- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

in order

-

Weight (T):

-

3 T

-

Power (kW):

-

70

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

Max. 3000 Degree High Temperature Furnace For Lab And Industrial

-

Use:

-

Ultra-high temperature furnace

-

Max temperature:

-

3000C

-

Power(W):

-

15-300KW

-

Weight:

-

0.3 - 350T

-

Keyword:

-

Ultra-high temperature graphitization furnace

-

Furnace type:

-

IGBT furnace

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

LPMIE

-

Voltage:

-

Requirement

-

Dimension(L*W*H):

-

in order

-

Weight (T):

-

3 T

-

Power (kW):

-

70

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

Max. 3000 Degree High Temperature Furnace For Lab And Industrial

-

Use:

-

Ultra-high temperature furnace

-

Max temperature:

-

3000C

-

Power(W):

-

15-300KW

-

Weight:

-

0.3 - 350T

-

Keyword:

-

Ultra-high temperature graphitization furnace

-

Furnace type:

-

IGBT furnace

Max. 3000 Degree High Temperature Furnace For Lab And Industrial

Application:

S intering and graphitization of carbon materials, sintering of carbon fiber rope, high-temperature treatment of battery cathode materials, high-temperature treatment of graphite powder, carbonization of carbon fiber, and other high-temperature treatment of carbon materials.

Graphitization

W orking principle:

After three-phase full wave uncontrolled rectification and IGBT inverter technology, the three-phase power frequency AC from the power grid outputs medium frequency single-phase AC tens to hundreds of times higher than the power frequency from the inverter bridge to the load. The load of the device is an LC series oscillation circuit composed of induction coil (including heating workpiece) and medium frequency electrothermal capacitor.

F eatures:

1. IGBT Variable frequency power supply has high electrothermal conversion efficiency, economic and environmental protection, conversion efficiency of more than 95%, low loss, high stability and safety, and no interference to the power supply. It is a green and environmental protection power supply.

2. Ultra high temperature furnace body within 3000 ℃ can fully meet the sintering and graphitization of various materials.

4. The digital display intelligent temperature control system is adopted to complete the temperature measurement and control process with full-automatic and high precision. The system can raise the temperature according to the given temperature rise curve, and can store 20 40 different process heating curves in total.

4. Adopt internal circulation pure water cooling system; Digital flow monitoring system, furnace body conversion adopts high-performance medium frequency contactor; Comprehensive PLC water, electricity and gas automatic control and protection system.

Technical Parameter :

|

Model |

1.1L |

10L |

28L |

|

Volume(L) |

1.1 |

10 |

28 |

|

Maximum temperature( ℃ ) |

3000 |

3000 |

3000 |

|

Rated temperature( ℃ ) |

2800 |

2800 |

2800 |

|

Effective heating zone(mm) |

Φ1 00*150mm |

Φ 200*300mm |

Φ3 00*400mm |

|

Power(KW) |

30 |

70 |

80 |

|

Frequency(HZ) |

4000 |

2500 |

2500 |

|

Voltage(V) |

380 |

380 |

380 |

|

Temperature control |

PID automatic control (temperature control accuracy ± 1 ℃ ) and manual control. |

||

|

Heating mode |

Induction heating |

||

|

Working atmosphere in furnace |

Vacuum replacement Ar or N 2 protection (micro positive pressure). |

||

|

Protection mode |

Siemens PLC intelligent early warning, alarm and power supply safety protection. |

||

|

Cooling mode |

Water cooling system |

||

Heat ins

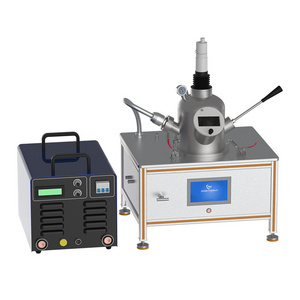

Multi angle device photos:

Main configuration:

The complete set of equipment consists of power supply (distribution cabinet, temperature control instrument, alarm system, etc.), reactive power compensation device (capacitor, transformer), furnace body (furnace shell, inductor, internal support, charging crucible, vacuum system, insulation layer, etc.), temperature measurement and control system (Japan island power FP93, infrared thermometer, etc.), vacuum system(pipeline, mechanical pump, air breaking valve, safety valve, digital display pressure sensor, vacuum meter, etc.) The temperature measurement and control system can be seamlessly connected with the upper computer through PLC to monitor, control and display the operation of the whole set of equipment in real time. Realize the sequential control and interlocking protection of power supply, furnace body, cooling water, protective gas, purification and other devices, and have the functions of early warning, alarm and so on.

More details about packaging:

Packing:

Whole machine and every parts wrapped by plastic film for dusting-proof.

Packed in export standard wooden case with pallet, conducive to forklift handling.

Shipping:

Shipping method: by sea, by air, by international express company.

Delivery time: 30-45 days after order confirm.

Forwarder: We have shipping forwarder agent for sending the goods to all over the world, can arrange shippment to destination port and to door for customer. We also accept forwarder agent of customer.