- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V or Customized is available

-

Dimension(L*W*H):

-

Depends on model

-

Weight:

-

1600 KG

-

Product Name:

-

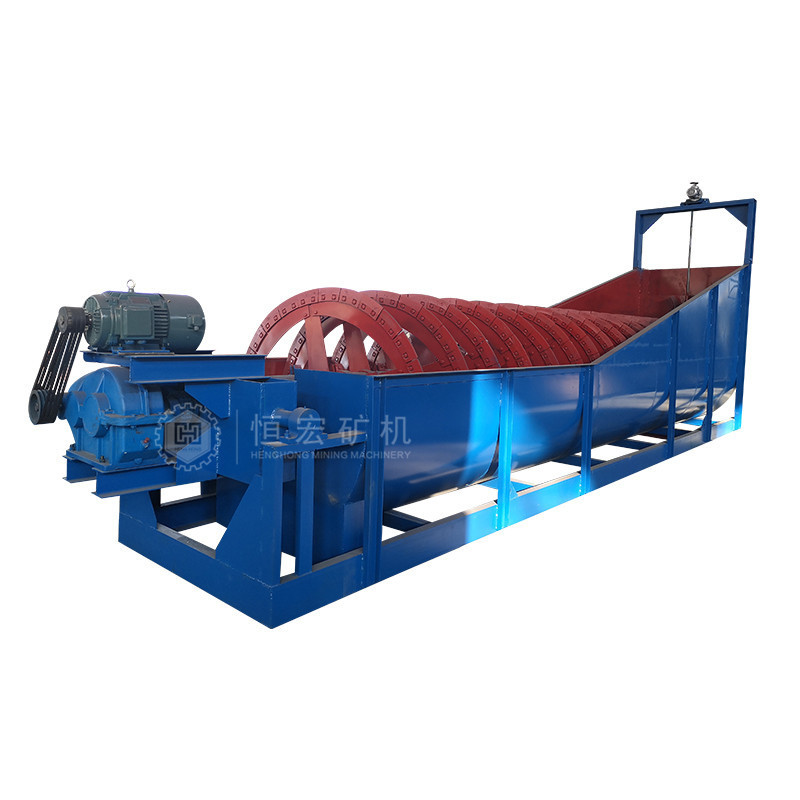

Clean Coal Washing Machine 220V/380V Spiral Classifier Price

-

Length:

-

4500mm

-

Width:

-

555mm

-

Returing quantity:

-

143~261 m3/day

-

Runing speed:

-

10.5r/min

-

Color:

-

As your request

-

Keywords:

-

Spiral Classifier,Screw Classifier,Alluvial Gold Mining Machine

-

MOQ:

-

1 Set

-

Price:

-

Negotiation

-

Advantages:

-

Professional Manufacturer,High Capacity,Easy Operation

Quick Details

-

Production Capacity:

-

90%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Henghong Sand Spiral Classifier

-

Voltage:

-

220V/380V or Customized is available

-

Dimension(L*W*H):

-

Depends on model

-

Weight:

-

1600 KG

-

Product Name:

-

Clean Coal Washing Machine 220V/380V Spiral Classifier Price

-

Length:

-

4500mm

-

Width:

-

555mm

-

Returing quantity:

-

143~261 m3/day

-

Runing speed:

-

10.5r/min

-

Color:

-

As your request

-

Keywords:

-

Spiral Classifier,Screw Classifier,Alluvial Gold Mining Machine

-

MOQ:

-

1 Set

-

Price:

-

Negotiation

-

Advantages:

-

Professional Manufacturer,High Capacity,Easy Operation

Main Features

100% Original factory sale

Strong washing ability,small power consumption

Suitable for various working environments

Use high quality iron steel materials for durable working and low maintenance rate

Simple structure, stable operation, safe and reliable

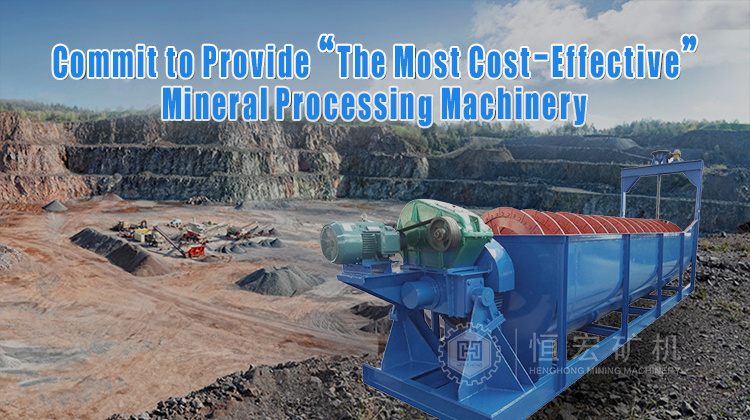

High Performance Ball Mill Classifier Sand Production Line Clean Coal Washing Machine 220V/380V Spiral Classifier Price

Jiangxi Henghong mining machinery is devoting to provide turnkey solution with worldwide clients for mineral processing plant including research, design, manufacture,installation and commissioning, personnel training, after-sale service and management of processing plant. Up to now, we have developed some major product lines: they are mining crushing machine, mining milling machine,mining classifying separator, mining flotation machine, mining magnetic separator, mining gravity separator and gold

smelting furnace.When you find us,you find one best mining machinery

manufacturer.

Spiral Classifier Introduction

Screw Type Spiral Classifier is one of beneficiation equipment, based on user requirements,It is widely

used to combine with the ball grinder in a closed circulation for ore-sand separation in the ore separation plant., classify ore sand and fine silt in the gravity separation plant, classify the granularity from the pulp in the metal ore beneficiations flow and remove the slime and water in the ore washing process.

Widely Applications

It is suitable for grading more than 200 kinds of metal ore and non-metal ore, and is used in mineral processing, water conservancy, coal, building materials and other industries.

1.Suitable for distributing ore in concentrator with ball mill in closed-circuit circulation.

2.Suitable for grading ore and fine mud in gravity concentrator.

3.Particle size classification of slurry in metal ore dressing process.

4.Desilting and dewatering operations in ore washing operations.

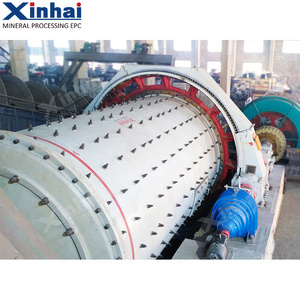

Spiral Sand Washing Machine Working Principle

1.Gearing:

The transmission of spiral is achieved by motor through V-belt.

2.Spiral: It is the main components of this machine, it formed by the main shaft, frame, spiral blades,

2.Spiral: It is the main components of this machine, it formed by the main shaft, frame, spiral blades,

lining iron frame. The frame, spiral blades, linked iron are formed to connected spiral surface, because the shaft is constantly rotating, so the role of helical face is mixing the slurry , make fine particles flow from

the overflow weir, coarse mineral particles conveyor from the screw first to discharge

port.

3.Cell:

Welded by steel plate and shaped steel, it is the body of screw classier.

4.Lifting mechanism: The movement of machine screw parts is achieved through the cycloid reducer,

4.Lifting mechanism: The movement of machine screw parts is achieved through the cycloid reducer,

gear, screw. When classifier stop working, the materials in the water chute will precipitated, in order to avoid damage by precipitation and the transmission will occurs over load when it move again, so must lift the screw spindle from water chute and make it leave the precipitation level, for this design lifting mechanism.

|

Type

|

Model

|

Spiral Speed

(r/min) |

Chute Length

(mm) |

Capacity of Returning

(t/d) |

Capacity of Overflow

(t/d) |

Drive Motor Power

(kw) |

Lifting Motor Power

(kw) |

Weight

(kg) |

|

High weir single spiral classifier

|

FLG-500

|

10.5

|

4500

|

145~260

|

32

|

1.1

|

Manual operation

|

1600

|

|

|

FLG-750

|

7.8

|

5500

|

256~654

|

65

|

3

|

|

2716

|

|

|

FLG-1000

|

6.6

|

6500

|

473~1026

|

85

|

5.5

|

|

4000

|

|

|

FLG-1200

|

6

|

6500

|

1145~1600

|

155

|

5.5

|

1.5

|

7943

|

|

|

FLG-1500

|

2.5,4.4

|

8265

|

1140~2740

|

235

|

7.5

|

2.2

|

11680

|

|

|

FLG-2000

|

3.6,5.5

|

8400

|

3890~5940

|

400

|

11/15

|

3

|

20450

|

|

|

FLG-2400

|

3.6

|

9130

|

6800

|

580

|

22

|

3

|

24194

|

|

|

FLG-3000

|

3.2

|

12500

|

11625

|

890

|

30

|

4

|

37000

|

|

High weir double spirals classifier

|

2FLG-1200

|

6

|

6500

|

2340~3200

|

310

|

5.5×2

|

1.5×2

|

15840

|

|

|

2FLG-1500

|

2.5,4.6

|

8250

|

2280~5480

|

470

|

7.5×2

|

2.2×2

|

22100

|

|

|

2FLG-2000

|

3.6,5.5

|

8400

|

7780~11880

|

800

|

15×2

|

3.0×2

|

34621

|

|

|

2FLG-2400

|

3.67

|

9130

|

13600

|

1160

|

18.5×2

|

3.0×2

|

42460

|

|

|

2FLG-3000

|

3.2

|

12500

|

23300

|

1785

|

22×2

|

4.0×2

|

73030

|

|

Submerged single

spiral classifier |

FLC-1000

|

5

|

8400

|

473~1026

|

75

|

5.5

|

Manual operation

|

5225

|

|

|

FLC-1200

|

5,6,7

|

8400

|

1150~1640

|

120

|

7.5

|

2.2

|

9583

|

|

|

FLC-1500

|

2.5,4.6

|

10500

|

1830~2740

|

185

|

7.5

|

2.2

|

14226

|

|

|

FLC-2000

|

3.6,5.5

|

12900

|

3240~5940

|

320

|

11/15

|

3

|

27753

|

|

|

FLC-2400

|

3.6

|

14130

|

6800

|

455

|

18.5

|

4

|

32467

|

|

|

FLC-3000

|

3.2

|

14300

|

11650

|

705

|

30

|

4

|

43500

|

|

Submerged double

spirals classifier |

2FLC -1200

|

6

|

8400

|

2340~3260

|

240

|

7.5×2

|

1.5×2

|

19610

|

|

|

2FLC-1500

|

2.5,4.6

|

10500

|

2280~5480

|

370

|

7.5×2

|

2.2×2

|

27450

|

|

|

2FLC-2000

|

3.6,5.5

|

12900

|

7780~11880

|

640

|

15×2

|

3.0×2

|

50000

|

|

|

2FLC-2400

|

3.6

|

14130

|

13700

|

910

|

18.5×2

|

4.0×2

|

65283

|

|

|

2FLC-3000

|

3.2

|

14300

|

23300

|

1410

|

22×2

|

4.0×2

|

84900

|

Q: 1.What is your machine used for ?

A: Spiral Classifier Machine is used for washing & classifying the materials such as Sand,Gold,Copper,Mineral etc.

Q: 2.Are you factory or trade company?

A: Yes dear,we are the Professional manufacturer from 1985.So we could give you original factory price than those trade companies.

We're also warmly welcome your Visiting our factory if you are Coming to China,Please Call at +86-18870736160

Q: 3.Can I operate it well, if I have no experience?

A: Do not worry! Our machines is designed to use easily.You are welcome to visit our company to be trained here,And we could arrange the engineer to go to your country/company to train your workers directly as your requested and the relative travel cost will be on your account.

Q: 4.Can you send me the video to show how the machine works?

A: Surely.we have made video of every machine,so if you need we can send for you to checking in clearly.

Q: 5. What should I take care when using the machine?

A: Please using the machine in regular and Keeping the machine away from thinner and other chemical liquid.

Q: 6.How about your Service ?

A: All of our machines have one year warranty and Wholelife Technology support to make sure your machine work well.

Q: 7.How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: 8.What about the payment method?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shipment.

Q:9.What's Information we need from your side ?

1).What kind of ore do you want to process ?

2).What minerals do you want to get finally?

3).What's the processing capacity per hour do you need ?

4).What's the maximum feeding size of your ore ?

5).Your stimated purchase time?

A: Spiral Classifier Machine is used for washing & classifying the materials such as Sand,Gold,Copper,Mineral etc.

Q: 2.Are you factory or trade company?

A: Yes dear,we are the Professional manufacturer from 1985.So we could give you original factory price than those trade companies.

We're also warmly welcome your Visiting our factory if you are Coming to China,Please Call at +86-18870736160

Q: 3.Can I operate it well, if I have no experience?

A: Do not worry! Our machines is designed to use easily.You are welcome to visit our company to be trained here,And we could arrange the engineer to go to your country/company to train your workers directly as your requested and the relative travel cost will be on your account.

Q: 4.Can you send me the video to show how the machine works?

A: Surely.we have made video of every machine,so if you need we can send for you to checking in clearly.

Q: 5. What should I take care when using the machine?

A: Please using the machine in regular and Keeping the machine away from thinner and other chemical liquid.

Q: 6.How about your Service ?

A: All of our machines have one year warranty and Wholelife Technology support to make sure your machine work well.

Q: 7.How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: 8.What about the payment method?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shipment.

Q:9.What's Information we need from your side ?

1).What kind of ore do you want to process ?

2).What minerals do you want to get finally?

3).What's the processing capacity per hour do you need ?

4).What's the maximum feeding size of your ore ?

5).Your stimated purchase time?

Warmly Welcome to Sending Inquiry,We will give 100% positive responses.

Hot Searches