- Product Details

- {{item.text}}

Quick Details

-

Point Location:

-

2 pcs of five megapixels cameras

-

Glue ratio:

-

1:1~3:1

-

Data memory capacity:

-

999 programs

-

Dispensing speed:

-

10-150g/5s(Adjustable)

-

Dispensing Precision:

-

±0.1mm

-

Maximum Running Speed:

-

800mm/s

-

Running Precision:

-

±0.02mm

-

Control:

-

PC+Motion control card

-

Dimension:

-

1465*1495*1900mm

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ZCX

-

X/Y/Z working range:

-

X* Y* Z: 820*320*70mm

-

Point Location:

-

2 pcs of five megapixels cameras

-

Glue ratio:

-

1:1~3:1

-

Data memory capacity:

-

999 programs

-

Dispensing speed:

-

10-150g/5s(Adjustable)

-

Dispensing Precision:

-

±0.1mm

-

Maximum Running Speed:

-

800mm/s

-

Running Precision:

-

±0.02mm

-

Control:

-

PC+Motion control card

-

Dimension:

-

1465*1495*1900mm

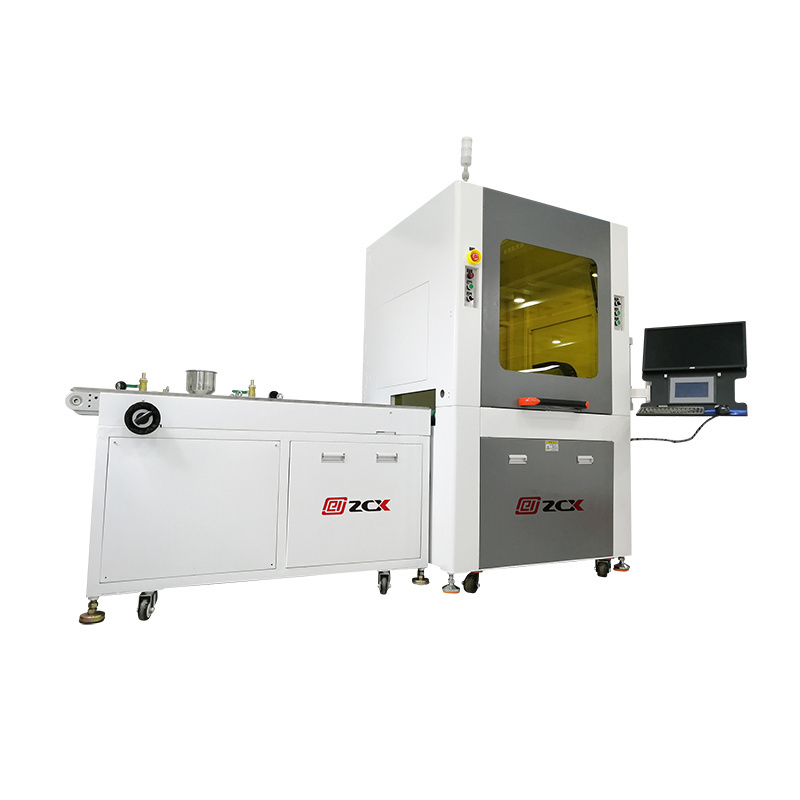

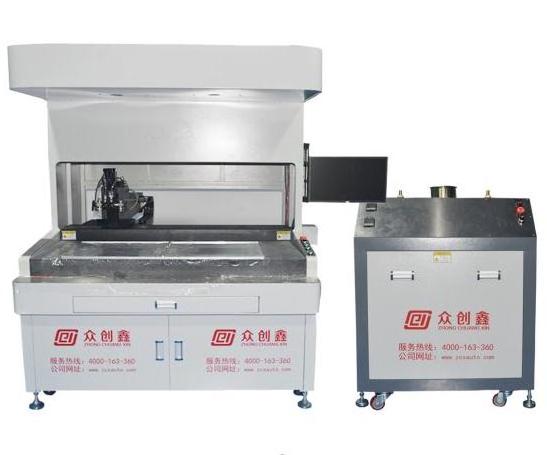

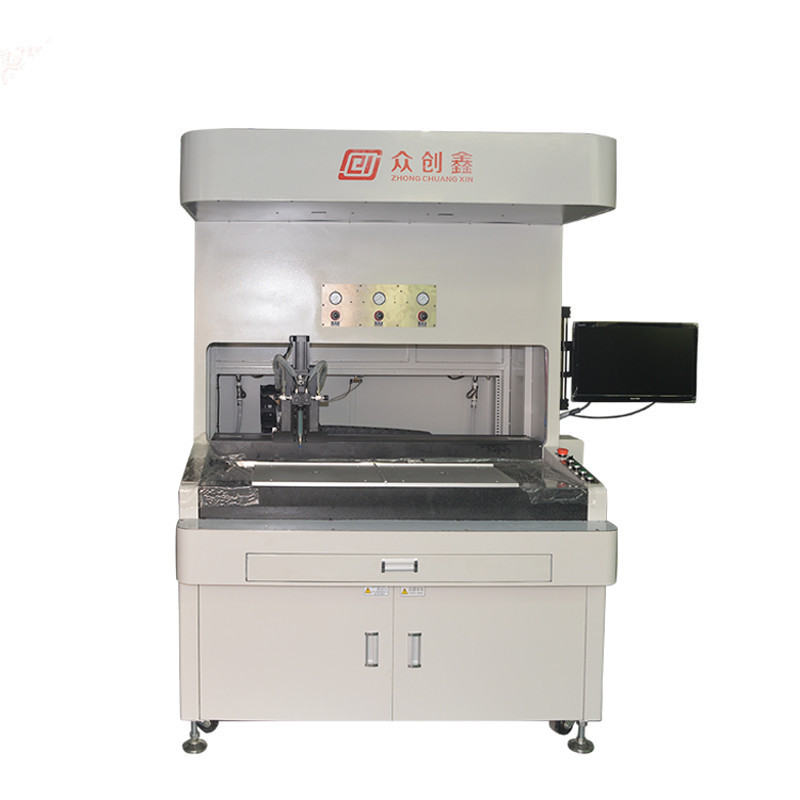

Servo motor and lead screw motion high precision ccd automatic doming visual glue dispenser machine

Spec.

| CCD visual 2 components glue dispensing machine | ||||||

| Model | ZCX-SJ400B | ZCX-SJ500B | ||||

| Axis(mm) | X | 820 | 820 | |||

| Y | 320 | 320 | ||||

| Z | 100 | 100 | ||||

| Dimension(mm) | L | 1350 | 1460 | |||

| W | 1350 | 1350 | ||||

| H | 1765 | 1960 | ||||

| Weight(kg) | 1000 | 1100 | ||||

| Package volum(CBM) | 4.5 | 5.5 | ||||

| Working platform | 400*300 double | 500*400 double | ||||

| Rated power consumption | 380/220/110V 50/60Hz 3500W (Optional) | |||||

| Moving Speed | 500mm/s(Max 800mm/s not suggested) | |||||

| Working distance | X* Y* Z: 820*320*100mm, double working platform | |||||

| Moving Precise | ±0.01mm | |||||

| Moving Path | Point, line, square, circle, arc,dome | |||||

| Glue mixing ratio | 1:1~10:1 | |||||

| Potting Speed | 10-150g/5s(Adjustable) | |||||

| Potting Precise | Amount±1%, Ratio:±1% | |||||

| Air Pressure | 0.5-0.8MPa | |||||

| Head Sealing pressure | MAX≤2.6Mpa | |||||

| Glue water viscosity | <10000Mpas (inquiry for above) | |||||

| Operation Method | Auto, Manual | |||||

| Program Method | CCD Visual Teaching Program | |||||

| Electronic Control System |

Smart control card+PLC+Touch Screen

(Program setting, modify, save) |

|||||

| Glue Stop System | A, B Glue independent movement auto resorption system | |||||

| Mixing Stirring System | High speed dynamic stirring mixing device(static option) | |||||

| Valve | solenoid valve/Piezoelectric valve/nozzel optional | |||||

| Glue ratio control | High precise metering pump | |||||

| A,B glue supply system | A | High precise gear/screw pump 6-12CC |

Bucket

stirring optional |

Heating

optional |

20-50L

Customizable |

|

| B | High precise pressure gear/screw pump 0.6-2.4CC | |||||

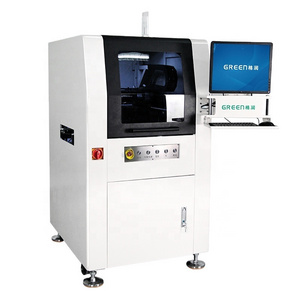

This glue dispensing & coating machine is suitable for high efficiency, high operation precision, high glue proportion production process; mainly used in: crafts, label signs, wall stickers, electronic products and other industries glue dispensing process.

Main features:

1. Use Windows2000/XP English-Chinese operation interface, easy to understand and learn;

2. There are drawing point, line, surface, arc, circle. Irregular curve continuous complement and three axis linkage and other functions;

3. The storage capacity of the hard disk is large, and the software has the functions of regional array, translation and rotation operation;

4. The glue amount, thickness, dispense speed, starting and finishing time can be set. Also, the amount of glue is stable, won’t be leaked;

5. Can be imported the AUTO CAD file to simplify the operation;

6. The CCD auxiliary program editor and teaching function can trace the coordinate locus in real time that helps to shorten the programming time and greatly improve the programming efficiency;

7. Can be selected the double working platform design to save the time of putting and taking the artifacts, or use together with the automatic feeding and conveying machine to increase production capacity and competitive advantage of enterprises;

8. According to the process needs, you can install the workbench positioning PIN, glue gun or floor heating control device;

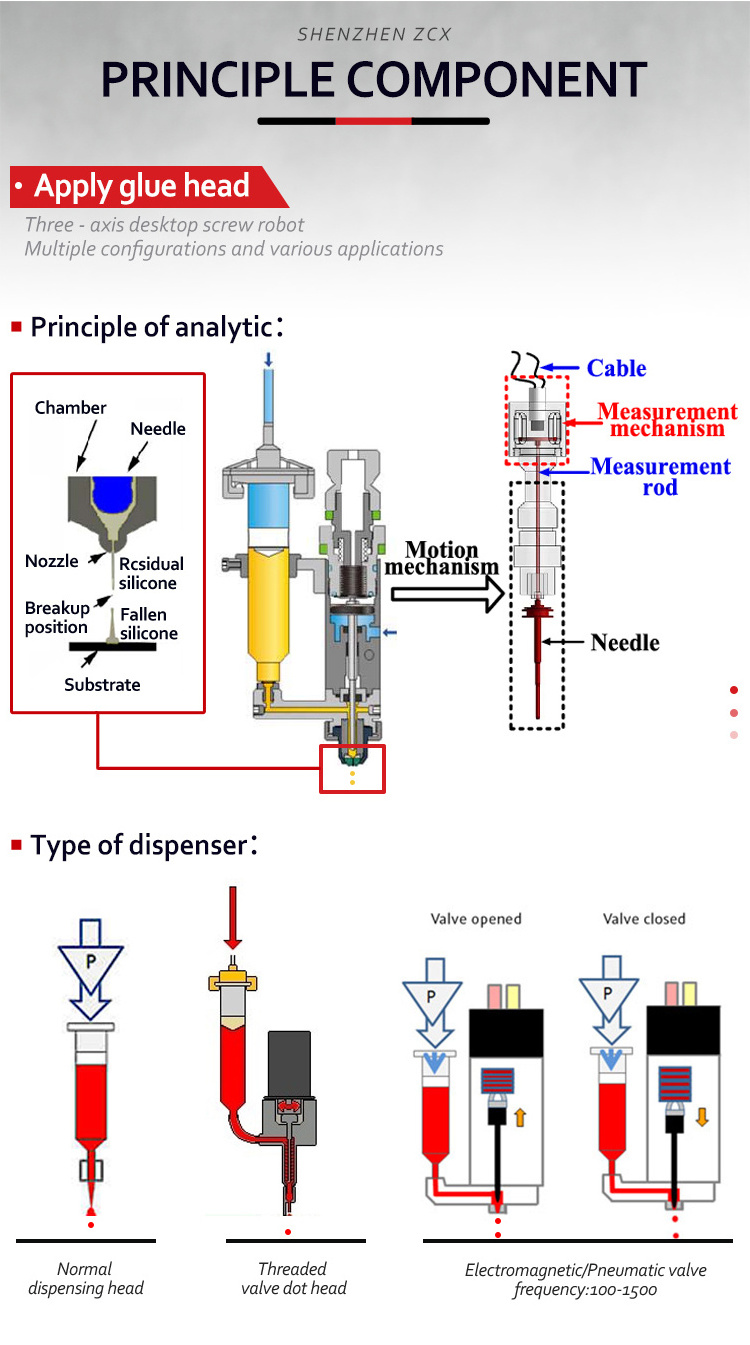

Dispensing valve principle & structure:

There are variaty of configurations for different technique processing. Different glue and glue ratio,substrate,surface, program or dispensing type may effect on the configurations of the machine.

So provide glue TDS to us is important.

1. Plenty options of configurations

2. Fit for various of glue

3. Match for most of processing of production

We have well experienced sales man, please do not hesitate to tell him your requirments, they will provide you the best solution right now!