- Product Details

- {{item.text}}

Quick Details

-

Theoretical Shot Volume(cm³):

-

55 cm³

-

Injection Rate (g/s):

-

45 g/s

-

Injection Weight (g):

-

128 g

-

Screw Speed (rpm):

-

0 - 150 rpm

-

Screw diameter (mm):

-

28 mm

-

Distance between Tie Bars:

-

450*250

-

Weight (KG):

-

650 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

330 mm

-

Model Number:

-

DLB-200-p

-

Brand Name:

-

Plastar

-

Power (kW):

-

3.75 kW

-

Plastic Type:

-

Thermoplastic

-

Product name:

-

Plastic Injection Moulding Machine

-

Name:

-

Vertical Plastic Injection Molding Machine

-

Color:

-

Blue

-

Function:

-

Plstic Injection Molding Machinery

-

Injection pressure:

-

1004kgf/cm3

-

Used for:

-

Plasic Products

-

Product:

-

PP PVC ABS TPE

-

Application:

-

Inserting Plastic Products

Quick Details

-

Mold Height(mm):

-

40 - 200 mm

-

Ejector Stroke(mm):

-

28 mm

-

Ejector Force(kN):

-

18 kN

-

Theoretical Shot Volume(cm³):

-

55 cm³

-

Injection Rate (g/s):

-

45 g/s

-

Injection Weight (g):

-

128 g

-

Screw Speed (rpm):

-

0 - 150 rpm

-

Screw diameter (mm):

-

28 mm

-

Distance between Tie Bars:

-

450*250

-

Weight (KG):

-

650 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

330 mm

-

Model Number:

-

DLB-200-p

-

Brand Name:

-

Plastar

-

Power (kW):

-

3.75 kW

-

Plastic Type:

-

Thermoplastic

-

Product name:

-

Plastic Injection Moulding Machine

-

Name:

-

Vertical Plastic Injection Molding Machine

-

Color:

-

Blue

-

Function:

-

Plstic Injection Molding Machinery

-

Injection pressure:

-

1004kgf/cm3

-

Used for:

-

Plasic Products

-

Product:

-

PP PVC ABS TPE

-

Application:

-

Inserting Plastic Products

Injection Molding Machine

DLB-200-P

Professional Injection Molding Machine Supplier,

Feature

Feature

1. Machine vertical lock mold/vertical to cast, is suitable the common electric appliance plug,the electronic components and so on small in lays to take shape.

2. sections the temperature control/projects the speed/back pressure and so on not to have the section

adjustment, suits components of the precise revert to take shape.

adjustment, suits components of the precise revert to take shape.

3.

The fast lock mold/low pressure idling speed closes the mold, locks the mold exceptionally when then automatic tight open the mold. This special safe design, and so on can get up the protective function to the mold.

4. The stamping die fixed/top die activity type, to takes shape inlays to have the very good

localization in the mold. The end product has the fluid capping to leave the installment, the end product takes out extremely facilitates easily.

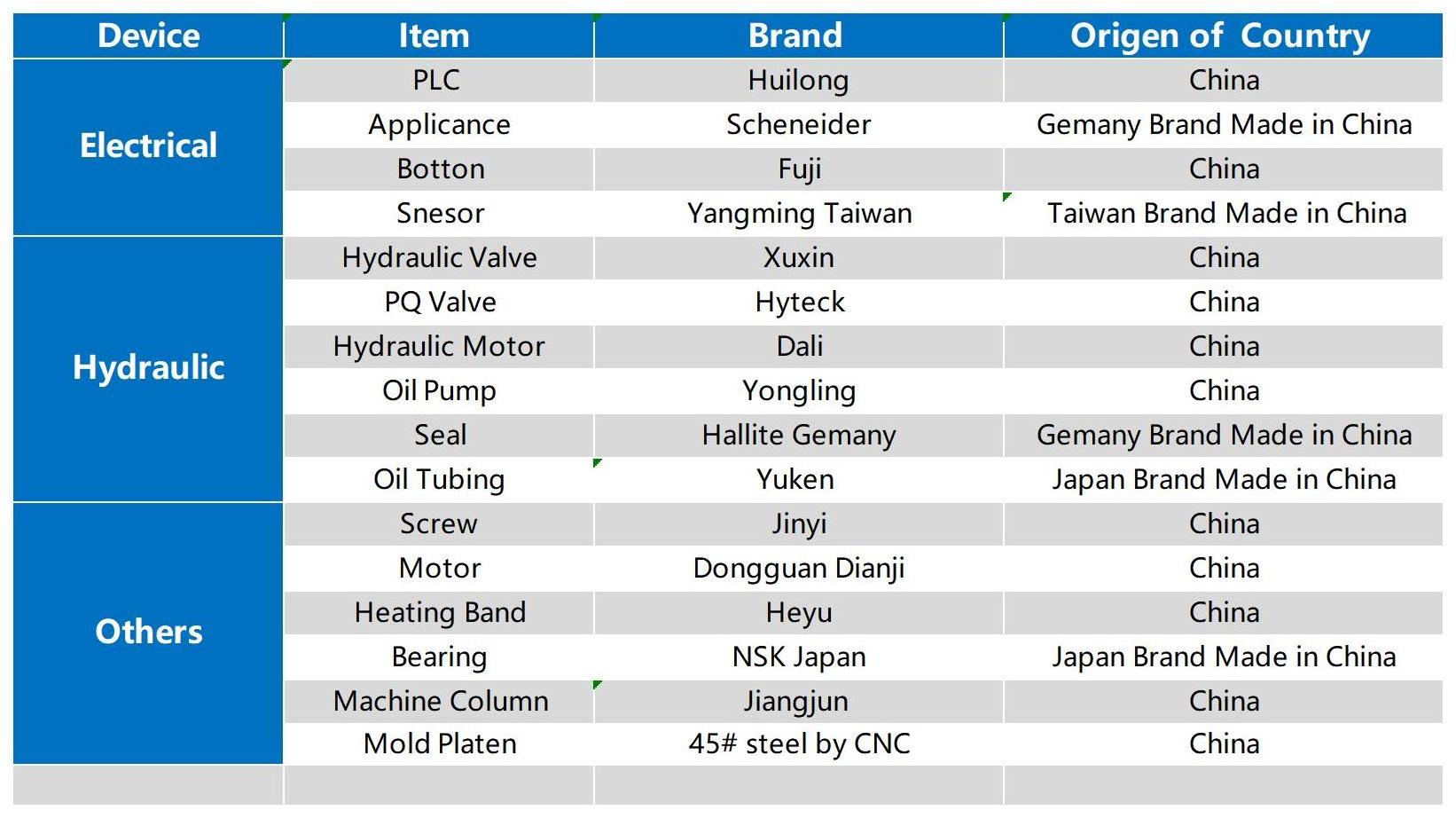

5. Electric control parts/hydraulic parts adopt domestic famous brand, precision and durable operation noise is

low. The clamping force is 15TON〜35TON, and can be controlled by single or double ratio computer.

low. The clamping force is 15TON〜35TON, and can be controlled by single or double ratio computer.

Main Specifications

1. Vertical mold closing and vertical injection, suitable for all insert molding.

2. The stepless adjustment of temperature control, firing rate, pressure and screw speed is suitable for the molding of various precision plastic parts.

3. The lower mold is fixed and the upper mold is movable, which has good positioning for the inserted items, and has a finished product ejection device .

4. Low pressure mold closing device protects mold safety.

5. The material tube can be lifted and lowered, the cleaning head is convenient, and it is easier to fix the mold.

6 Unique oil circuit design increases molding efficiency by more than 30%.

Components Brand

We use international famous brand component to control the better quality and some components also accept

customermation.

Compatible Equipment

Hot Searches