- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110-480V

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

100 KG

-

Name:

-

round vibrating sieve

-

Keyword:

-

vibrating sieve shaker

-

Machine type:

-

Continous Working

-

Layer:

-

1-5 layers

-

Mesh clean:

-

Ultrosonic Device/bouncing ball

-

Driving force:

-

Electricity

-

Motor:

-

Vertical Vibrating Motor

-

Installation:

-

Engineer guidance

-

Capacity:

-

1-2Tons/h

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Colorado, United States

-

Brand Name:

-

Tesheng

-

Voltage:

-

110-480V

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

100 KG

-

Name:

-

round vibrating sieve

-

Keyword:

-

vibrating sieve shaker

-

Machine type:

-

Continous Working

-

Layer:

-

1-5 layers

-

Mesh clean:

-

Ultrosonic Device/bouncing ball

-

Driving force:

-

Electricity

-

Motor:

-

Vertical Vibrating Motor

-

Installation:

-

Engineer guidance

-

Capacity:

-

1-2Tons/h

Product Description

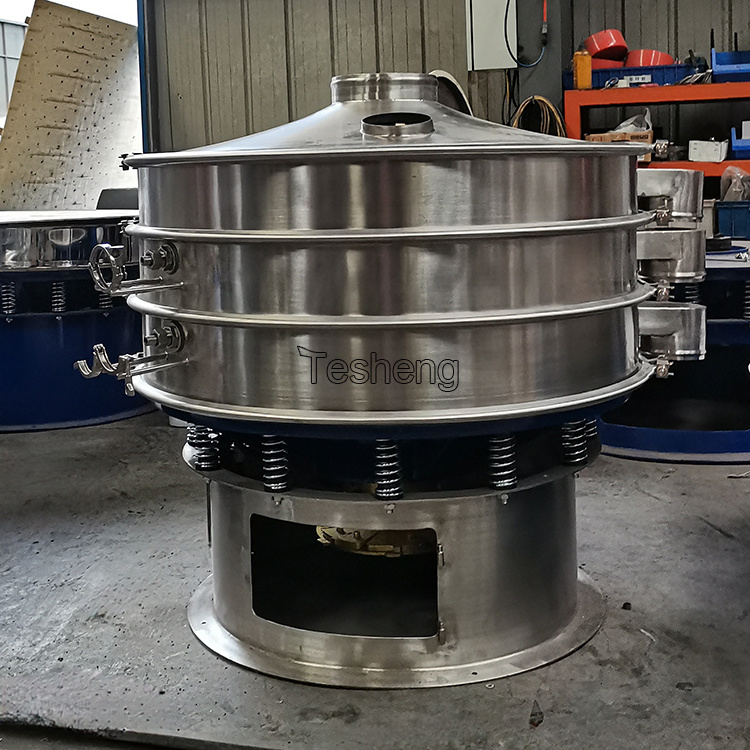

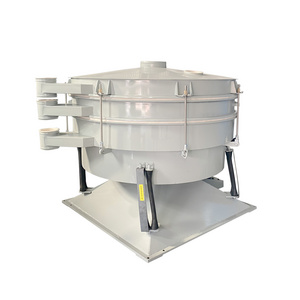

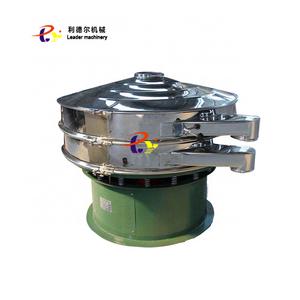

YS series types round vibrating sieve shaker vibrating machine

powder sieving machine factory

Round vibrating sieve

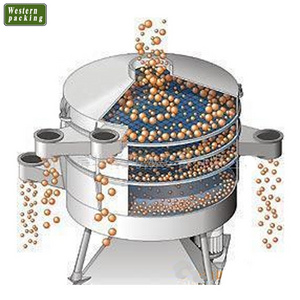

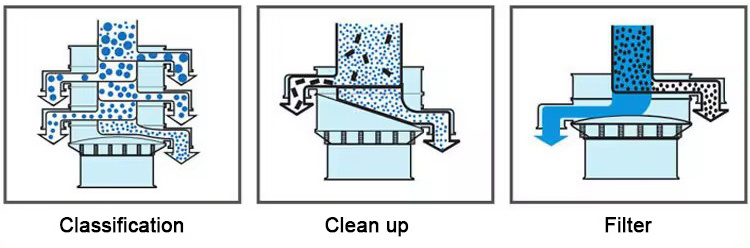

is a commonly used screening equipment used for classifying and filtering powder, granular and slurry materials. It uses rotational vibration to quickly separate materials on the screen through centrifugal force and vibration force to achieve stratified classification of materials with different particle sizes.

Round vibrating sieve

s have efficient and precise screening effects and are widely used in chemical, food, mining and other industries to improve production efficiency and product quality. It also has the flexibility to adjust the amplitude and screening accuracy to adapt to the processing requirements of different materials.

Features and advantages of

Round vibrating sieve

1. Efficient screening: It can handle large amounts of materials and separate particles of different sizes quickly and accurately.

2. Precise screening: The

Round vibrating sieve

has excellent screening accuracy and can achieve high-precision grading and classification.

3. Large processing capacity:

Round vibrating sieve

s usually have large processing capacity and are suitable for high-volume production lines.

4. Multi-layer screening:

Round vibrating sieve

s often have a multi-layer screen structure and can screen multiple particle sizes at the same time.

|

Model

|

YS-600

|

YS-800

|

YS-1000

|

YS-1200

|

YS-1500

|

YS-1800

|

YS-2000

|

||||||

|

Diameter (mm)

|

Φ600

|

Φ800

|

Φ1000

|

Φ1200

|

Φ1500

|

Φ1800

|

Φ2000

|

||||||

|

Screen area

(m) |

0.24 |

0.45 |

0.67 |

1.0 |

1.6 |

2.43 |

3.01 |

||||||

|

Screen size

(Mesh number) |

2-500 |

|

|

|

|

|

|

||||||

|

Feed particle

size (mm) |

<Φ10 |

<Φ15 |

<Φ20 |

<Φ30 |

|

|

|

||||||

|

Frequency of

vibration (rpm) |

1500 |

1500 |

1500 |

1500 |

1500 |

1500 |

1500 |

||||||

|

Effective screen

area diameter (mm)

|

Φ560 |

Φ760 |

Φ930 |

Φ1130 |

Φ1430 |

Φ1760 |

Φ1960 |

||||||

|

Layer

|

1-5

|

|

|

|

|

|

|

||||||

|

Power (Kw)

|

0.25

|

0.55

|

0.75

|

1.1

|

1.5

|

2.2

|

3

|

||||||

The picture below shows our screening, mixing and storage line designed for a customer in Indonesia. Production process: The material is sent to the sieve machine by the conveying equipment, and the mixer machine mixes the sifted material and finally stores it in the hopper.

If you also need drawings, please contact us today!

Details Images

Application

Hot Searches