- Product Details

- {{item.text}}

Quick Details

-

Range of Spindle Speed(r.p.m):

-

65 - 4660 r.p.m

-

Place of Origin:

-

China

-

Brand Name:

-

INTEGRITY

-

Model Number:

-

X6328B

-

Table Travel (mm):

-

1120*260

-

Year:

-

New

-

Weight (KG):

-

1350

-

CNC or Not:

-

Normal

-

Table size (mm):

-

1120*260

-

Application:

-

Metal processing

-

Power(W):

-

2.2 KW

Quick Details

-

Table Travel (X) (mm):

-

600 mm

-

Table Travel (Y) (mm):

-

270 mm

-

Table Travel (Z) (mm):

-

300 mm

-

Range of Spindle Speed(r.p.m):

-

65 - 4660 r.p.m

-

Place of Origin:

-

China

-

Brand Name:

-

INTEGRITY

-

Model Number:

-

X6328B

-

Table Travel (mm):

-

1120*260

-

Year:

-

New

-

Weight (KG):

-

1350

-

CNC or Not:

-

Normal

-

Table size (mm):

-

1120*260

-

Application:

-

Metal processing

-

Power(W):

-

2.2 KW

PRODUCT DESCRIPTION

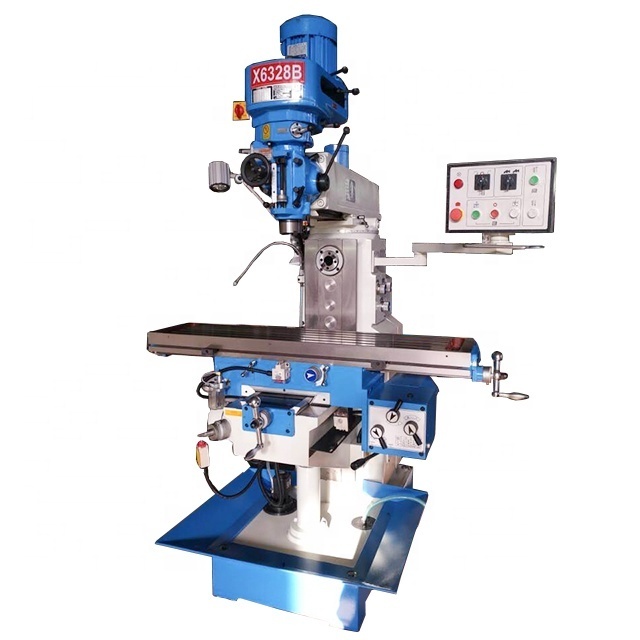

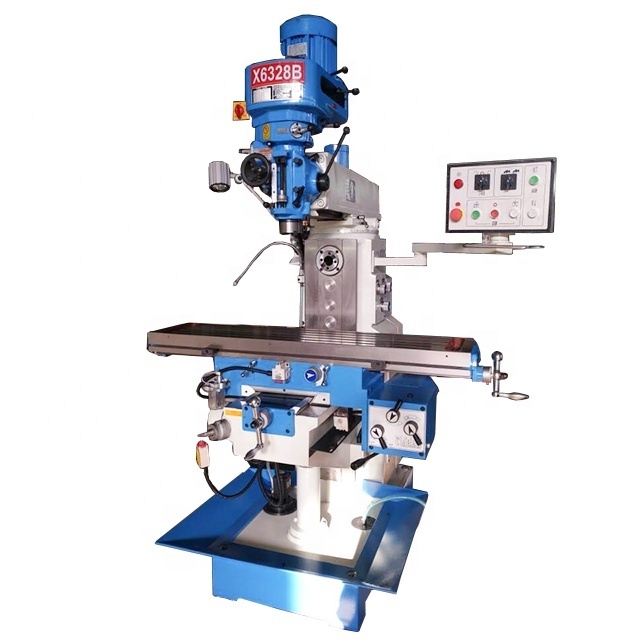

Universal Radial Milling Machine X6328B table 10"X44"

|

unit

|

X6328B

|

|

TABLE :

|

|

|

|

Table size

|

|

mm

|

1270x280

|

|

T slot

|

no

|

|

3

|

T Size ( Width )

|

|

mm

|

14

|

|

T Centre distance

|

mm

|

|

63

|

Max. load of Table

|

|

kg

|

230

|

|

machining range :

|

|

|

|

X table Longitudinal travel(manual/auto)

|

|

mm

|

750

|

|

Y table Cross travel (manual/auto)

|

mm

|

|

300

|

Z table Vertical travel(manual/auto)

|

|

mm

|

400

|

|

MAIN SPINDLE :

|

|

|

|

Spindle taper

|

|

|

ISO40

|

|

Spindle speed /step -- Vertical

|

rpm

|

|

65-4660

|

--Horizontal

|

|

rpm

|

38-1310/12steps

|

|

Max.drilling dia.

|

mm

|

|

30

|

Max.end milling width

|

|

mm

|

100

|

|

Max. vertical milling Dia.

|

mm

|

|

25

|

Max.tapping dia.

|

|

mm

|

M16

|

|

quill travel

|

mm

|

|

127

|

swivel angle of headstock

|

|

degree

|

±45º

|

|

vertical spindle axis to column surface

|

mm

|

|

200-760

|

vertical spindle nose to table surface

|

|

mm

|

100-500

|

|

horizontal spindle axis to table surface

|

mm

|

|

0-350

|

horizontal spindle axis to arm bottom

|

|

mm

|

175

|

|

arm travel

|

mm

|

|

500

|

FEEDS :-

|

RECOMMENDED PRODUCT

COUPONS

Q1:How long guarantee period you offer?/ how is warranty?

A1:12 month guarantee after machine on board.

Q2: What services are available during the guarantee period?

A2: Free replacing parts available in the warranty period.cost-value replacing parts available beyond thewarranty period.Quick action and reply for the technical questions at any time.

Q3: Can you provide training for operation CNC machines?

A3: Yes, free training in our factory or engineer overseas service available as customerrequirements(relative cost born by customer.

Q4: Can you provide customized machine or Special purpose machine?

A4: Yes, we provide different kinds processing solutions for customers, in order to meet differentrequirements.

Q5: Can we visit your factory before order?

A5: Sure, we warmly welcome you to visit our factory at any time. The more you know us, the more youtrust us! So you can rest assured on our quality products and our best services.

Q6: Where is your factory located?

A6:Our factory is located in Kunming city, Yunnan province, in the southwest of China.

Hot Searches