foil on one or both sides of the FR-4 sheet.

Advantages

1, Good flatness, smooth surface, no pits, standard thickness tolerance.

2, Low water absorption, good moisture resistance and dielectric properties .

3, Good electrical performance in dry or wet conditions.

4, High mechanical properties, good processability: punching, drilling, machining and cutting.

5, Good mechanical workability.

6, Stable electric performance in high temperature.

Application:

Copper clad laminate (CCL)is the basic material in the electronics industry. It is mainly used in the manufacture of printed circuit boards (PCBs), and it is widely used in televisions, radios, computers, mobile communications and other electronic products.

3021 3025

3021 Paper-based phenolic laminated sheets are the most commonly seen laminates, as well as having the widest applications and largest usage.

3025

Phenolic cotton cloth laminated sheet are manufactured by modified phenolic resin as binder and pure cotton fabric as reinforcement. They have exceptionally good heat resistance and will not creep under high temperature conditions.

Key Features and Benefits

•Good mechanical strength.

•Good wear peoperties.

•Good electrical properties.

•Good dimensional stability.

•Good dielectric loss properties.

Key Features and Benefits

•Excellent mechanical properties

•High impact strength

•High mechanical applications

•High electrical properties.

Applications

•Cams, gears, slides, special machinery surfaces, insulators, relays, switches, terminal strips.

•transformers, electric motors, cabinets, control boxes, electric switches, household appliances, railway, automobile, computer and medical appliance

3021 Paper-based phenolic laminated sheets are the most commonly seen laminates, as well as having the widest applications and largest usage.

3025

Phenolic cotton cloth laminated sheet are manufactured by modified phenolic resin as binder and pure cotton fabric as reinforcement. They have exceptionally good heat resistance and will not creep under high temperature conditions.

Key Features and Benefits

•Good mechanical strength.

•Good wear peoperties.

•Good electrical properties.

•Good dimensional stability.

•Good dielectric loss properties.

Key Features and Benefits

•Excellent mechanical properties

•High impact strength

•High mechanical applications

•High electrical properties.

Applications

•Cams, gears, slides, special machinery surfaces, insulators, relays, switches, terminal strips.

•transformers, electric motors, cabinets, control boxes, electric switches, household appliances, railway, automobile, computer and medical appliance

Processing Conditions

Traditional Iaminator

Temperature:160-165℃

Pressure:2-3mpa=(40-60kg/SQMCM)

Time:40-60min

Baking:unnecessary

High-speed liminator:

Temperature:165-175℃

Pressure:1.5-2.5mpa=(30-40kg/SQCM)

Time:5-10min

Baking:160℃*60min

Traditional Iaminator

Temperature:160-165℃

Pressure:2-3mpa=(40-60kg/SQMCM)

Time:40-60min

Baking:unnecessary

High-speed liminator:

Temperature:165-175℃

Pressure:1.5-2.5mpa=(30-40kg/SQCM)

Time:5-10min

Baking:160℃*60min

Product features

1.superior heat dissipation

2.High peel strength

3.Excellent thermal reliability and insulation reliability

4.Excellent processablilty

2.High peel strength

3.Excellent thermal reliability and insulation reliability

4.Excellent processablilty

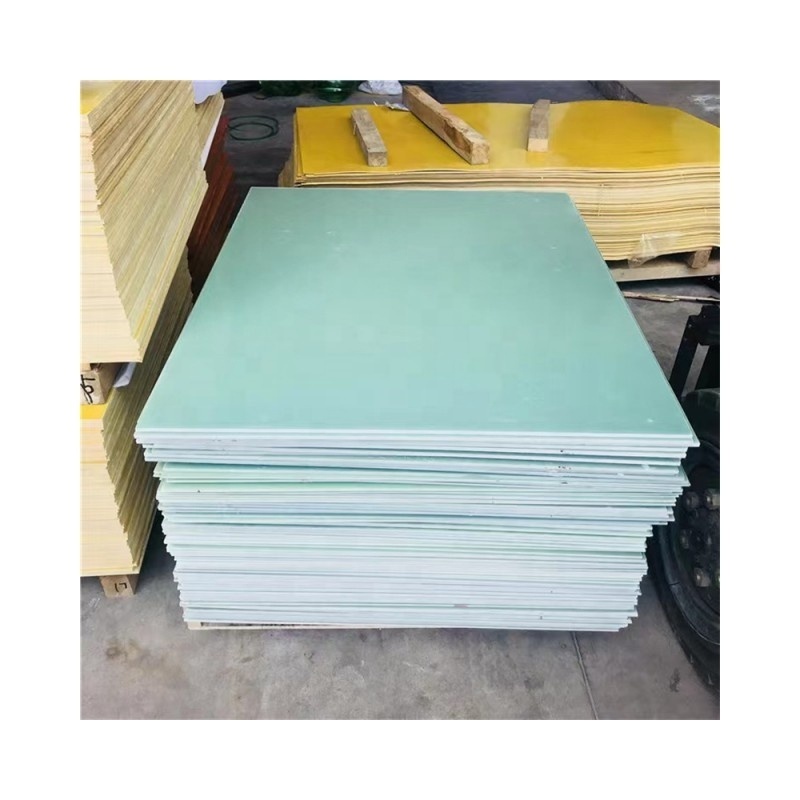

Epoxy Glass Cloth Laminate 3240

Epoxy glass cloth laminated sheets(industry laminate sheet,Epoxy sheet) are made of alkali-free E-glass cloth impregnated with epoxy resins and phenolic resins by processing under heat and pressure. Epoxy glass cloth sheet can be processed into all kinds of insulation parts, The products are widely used transformers, electric motors, cabinets, control boxes, electric switches,household appliances, railway, automobile, computer and medical appliance,etc.

3240 Epoxy Phenolic Glass Cloth Laminate Sheet

Epoxy-phenolic glass cloth laminated sheet (3240 sheet)are made of alkali-free E-glass cloth impregnated with epoxy resins and phenolic resins by processing under heat and pressure.

Epoxy glass cloth sheet can be processed into all kinds of insulation parts, The products are widely used transformers, electric motors, cabinets, control boxes, electric switches, household appliances, railway, automobile, computer and medical appliance,etc.

3240 Epoxy Phenolic Glass Cloth Laminate Sheet

Epoxy-phenolic glass cloth laminated sheet (3240 sheet)are made of alkali-free E-glass cloth impregnated with epoxy resins and phenolic resins by processing under heat and pressure.

Epoxy glass cloth sheet can be processed into all kinds of insulation parts, The products are widely used transformers, electric motors, cabinets, control boxes, electric switches, household appliances, railway, automobile, computer and medical appliance,etc.

3240B and 3240C are similar to 3240, but with lower properties.

Hot Sale

Hot Searches