Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Gansu, China

-

Brand Name:

-

Lantai

-

Voltage:

-

Depends on customer

-

Dimension(L*W*H):

-

Depends on design

-

Power (kW):

-

150

-

Weight:

-

10000 KG

-

Core Components:

-

Other

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

L/D Ratio:

-

32-48

-

Motor Brand:

-

SIMENZ

-

Capacity:

-

5-85KG

-

Rotary Speed:

-

500/600 rpm

-

Power(W):

-

200/75 kW

-

Automatic Grade:

-

Auto

-

After Warranty Service:

-

Field maintenance and repair service

-

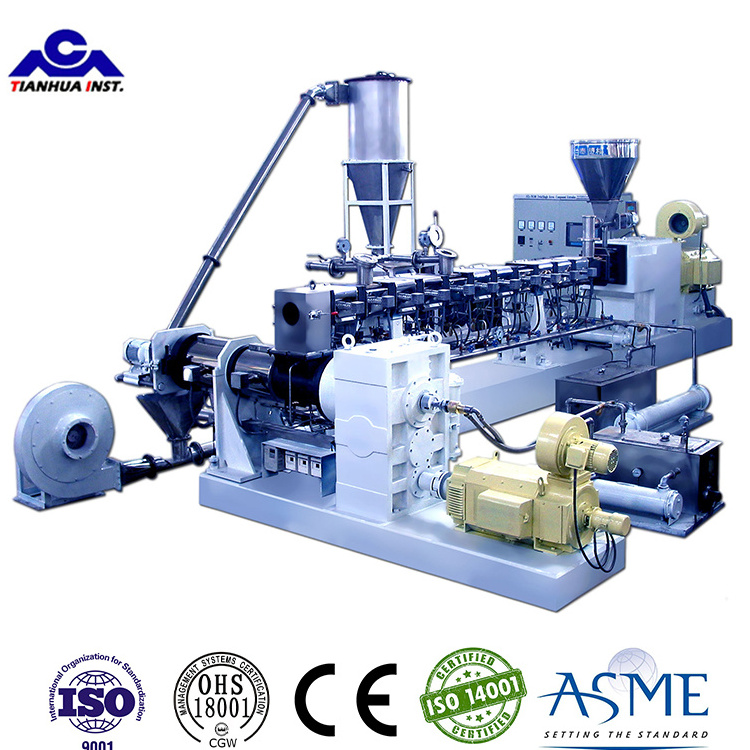

Certification:

-

ISO9001, CE,SGS, ASME

-

Usage:

-

Plastic Extrusion

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

28:1

-

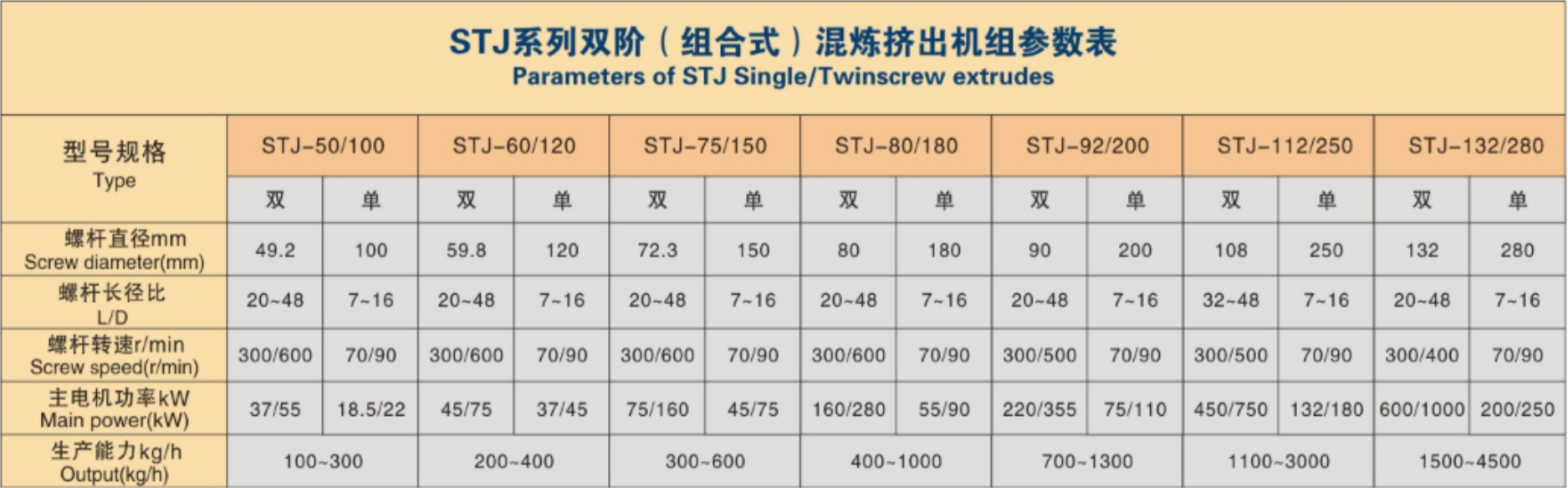

Screw diameter (mm):

-

72.3 mm

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Gansu, China

-

Brand Name:

-

Lantai

-

Voltage:

-

Depends on customer

-

Dimension(L*W*H):

-

Depends on design

-

Power (kW):

-

150

-

Weight:

-

10000 KG

-

Core Components:

-

Other

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

L/D Ratio:

-

32-48

-

Motor Brand:

-

SIMENZ

-

Capacity:

-

5-85KG

-

Rotary Speed:

-

500/600 rpm

-

Power(W):

-

200/75 kW

-

Automatic Grade:

-

Auto

-

After Warranty Service:

-

Field maintenance and repair service

-

Certification:

-

ISO9001, CE,SGS, ASME

-

Usage:

-

Plastic Extrusion

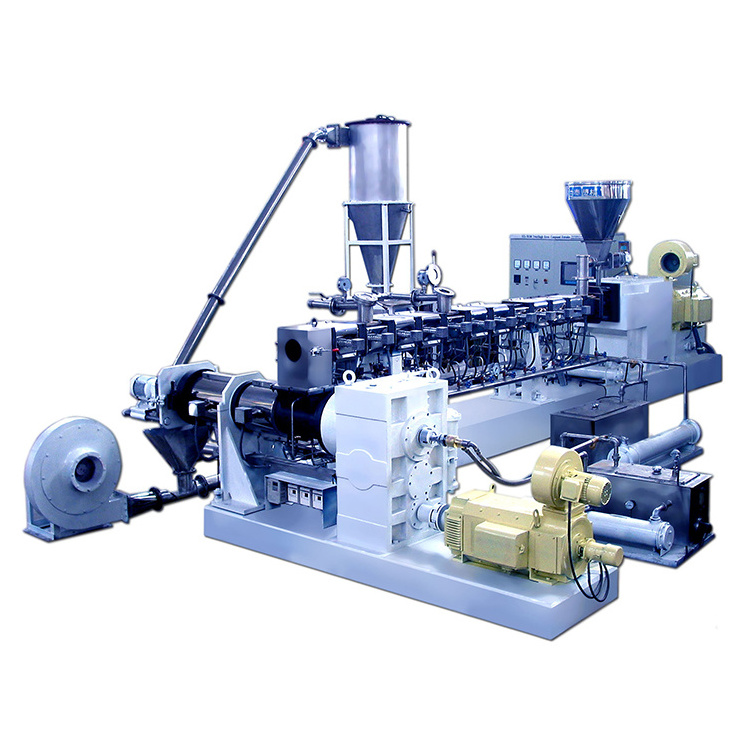

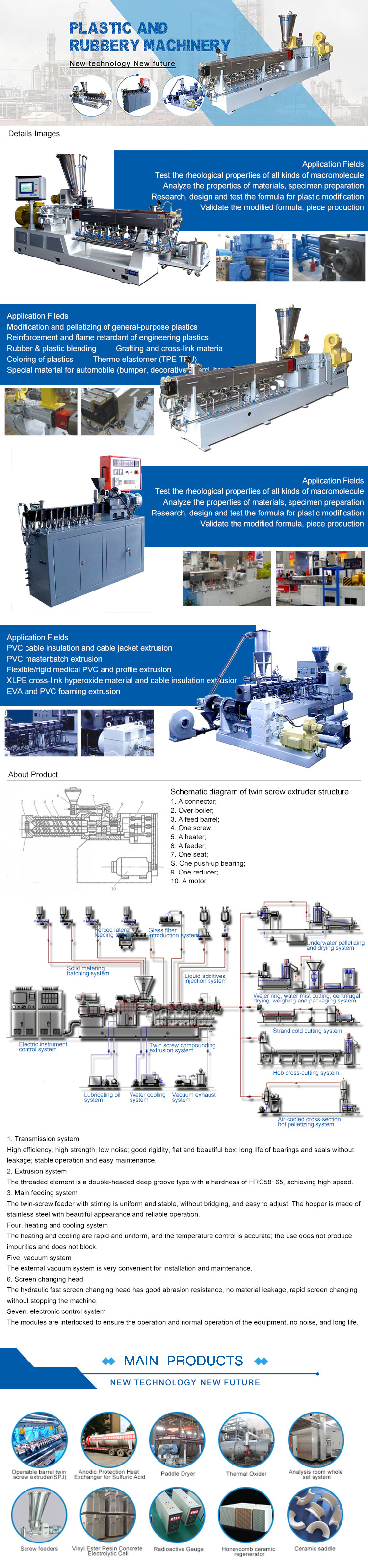

STJ Co-rotating Twin/single Screw Extruding Line

The feature of compounding-extruder

The twin-screw extruder is modular designed. We can change the structure of screws and barrels on the basis of various requirements from the customers. The overall structures of single-screw vary from different material properties and extruding process. Under the premise in guaranteed yield and compounding effect, energy consumption is reduced significantly by adopting optimum design method. This kind of extruder is mainly used for thermal sensitvity polymer and environmental degradable polymer. It can also be used for profile extrusion in one stage which needs high extruding pressure.

The Twin-screw and single-screw extruders have complementary advantages. The Twin-screw extruder is mainly used for forcing conveying, high efficiency compounding and shearing dispersing. Because of no back pressure and backflow, smalldie pressure and lower fill ratio , the materials won't be overheated in Twin-screw extruder. The single screw is mainly used for extruding. The speed and the shearing force are weaker so that the materials won't be degraded.

The single-screw extruder is cooled by independent water cooling system which can control screw temperature, so that the melt would not stay on the screw and the melt will flow steadily.

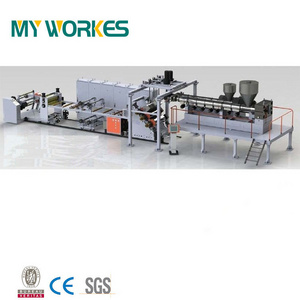

Application Fileds:

1、PVC cable insulation and cable jacket extrusion

2、PVC masterbatch extrusion

3、Flexible/rigid medical PVC and profile extrusion

4、XLPE cross-link hyperoxide material and cable insulation extrusion

5、EVA and PVC foaming extrusion

6、Automobile special materials-EVA sheet compounding and extrusion in one stage

7、Degradable master batch and sheet extrusion

8、LSZH extrusion

9、Highly-extended master batch extrusion

10、Semi-conducting and semi-insulating material extrusion

11、Sheet, plate and profile extrusion

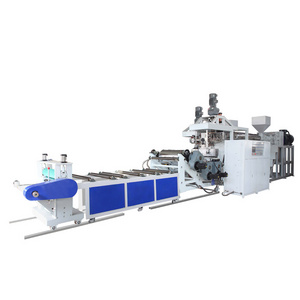

Advantages:

1、 Lantai twin-screw compounding extruders possess space saving function, elegant and compact configuration.

2、This type of twin screw extruder adopts world-class inverter and comprehensive alarm system.

3、 Its reducing torque distribution system can ensure quiet running.

2、This type of twin screw extruder adopts world-class inverter and comprehensive alarm system.

3、 Its reducing torque distribution system can ensure quiet running.

4、Twin-screw compounding extruder is equipped with flexible and maintenance-free air-cooling system.

5、This kind of twin screw extruder is well designed and elaborately manufactured.

5、This kind of twin screw extruder is well designed and elaborately manufactured.

|

Series

|

SHJ,STJ,SPJ,SSJ,SFJ,SZJ multiple co-rotating twin-screw extrusion

|

|

|

Rubber and plastic blending

|

Typical products: PP, PE, PS+SBS; PP, PA+EPDM; PP+NBR; EVA+silicone rubber: TPR thermoplastic elastomer, etc.

|

|

|

Plastic alloy

|

Typical products: PC+ABS, PA+ABS, CPE+ABS, PP+EPDM, PA+EPDM, PP+SBS, etc.

|

|

|

Plastic coloring

|

Typical products: PE, PP, PS, ABS, EVA, PBT, PET, etc. + inorganic or organic pigments.

|

|

|

Fiber reinforcement

|

Typical products: PP, ABS, PC, AS, PBT, PET, PA6, PA66, PPS, POM, etc.+ (long fiber, short fiber, carbon fiber, metal fiber).

|

|

|

High percentage filling

|

General-purpose filling: It is widely used in the filling field of inorganic fillers such as CaCO: (heavy and light), talcum

powder, titanium dioxide, etc. The maximum filling rate is 93%, and good dispersibility is ensured. The volumetric gas content in the particles is within 1% or less. Typical products: PP, PE filled CaCO, inorganic flame retardant Mg(OH), open masterbatch, ferromagnetic material, AMOH), red phosphorus, SbO: filled, helium-based flame retardant filling; PP, PE+CaCO, talc Powder, titanium powder, carbon black, etc.: ABS, PC, PS, etc.+xenon alumina; PP, PA, ABS, etc.+magnetic powder, ceramic powder, iron powder: carbon black masterbatch film and color masterbatch (suitable for various films Production). |

|

|

Special materials for automobiles

|

Typical products: PP, ABSPS, PBT, PET and other reinforced flame-retardant bumpers, instrument panels, battery shells, steering

wheel materials, etc.; PVC sealing strip materials. Special materials for household appliances Typical products: ABS, PP and other color TV sets, refrigerator shells to resist fuel; communication, power cable materials. Thermoplastic elastomer TPR, TPV, EVA. Cross-linked material Polyethylene cross-linked material, cable material, pipe material. |

|

|

|

||

We are pleased to introduce our company as one of the leading exporters of parallel twin screw extruder in China.

Our main business:

1、Energy saving and environmental protection technology and equipment

2、Chemical unit complete set of technology and equipmentPlastic 3、modification technology and equipment

4、Anti-corrosion technology and equipment

5、Automatic instrumentation and control

6、Nondestructive testing and equipment supervision

If you are interested in some of our products, please feel free to visit our website or contact us for more information and pictures. We are looking forward to establishing long-lasting business relationships with you in the near future.

Presales service:

>introducing in detail features and application of the products to customer

>Selecting economical and practical machine & equipment for customer

>Providing operation data of the related machine & equipment

>Providing means of trial performance for customer

Sales service:

>Recommending engineering conditions required for installation of the machine & equipment

>Communicating in time the manufacturing progress of the machine with user

>Providing assistance in technical conditions, screw combination and barrel disposition needed for product

After-sales service:

>Providing on-the-spot technical assistance in installation, commission and training

>Filling in detail customer’s information

>Providing long-term maintenance service and spare parts

>Giving technical support to customer for developing new product

>Providing free maintenance for a year

FAQ:

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME

● Tianhqua is original manufacturer.

● If you interested in our products and we can fulfill your request , you may pay a visit to Tianhua Factory.

● The meaning of visiting supplier, since seeing is believing, Tianhua Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.

HOW DOES Tianhua MACHINE GUARANTEE the QUALITY

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strict control by inspecting personnel.

● Each assembly is in charge by a master who has working experience for more than 15 years

● After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.

THE AFTER-SALE SERVICE OF Tianhua MACHINERY

● After finishing the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

● After the commissioning, we will package the equipment by the standard export package for shipment.

●According to the customer's request, we can arrange our engineers to customers' factories to do the installation and training.

● Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customers' project.

Hot Searches