1) Un-power; manual de-coiler; max. Capacity: 5000kg

2) Suit for coil inner-diameter: 650mm

3) Manual power expands the coil inner surface.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Hener

-

Voltage:

-

as customers' requirement

-

Power:

-

11.5 KW

-

Weight:

-

4800 kg

-

Product name:

-

door frame machine

-

After-sales Service Provided:

-

After-sales Service

-

Usage:

-

Construction Building Material

-

Material:

-

GI PPGI GL PPGL

-

Application:

-

Building door

-

Cutting type:

-

Hydraulic Cutting

-

Operation:

-

automatic

-

Plc:

-

Delta

-

Roller material:

-

45# Forged Steel

-

Shaft material:

-

45# Steel Diameter 60mm Shaft

Quick Details

-

Marketing Type:

-

Hot Product 2024

-

Production Capacity:

-

30sets/month

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Hener

-

Voltage:

-

as customers' requirement

-

Power:

-

11.5 KW

-

Weight:

-

4800 kg

-

Product name:

-

door frame machine

-

After-sales Service Provided:

-

After-sales Service

-

Usage:

-

Construction Building Material

-

Material:

-

GI PPGI GL PPGL

-

Application:

-

Building door

-

Cutting type:

-

Hydraulic Cutting

-

Operation:

-

automatic

-

Plc:

-

Delta

-

Roller material:

-

45# Forged Steel

-

Shaft material:

-

45# Steel Diameter 60mm Shaft

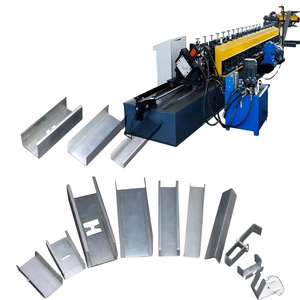

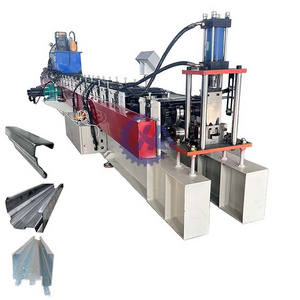

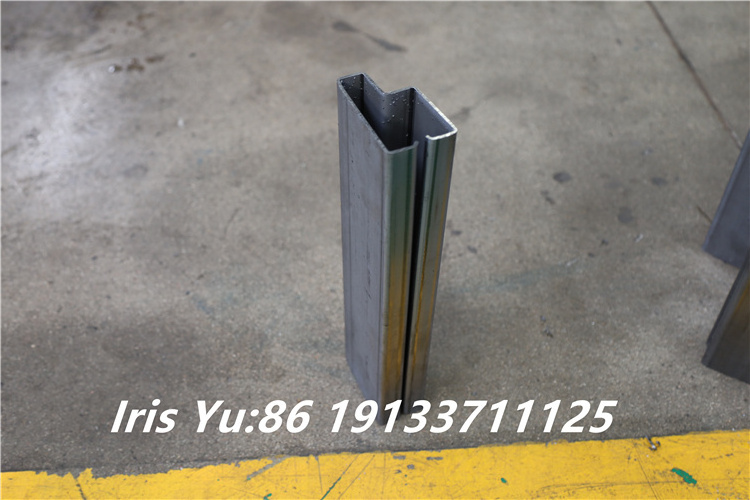

Product Display

This door frame roll forming machine is for steel or aluminum sheet cold form industries. It can form door frame profiles according to customer’s requirement continuously, automatically cut to length. The equipment adopts PLC control, AC frequency and adjusting the speed technology, and it realizes the continuous automatically production. Therefore, it is really a new type of energy-saving and high-effective equipment for metal door frame. And it has many advantages, just like high forming speed, low noise, stable transmission, easy operation, good appearance and so on.

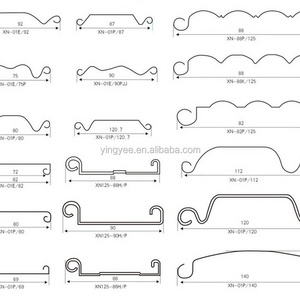

Here are some popular drawing for your reference

Specifications

|

Material Type

|

|

Pre-painted steel coil & galvanized coils

|

Pre-painted steel coil & galvanized coils

|

|

|||

|

Thickness

|

|

0.3-0.8mm

|

0.3-0.8mm

|

|

|||

|

Yield strength

|

|

235Mpa.Q345Mpa, Q550Mpa

|

235Mpa.Q345Mpa, Q550Mpa

|

|

|||

|

Roller material

|

|

Quenched and tempered treatment, hard chrome coated.05-0.07mm

|

Quenched and tempered treatment, hard chrome coated.05-0.07mm

|

|

|||

|

Forming speed

|

|

About 15-20m/min

|

About 15-20m/min

|

|

|||

|

Speed adjusting mode

|

|

About 15-20m/min

|

AC Frequency

|

|

|||

|

Roller drive

|

|

Decelerating motor + Chain drive

|

Decelerating motor + Chain drive

|

|

|||

|

Cutting mode

|

|

Hydraulic cutting

|

Hydraulic cutting

|

|

|||

|

Cutter material

|

|

Cr12 mould steel

|

Cr12 mould steel

|

|

|||

|

Length measurement

|

|

Encoder

|

Encoder

|

|

|||

|

Control mode

|

|

Panasonic or Delta PLC

|

Panasonic or Delta PLC

|

|

|||

|

Main motor

|

|

5.5KW

|

5.5KW

|

|

|||

|

Hydraulic station motor

|

|

4KW

|

4KW

|

|

|||

Product Paramenters

1. Manual de-coiler:

2. Roll-Forming M/C:

* The main frame of machine is welded separately and the outside wall is connected by screw after being roto blasted on the

surface.

* Roller Material is high grade No.45 forged steel, with digital-controlled procession.

* Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product.

* The rollers are plated with hard chrome with thickness of 0.05mm on the surface after being machined by the exact machine tool.

So that ensures long life of forming rollers.

surface.

* Roller Material is high grade No.45 forged steel, with digital-controlled procession.

* Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product.

* The rollers are plated with hard chrome with thickness of 0.05mm on the surface after being machined by the exact machine tool.

So that ensures long life of forming rollers.

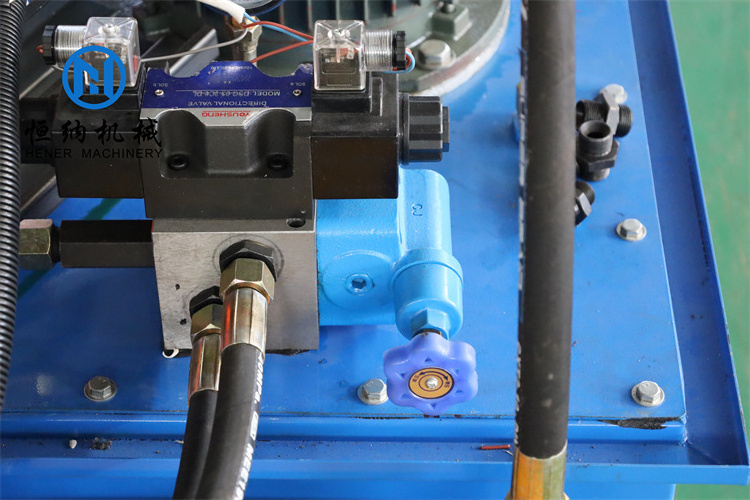

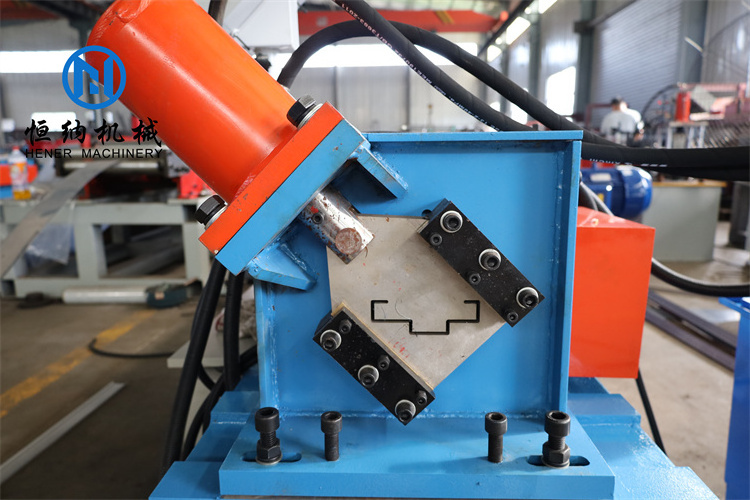

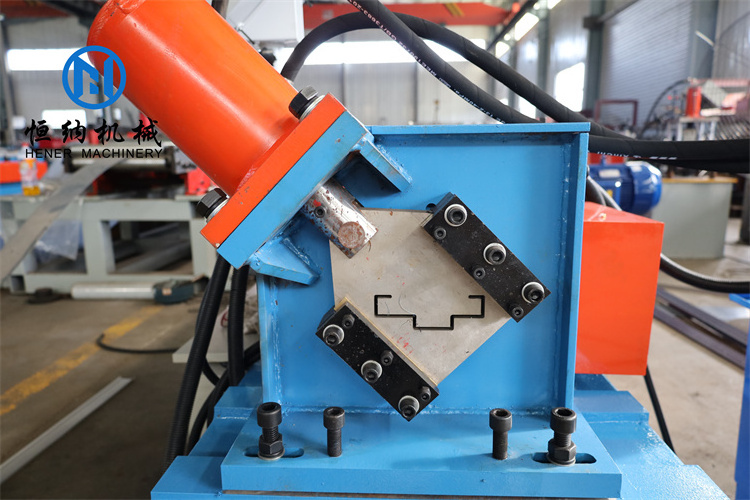

3. Hydraulic Post Cutting

1) Adopts post cutting, Stop when cutting;

2) The cutting blade material is Cr12 with quenched treatment.

2) Adopts welded frame for good rigidity.

4) Cutting frame has been heat treatment to avoid final product deformation. cutting length tolerance ±2mm;

2) The cutting blade material is Cr12 with quenched treatment.

2) Adopts welded frame for good rigidity.

4) Cutting frame has been heat treatment to avoid final product deformation. cutting length tolerance ±2mm;

4. Hydraulic station:

1) It supplies the power for the hydraulic cutter.

2) All hydraulic accessories are all use Chinese or importing famous brand products.

2) All hydraulic accessories are all use Chinese or importing famous brand products.

5. Profile Stack:

1) It supplies the power for the hydraulic cutter.

2) All hydraulic accessories are all use Chinese or importing famous brand products.

2) All hydraulic accessories are all use Chinese or importing famous brand products.

Hot Searches