- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HNOC

-

Dimension(L*W*H):

-

1600 x 770 x 1450mm, 1600 x 600 x 1260mm

-

Weight:

-

450 KG

-

Certification:

-

ISO 9001,CE

-

Product name:

-

bottle shrink wrap machine

-

Packing material:

-

Plastic Film

-

Machine type:

-

Multi-function Packing Machine

-

Packing speed:

-

15~30pcs/min plastic shrink wrap machine

-

Function:

-

Film Packaging Machine

-

Film material:

-

Hot Seal Film

-

Usage:

-

Wrapping Products

-

Packing type:

-

Sleeve Sealing Shrink

-

Advantage:

-

Easy Operation

-

MOQ:

-

1 SET plastic shrink wrap machine

Quick Details

-

Packaging Type:

-

Film

-

Packaging Material:

-

Plastic

-

Driven Type:

-

Electric

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HNOC

-

Dimension(L*W*H):

-

1600 x 770 x 1450mm, 1600 x 600 x 1260mm

-

Weight:

-

450 KG

-

Certification:

-

ISO 9001,CE

-

Product name:

-

bottle shrink wrap machine

-

Packing material:

-

Plastic Film

-

Machine type:

-

Multi-function Packing Machine

-

Packing speed:

-

15~30pcs/min plastic shrink wrap machine

-

Function:

-

Film Packaging Machine

-

Film material:

-

Hot Seal Film

-

Usage:

-

Wrapping Products

-

Packing type:

-

Sleeve Sealing Shrink

-

Advantage:

-

Easy Operation

-

MOQ:

-

1 SET plastic shrink wrap machine

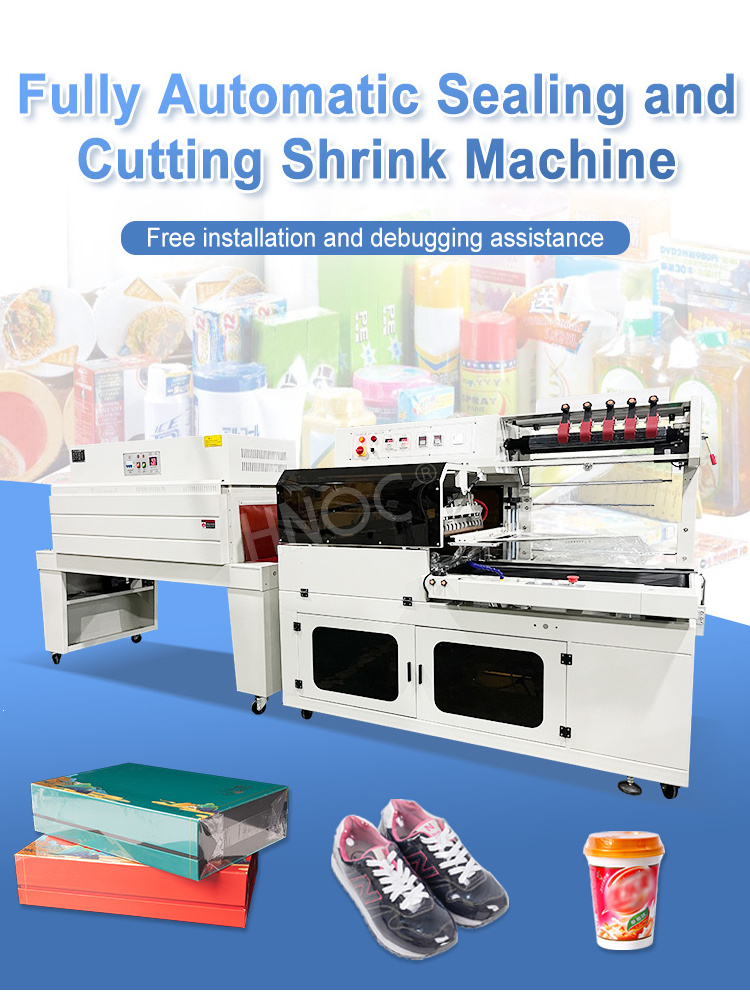

Automatic sealing tunnel type candle magazine sauce mineral water bottle plastic film shrink packaging machine

Product Description

Products Description

'L' type automatic sealing and cutting machine is suitable for large-scale shrink packaging of software, food,cosmetics, printing, ceramics, beverage, hardware and other industries.

'L' type automatic sealing and cutting machine is suitable for large-scale shrink packaging of software, food,cosmetics, printing, ceramics, beverage, hardware and other industries.

|

Voltage

|

220v, 50Hz

|

Max wrapping size

|

450*350*125mm

|

|

Air pressure

|

0.5Mpa

|

Max sealing wrapping size

|

560*440mm

|

|

Power

|

1.35kw

|

Machine dimension

|

1450*730*1360mm

|

|

Wrapping speed

|

15-30 boxs/min

|

Weight

|

300kg

|

|

Voltage

|

380v, 50-60Hz

|

Conveyor belt load

|

30kg

|

|

Power

|

12kw

|

Shrinking furnace size

|

1200*450*220mm

|

|

Machine dimension

|

1700*720*1300mm

|

Weight

|

160kg

|

Main Features

1.Adopt with PLC automatic program circulation control with stable and reliable performance.

2.The original imported guide bar cylinder guarantee correct operation and durable.

3.The inductive switch controls the membrane transfer system to reliably adjust and control the membrane transfer length with less loss.

4.All the transfer system is controlled by frequency changing devices with stable and smooth transfer speed.

5.Unique thermal passage with 2 sets of centrifugal thermal air circulation system that has an equal heat distribution with beautiful and secure shrinkage effect.

6.three layers of heat insulation treatment with good insulating property,quick temperature rise and energy saving.

7.The enhanced cooling shaping passage can quickly turn the packaging membrane into high strength status that is conveniently stored and transported.

8.It is easy to change the packaging combination and bottle type to integrate the multi-function into one machine.

2.The original imported guide bar cylinder guarantee correct operation and durable.

3.The inductive switch controls the membrane transfer system to reliably adjust and control the membrane transfer length with less loss.

4.All the transfer system is controlled by frequency changing devices with stable and smooth transfer speed.

5.Unique thermal passage with 2 sets of centrifugal thermal air circulation system that has an equal heat distribution with beautiful and secure shrinkage effect.

6.three layers of heat insulation treatment with good insulating property,quick temperature rise and energy saving.

7.The enhanced cooling shaping passage can quickly turn the packaging membrane into high strength status that is conveniently stored and transported.

8.It is easy to change the packaging combination and bottle type to integrate the multi-function into one machine.

Specification

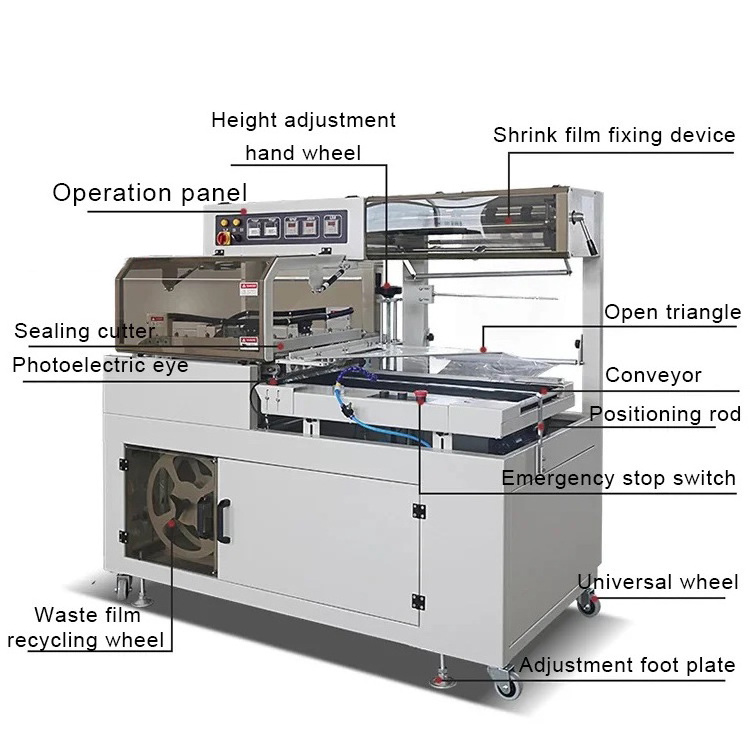

According to the actual height of the product, shake the triangle to a height of about 10 mm above the product.

lt is used to recover the waste side

after cutting the film. After the wastewheel is full, unscrew the handle andtake out the waste film, which is convenient and simple.

The thin product is properly blown into the air to make the shrinking effect more beautiful,and the corners are not easily shrunk.

Put the product separately, do notsquat or stick it in, avoid cutting theproduct.

ln any emergency,the emergency stop switch must be pressed immediately. Hold the red cover and turn it clockwise

Send the film handle, when the film isworn,the handle is topped up. After the film is finished, immediately pull the handle to the position shown in the figure.

safety cover

The working part of the cutter of the sealing and cutting machine is protected by a safety shield to ensure the safety of the user.

Packaging product display

Related Products

Hot Searches