- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

440V/380V/220V/50HZ

-

Weight:

-

13520 KG

-

Dimension(L*W*H):

-

70*45*135cm

-

Core Components:

-

Rectification Column

-

Product name:

-

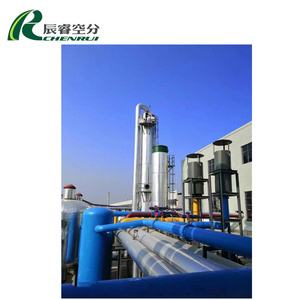

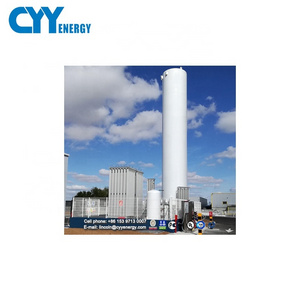

Cryogenic Air Separation Unit

-

Type:

-

Skid Mounted

-

Application:

-

Hospital Oxygen Generator

-

Technology:

-

Cryogenic ASU Technological Process

-

Capacity:

-

50-3000Nm3/h

-

Purity:

-

99.6%-99.9999%

-

Keyword:

-

Oxygen Nitrogen Argon Plant

-

Advantage:

-

Low Power Consumption

-

Feature:

-

Lower Space Demand

-

MOQ:

-

1 Set

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Longer

-

Production Rate:

-

100%

-

Voltage:

-

440V/380V/220V/50HZ

-

Weight:

-

13520 KG

-

Dimension(L*W*H):

-

70*45*135cm

-

Core Components:

-

Rectification Column

-

Product name:

-

Cryogenic Air Separation Unit

-

Type:

-

Skid Mounted

-

Application:

-

Hospital Oxygen Generator

-

Technology:

-

Cryogenic ASU Technological Process

-

Capacity:

-

50-3000Nm3/h

-

Purity:

-

99.6%-99.9999%

-

Keyword:

-

Oxygen Nitrogen Argon Plant

-

Advantage:

-

Low Power Consumption

-

Feature:

-

Lower Space Demand

-

MOQ:

-

1 Set

Pruduct Parameters

Our Product Feature

(1)Overall skid mounted direct structure、High pressure hose connection,the user needn’t invest the connecting pipe and valves.

(2)Produce high quality medical oxygen, completely accord with standard of medical oxygen, can sell to the hospital, can also for industrial use.

(3)The whole equipment without base installation, stable running, simple operation, easy maintenance.

|

Oxygen Output

|

Oxygen purity

|

Power

|

Operation pressure

|

|

100L

|

≥99.6%

|

380V/220V/50HZ/customized

|

1.2Mpa

|

1.Main air compressor

Air compressor is manufactured by world famous brand with Flexible and convenient operationstable operation and low energy consumption.

Air compressor is manufactured by world famous brand with Flexible and convenient operationstable operation and low energy consumption.

2. Air pre-cooling system

(1) Freon/air heat exchanging pre-cooling system, the unit is stable and very easy to maintain, high & low pressure and overheat self-protection function to make sure the operation is safer and more reliable.

(2) Skid closed structure with little area occupation

3.Air purification system

(1) Remove dangerous impurities contained in the air before entering the cold box and brings complete safety for a long operating time without any necessary defrosting

(2) Use double layer system, very effectively protects the layer of the molecular sieve.

(3) High strength, large dynamic adsorption capacity, long service life.

4. Turbine expansion unit

Adopt advanced design and processing software to achieve the best performance

(1) Freon/air heat exchanging pre-cooling system, the unit is stable and very easy to maintain, high & low pressure and overheat self-protection function to make sure the operation is safer and more reliable.

(2) Skid closed structure with little area occupation

3.Air purification system

(1) Remove dangerous impurities contained in the air before entering the cold box and brings complete safety for a long operating time without any necessary defrosting

(2) Use double layer system, very effectively protects the layer of the molecular sieve.

(3) High strength, large dynamic adsorption capacity, long service life.

4. Turbine expansion unit

Adopt advanced design and processing software to achieve the best performance

Product Overview

Please send your inquiry details in the below,

click "Send" now

|

NO

|

Main Part

|

Function

|

|

1

|

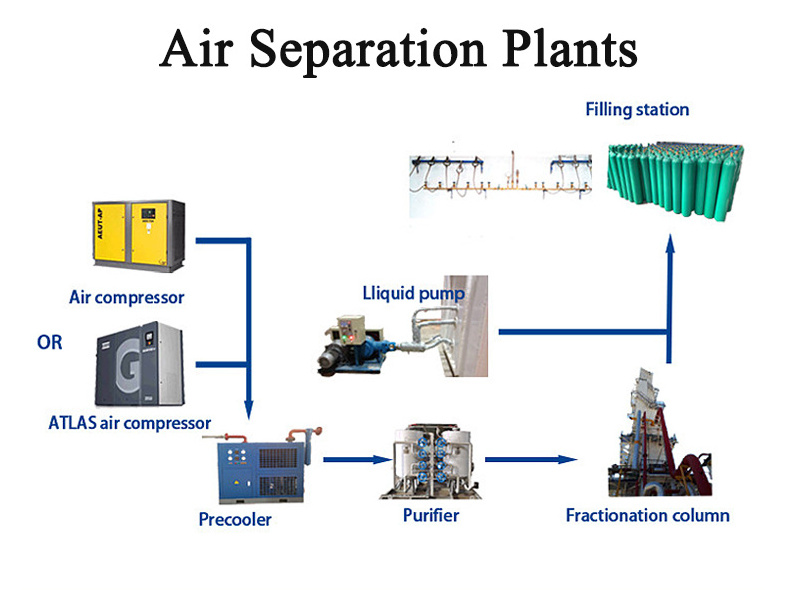

Air Compressor

|

The air compressor is sprayed-oil screw type compressor, box-body construction and main machine is imported from Germany. It has low noise and the main machine combines gas, lubrication, water, cooling and electrical instrument to one compact unit. The control system adopts PLC controller, touch-way panel provides the operation of all adjustment of parameter and critical running parameter. The liquid crystal display (with English text) has full protection function and thus has minimal operation supervision from a plant operator.

|

|

2

|

Pre Cooling System

|

It adopts a full-close imported compressor therefore refrigeration agent will never leak out. The high-efficient steam water separator and imported automatic drain water machine will ensure the outlet will not produce condensation. Refrigeration component

is imported to support plant can run continuously (non stop) for 365 days a year. It is equipped with long-distance signal connecting point of air inlet temperature, long distance signal of start and stop machine and operating trouble indicator or signal thus it is convenient for user’s interlock supervision. The unit is box type body construction. The foundation is easy to install and construct. |

|

3

|

Purifier

|

The unit is composed of two vessels: one is on heating while the other being regenerated. This ensures that the gas will be clean and purified to prolong the running period of rectifying (rectification) column. The system uses nitrogen to heat for regenerated and has automatic control for the temperature heat.

|

|

4

|

Turbine Expander

|

Turbine expander has the following advantages:

1.easy to install

2.less maintenance and easy to maintain

3.high efficient, runs and operate stable

4.has minimal cooling lost

5.Rectification Column

|

|

5

|

Rectification Column

|

It incorporates an aluminum fin type heat exchange. The aluminum increases the heat exchange’s affection and depresses the operation pressure. This process will produce less power consumption thus saving on electricity cost. The unit is equipped with an

advanced digital instrument for the temperature, flow and liquid display. It has replaced the traditional meters. |

Reviews

Successful case

Our Advantage

Hot Searches