- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Cutting Forestry Wood Log Waste

-

Name:

-

Wood Chipper Chips Making Machine

-

Power:

-

55kw

-

Usage:

-

Wood Shredder Cutting Wood Branch

-

Raw material:

-

Waste Wood

-

Feature:

-

High Efficiency

-

Knives:

-

4way(Optional 6 Ways)

-

Model:

-

Sl-215

Quick Details

-

Place of Origin:

-

Henan, China

-

Product name:

-

Firewood Processor

-

Color:

-

Customised

-

Application:

-

Cutting Forestry Wood Log Waste

-

Name:

-

Wood Chipper Chips Making Machine

-

Power:

-

55kw

-

Usage:

-

Wood Shredder Cutting Wood Branch

-

Raw material:

-

Waste Wood

-

Feature:

-

High Efficiency

-

Knives:

-

4way(Optional 6 Ways)

-

Model:

-

Sl-215

Shuliy 12 inch waste wood drum wood chipper machine for sale diesel engine

Brief Introduction of drum chipper

This drum chipper is a type of chipper that can handle a variety of woods.It is widely used in furniture factories, wood processing plants, etc. This wood chipper can deal with wood diameter of 23 cm or less, the finished product is about 3 cm, and the minimum processing capacity can reach 8 tons per hour. The drum chipper is divided into three sections: the feeding system, the working chamber, and the discharging system. Both the feeding system and the discharging system can be customized according to the customer's needs.

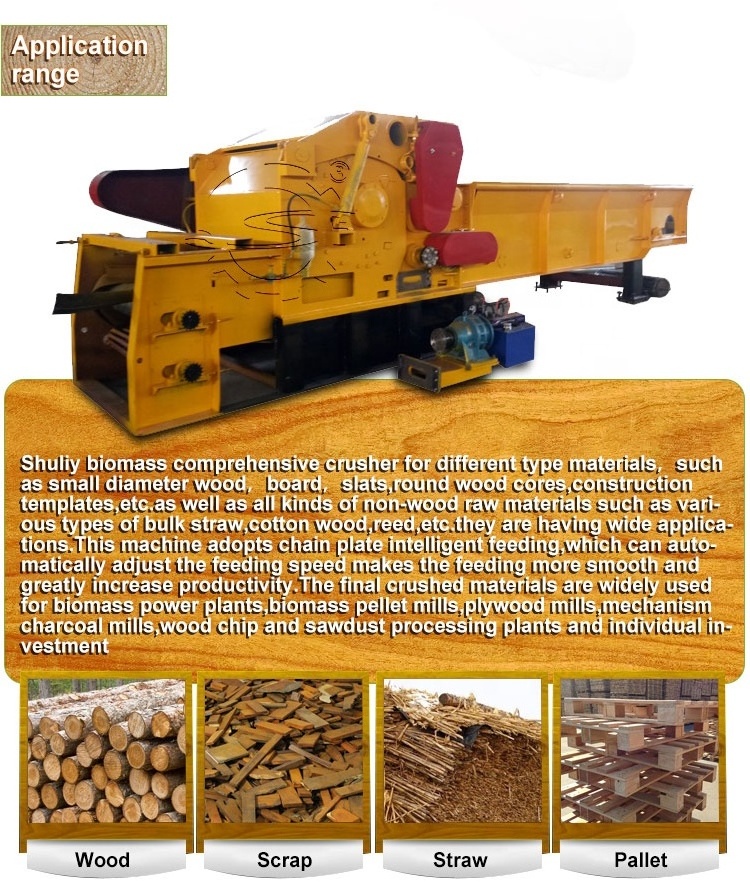

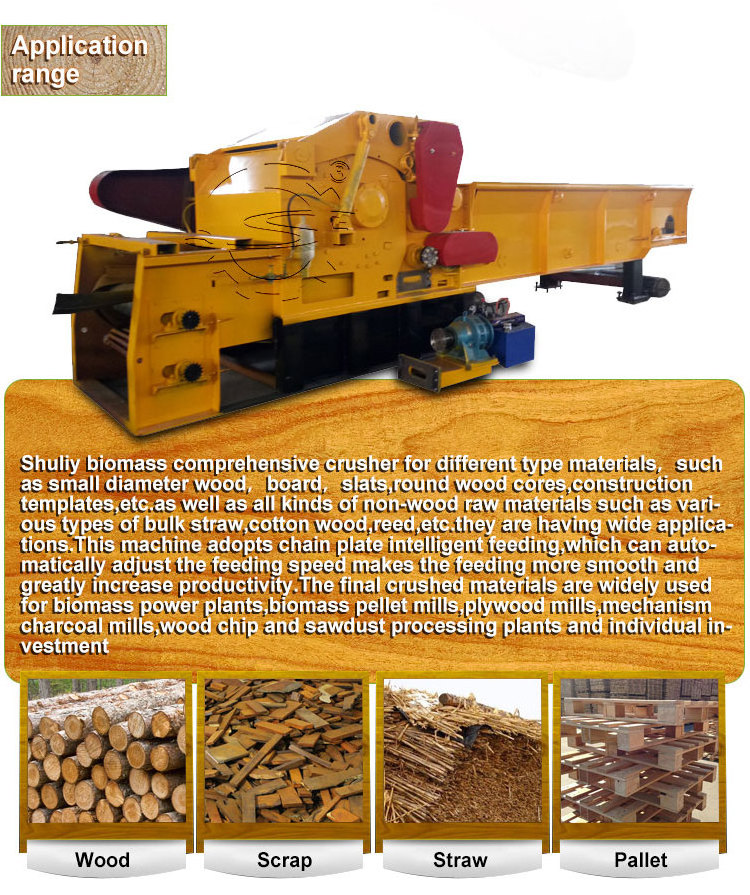

Application of drum chipper

Drum chipper making machine can be used for logs, pallets,tree,small-diameter wood, wood harvesting residues (branches, etc.), wood processing residues (slats, slabs, bark, wood trim, etc.), bamboo, cotton stalks, Non-wood fiber stems such as reed, rice straw, wheat straw, etc.The finished product is used as a basic raw material for the production of particleboard, medium and high density fiberboard, and pulp paper.

Advantage of drum chipper

1. Large output, the smallest capacity of drum chipper can reach 10t/h.

2. Wide uses range.Our drum chipper can handle variety materials,like logs and pallets.

3. Drum chipper adopts hydraulic transmission system, and there will be no blockage when feeding.

4. The size of finished product is adjustable, customers can adjust the finished product size according to his needs.

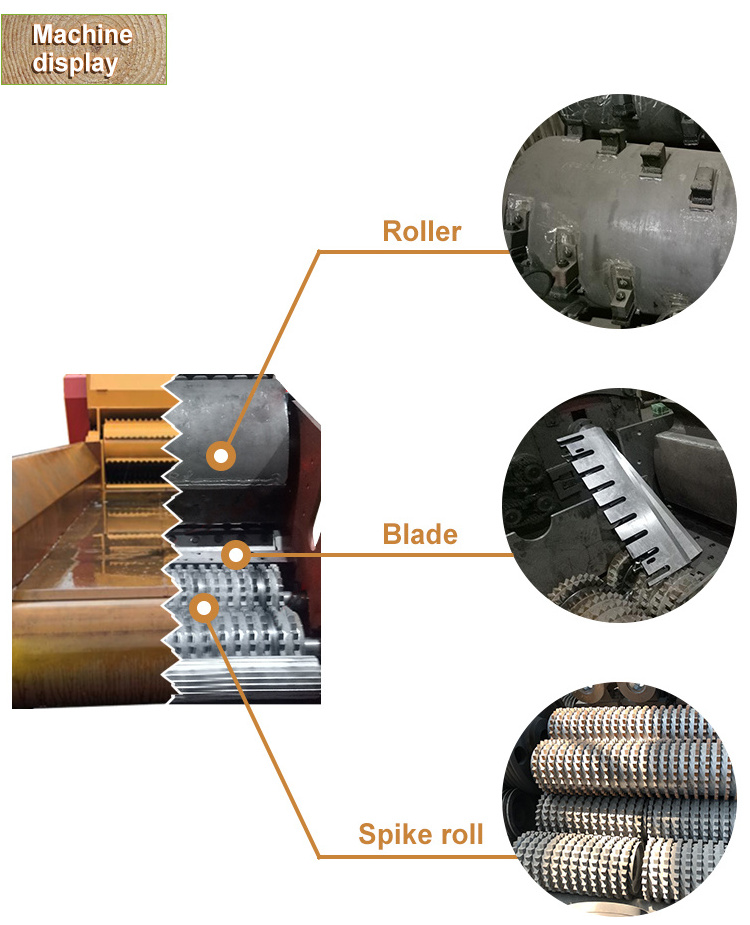

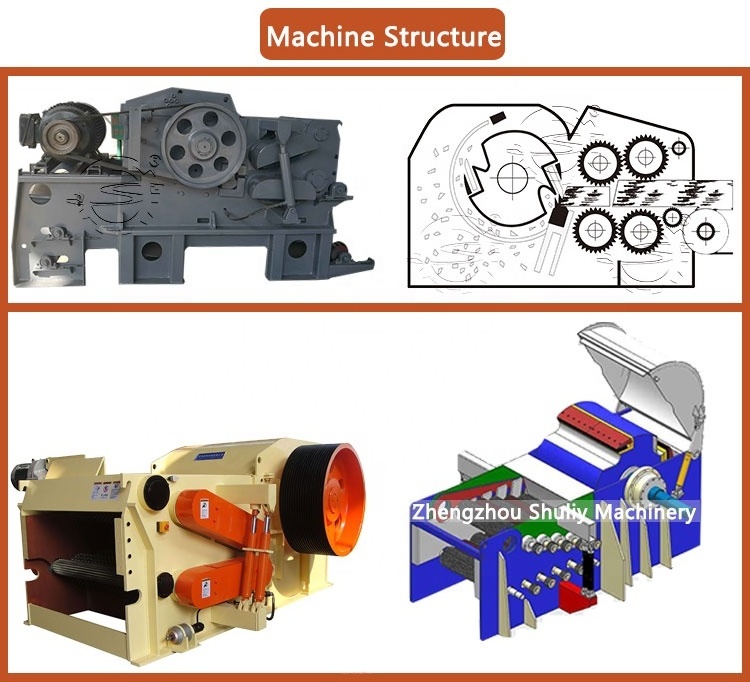

Work Principle of drum chipper

The wood chipper is made by high-quality steel.The whole machine is mainly composed of the feeding system, the knife roll, the upper and lower feeding rolls, the conveyor belt and the hydraulic system.The knife roll of the drum chipper is equipped with two or three or four knives, and the knives are fixed on the knife roll by a pressure block. Depending on the thickness of the material being cut, the upper feed roller assembly can be floated up and down within range by means of a hydraulic system.The cut piece of qualified material falls through the mesh hole,discharged from the bottom,the large piece of material still be cutted in the machine.

Parameter of drum chipper

| Model | SL-216 | SL-217 | SL-218 |

| Capacity | 5-8 T/H | 8-10 T/H | 10-12 T/H |

| Max process diameter | 160 MM | 230 MM | 300 MM |

| Motor | 45 KW | 55 KW | 90 KW |

| Weight | 3500 KG | 5600 KG | 8600 KG |

| Dimension | 1470*1550*970 MM | 2735*2200*1200 MM | 3105*2300*1650 MM |