- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

10000

-

Weight (KG):

-

500 KG

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KEDA Chemical machinery

-

Voltage:

-

380V

-

Power (kW):

-

4 kW

-

Product name:

-

Powder Mixer

-

Name:

-

Ribbon Blender

-

Function:

-

Mixer Blender

-

Usage:

-

Mixing Powder Proucts

-

Machine Type:

-

Industiral Blender Mixer Machine

-

Heating method:

-

Electric Heating

-

Keyword:

-

Powder Blender

-

After-sales Service Provided:

-

Free Spare Parts

-

Application scope:

-

Chemical Cosmetic Food

Quick Details

-

Barrel Volume (L):

-

1000

-

Max. Loading Volume (L):

-

600 L

-

Range of Spindle Speed(r.p.m):

-

1 - 40 r.p.m

-

Max. Loading Capacity:

-

10000

-

Weight (KG):

-

500 KG

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KEDA Chemical machinery

-

Voltage:

-

380V

-

Power (kW):

-

4 kW

-

Product name:

-

Powder Mixer

-

Name:

-

Ribbon Blender

-

Function:

-

Mixer Blender

-

Usage:

-

Mixing Powder Proucts

-

Machine Type:

-

Industiral Blender Mixer Machine

-

Heating method:

-

Electric Heating

-

Keyword:

-

Powder Blender

-

After-sales Service Provided:

-

Free Spare Parts

-

Application scope:

-

Chemical Cosmetic Food

Product Description

Horizontal ribbon mixer is the introduction of foreign advanced technology, the factory professional and technical personnel to digest the innovative design results, is a new type of efficient mixing equipment.

The internal barrel surface is smoothed by polishing and equipped with center shaft and double S-shaped paddle. Mixing materials process is fast and homogeneous, which can be finished within 5-10 minutes for each batch. Mixture of special materials need to be confirmed by users.

Horizontal ribbon blender#mixer washing powder mixing machine ribbon mixer.

ribbon blender#mixer washing powder mixing machine ribbon mixer

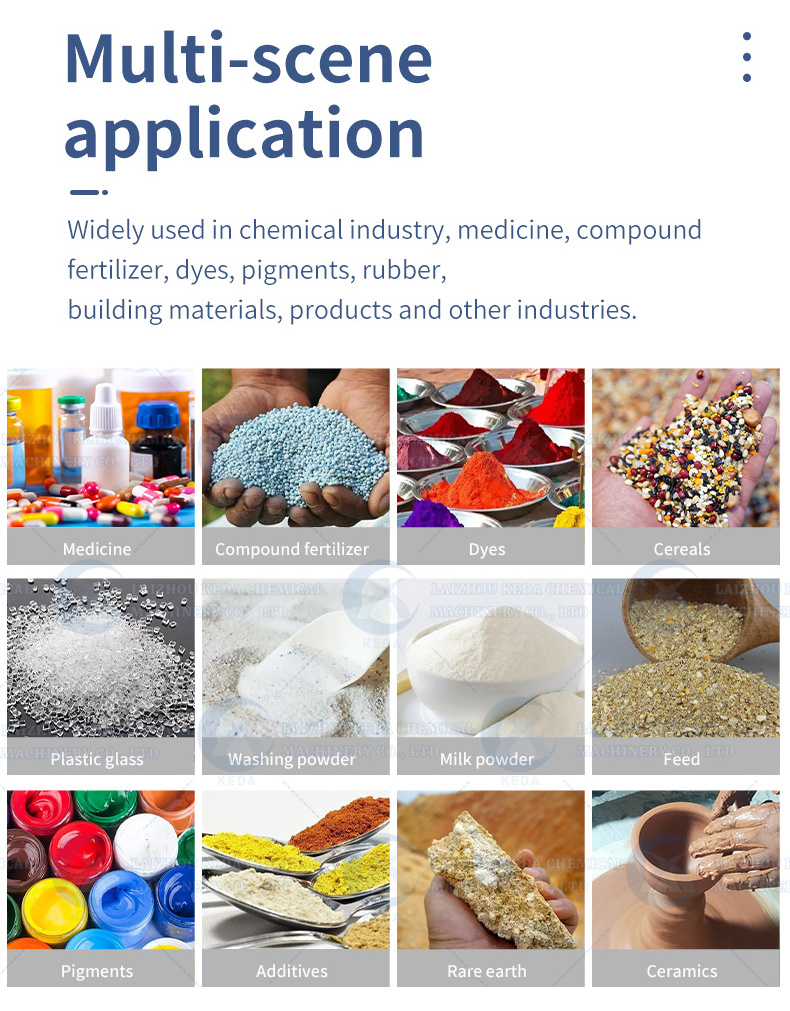

Using Range

Widely used in chemical industry, compound fertilizer, dyes, pigments, rubber, building materials, food, milk powder, health products, feed, additives,aquaculture, biological engineering, fine chemical industry, ceramics, refractory materials, rare earth, plastic glass, new materials, nuclear materials and other industries . Horizontal ribbon blender#mixer washing powder mixing machine 2 ton ribbon mixer

Widely used in chemical industry, compound fertilizer, dyes, pigments, rubber, building materials, food, milk powder, health products, feed, additives,aquaculture, biological engineering, fine chemical industry, ceramics, refractory materials, rare earth, plastic glass, new materials, nuclear materials and other industries . Horizontal ribbon blender#mixer washing powder mixing machine 2 ton ribbon mixer

Main Features

1) Horizontal tank body, need small space but more capacity.

1) Horizontal tank body, need small space but more capacity.

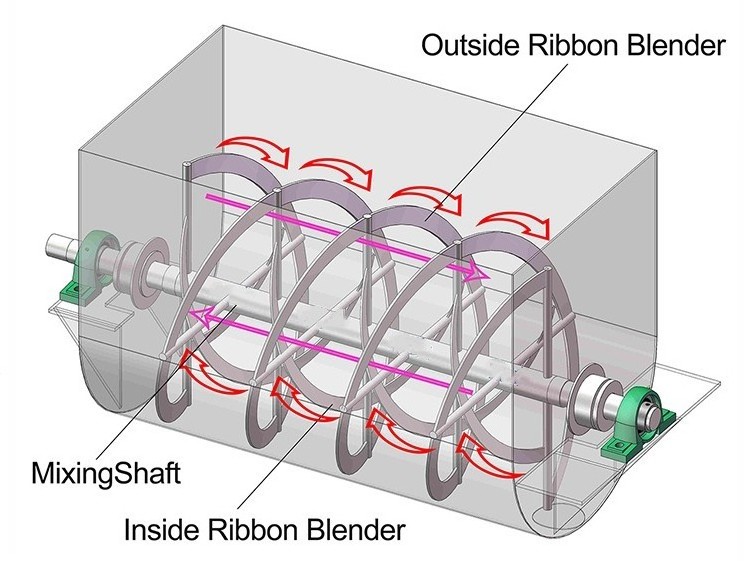

2) Dual screw structure-The inner screw push the material form central to sides and the outer screw push the material from sides to the center to make the material effective mixing.

3) Gear box drive the auger shaft , low noise and low malfunction, long using life.

4) U-Shape tank bottom, better for material discharge and cleaning.

5) Pneumatic cylinder to control the discharge exit.

dry powder ribbon mixer horizontal ribbon mixer ribbon mixer

6) Air cylinder help the top cover easy open.

dry powder ribbon mixer horizontal ribbon mixer ribbon mixer with heating

7) Heating,cooling function can be realized.

dry powder ribbon mixer horizontal ribbon mixer ribbon mixer with heating

8) Customized ribbon blender available.

dry powder ribbon mixer horizontal ribbon mixer ribbon mixer with heating

9) PLC controlled, equipped with weigh modular.

Ribbon auger mixer detergent powder horizontal ribbon mixer dry

Specifications Configuration

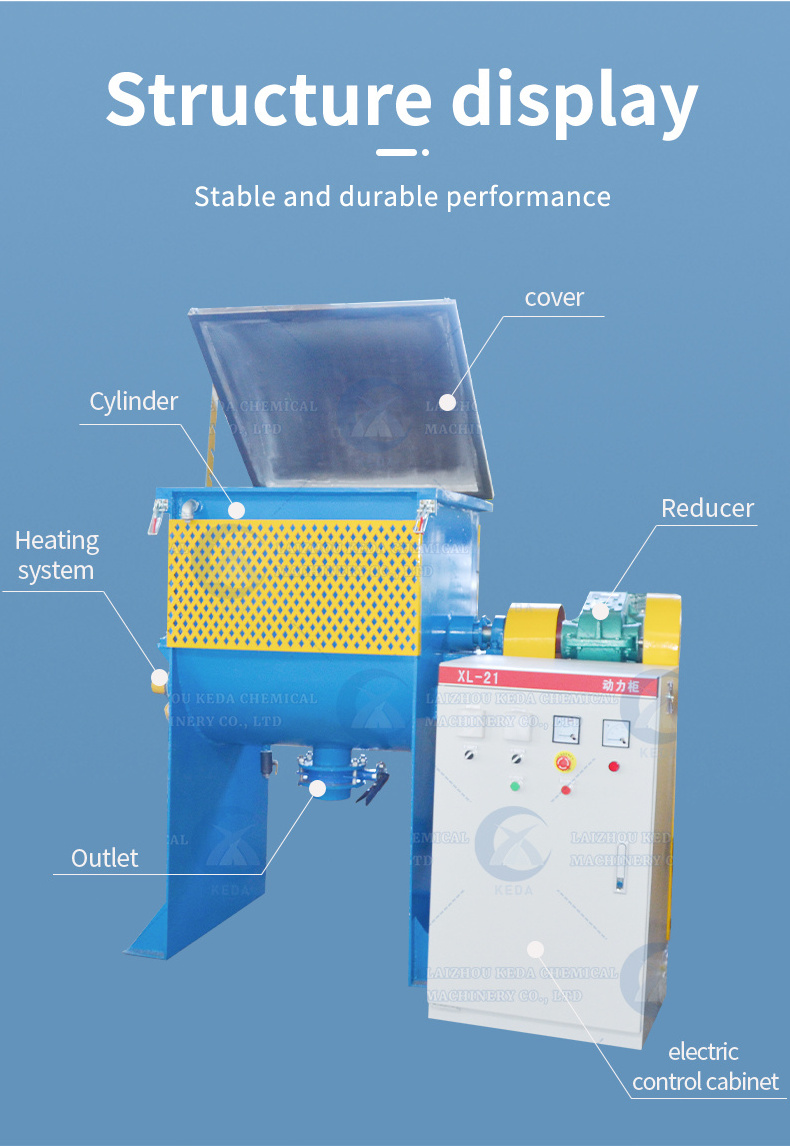

1) Major sections: barrel, ribbon agitators, feeding parts, discharging part and driven unit

1) Major sections: barrel, ribbon agitators, feeding parts, discharging part and driven unit

2) Sizes: available from 200L to 10000L.

Ribbon auger mixer detergent powder horizontal ribbon mixer

3) Material: Carbon Steel, Stainless Steel 201,304, 316L.

4) Discharge: Flap valve, butterfly valve, slide gate valve, ball valve, manually or pneumatically.

5) Speed:Constant speed rotation,also controls such as variable frequency drives, motor starters and operator stations are available.

6)Temperature: mixer can be equipped with heating or cooling jacket if temperature control is required

7)Spray :nozzles for liquid introduction. dry powder ribbon mixer horizontal ribbon mixer ribbon mixer

8)Open cover: pneumatic, manual. Horizontal ribbon blender#mixer washing powder mixing machine

4) Discharge: Flap valve, butterfly valve, slide gate valve, ball valve, manually or pneumatically.

5) Speed:Constant speed rotation,also controls such as variable frequency drives, motor starters and operator stations are available.

6)Temperature: mixer can be equipped with heating or cooling jacket if temperature control is required

7)Spray :nozzles for liquid introduction. dry powder ribbon mixer horizontal ribbon mixer ribbon mixer

8)Open cover: pneumatic, manual. Horizontal ribbon blender#mixer washing powder mixing machine

Product Paramenters

|

Model

|

500L

|

1000L

|

2000L

|

4000L

|

6000L

|

8000L

|

|||||

|

Volume / L

|

500

|

1000

|

2000

|

4000

|

6000

|

8000

|

|||||

|

Motor Power / KW

|

5.5

|

7.5

|

15

|

22

|

37

|

45

|

|||||

|

Speed / r/m

|

41

|

33

|

33

|

27

|

27

|

23

|

|||||

|

Dimension / m

|

1.9*0.7.1.4

|

3*0.8*1.5

|

3.3*1.4*1.7

|

3.6*1.4*1.7

|

3.8*1.7*1.8

|

4.5*1.8*1.9

|

|||||

|

PlateThickness /mm

|

4

|

4

|

6

|

8

|

8

|

8

|

|||||

|

Material

|

Contact material SUS 304, other material carbon steel. SUS201, 316 is available

|

|

|

|

|

|

|||||

Detailed Images

Horizontal Ribbon Mixer Heating Function

Ribbon mixer heating type is made of double U barrel. The inner wall is all stainless steel. Heat conducting oil or water is used as heating medium. The temperature standard is 50-150 degrees, the highest can reach 300 degrees. The heat is uniform and convenient to control.

Dry powder ribbon mixer machine electric charcoal powder detergent powder mixer blender. Dry powder ribbon mixer machine electric charcoal powder detergent powder mixer blender washing powder

Dual screw structure

Stainless steel or carbon steel material.

The inner screw push the material form central to sides and the outer screw push the material from sides to the center to make the material effective mixing.

Brand motor

The motor and reducer of famous factory are selected ,and the strength.

Bearing

Gland packings, a

void dust infiltration,all stainless steel durable

Outlet

The manual or pneumatic discharge port can be made, according to the requirements of the customer

Electric heating

mixer can be equipped with heating or cooling jacket if temperature control is required

Related Products

Company Introduction

Customer Reviews

Certifications

Our Service

Hot Searches