- Product Details

- {{item.text}}

Quick Details

-

Production Speed(Cycles/min):

-

30times/minute

-

Air Pressure(MPa):

-

0.6 MPa

-

Sheet Thickness(mm):

-

0.15 - 0.7 mm

-

Heating Power (kW):

-

7 kW

-

Air Comsumption(L/min):

-

0.3 L/min

-

Water Comsumption(L/min):

-

0.1 L/min

-

Place of Origin:

-

SHANGHAI

-

Brand Name:

-

SY

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3500*1000*1800mm

-

Weight (T):

-

2.4 T

-

Power(KW):

-

11.5

-

Max.Formed Area:

-

60-290mm

-

Stroke Range:

-

60-300mm

-

Mold cooling:

-

60L/H tap water/recycle water

Quick Details

-

Max.Forming Height(mm):

-

47 mm

-

Forming Width (mm):

-

290 mm

-

Forming Length (mm):

-

470 mm

-

Production Speed(Cycles/min):

-

30times/minute

-

Air Pressure(MPa):

-

0.6 MPa

-

Sheet Thickness(mm):

-

0.15 - 0.7 mm

-

Heating Power (kW):

-

7 kW

-

Air Comsumption(L/min):

-

0.3 L/min

-

Water Comsumption(L/min):

-

0.1 L/min

-

Place of Origin:

-

SHANGHAI

-

Brand Name:

-

SY

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3500*1000*1800mm

-

Weight (T):

-

2.4 T

-

Power(KW):

-

11.5

-

Max.Formed Area:

-

60-290mm

-

Stroke Range:

-

60-300mm

-

Mold cooling:

-

60L/H tap water/recycle water

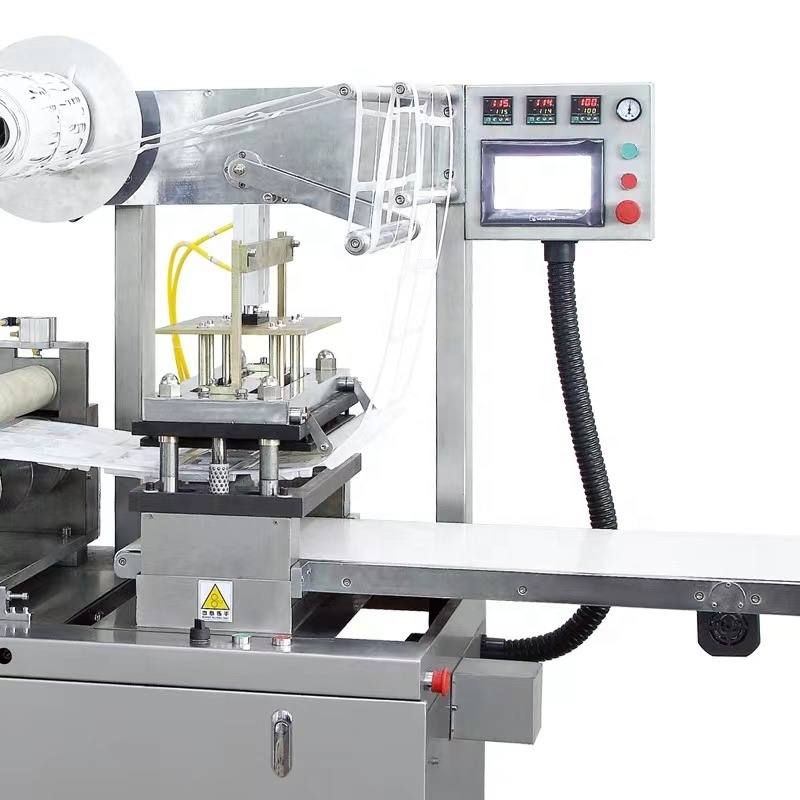

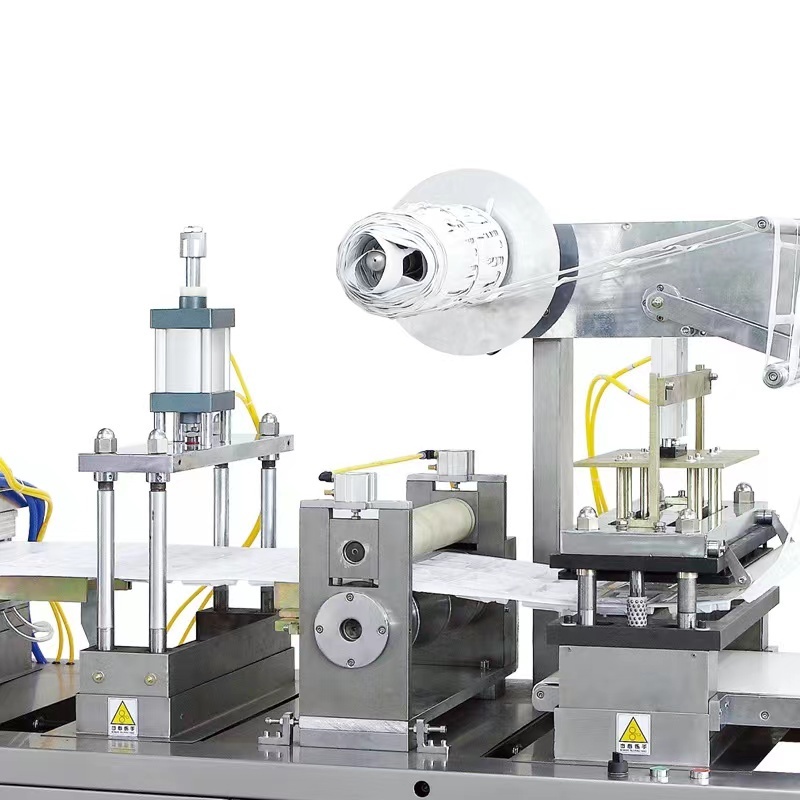

Product description SY-500C series automatic blow molding, blister cup lid forming machine is developed by our scientific research personnel according to the actual packaging market demand. Absorbing the advantages of aluminum-plastic blister packaging machine and blister molding machine, it is a new product developed according to the requirements of pharmaceutical "GMP" and food "QS" standards. , punching, punching, automatic process operation, advanced technology, safe and easy operation, avoid labor consumption caused by manual punching in the past and pollution caused by contact with employees at work, and ensure the quality requirements in the production process. The equipment adopts plate heating production, which consumes less power, has a small footprint and is economical and practical. It is widely used in the production of food, medicine, hardware and other industries.

Performance characteristics:

1. The mechanical transmission adopts a reducer to connect with the main shaft, and the main shaft is on the same axis line (reduce transmission error)

2. The pneumatic system adopts photoelectric control and programmable through PLC, so that each mechanism can run accurately and make the packaging products in multiple stations, The stability of

desynchronization is guaranteed in long-distance operation.

3. The host adopts frequency conversion speed regulation, the stroke can be adjusted arbitrarily, the replacement of the mold is easy, and the servo motor is traction and runs reliably.

4. Positive pressure forming (blow forming). Applied to PVC, PET, PS Medical trays, beverage cup lids, food packaging

boxes and other plastic products are well received by users at home and abroad.

|

Punch speed

|

15-32 punch/min

|

|

Max.Forming size

|

60-290mm

|

|

Max.Forming depth

|

52mm

|

|

Max.Material width

|

420mm

|

|

Stroke Range

|

60-300mm

|

|

Compressed air

|

0.6-0.8Mpa

|

|

Mold cooling

|

60L/H tap water/recycle water

|

|

Total power

|

11.5Kw

|

|

Main motor power

|

2.2Kw

|

|

Material thickness

|

0.15-0.7mm

|

|

Overall dimension

|

2900*1000*1800MM

|

|

Packing Size

|

3500*1000*1800mm

|

|

Weight

|

2400KG

|

Hot Searches