1.

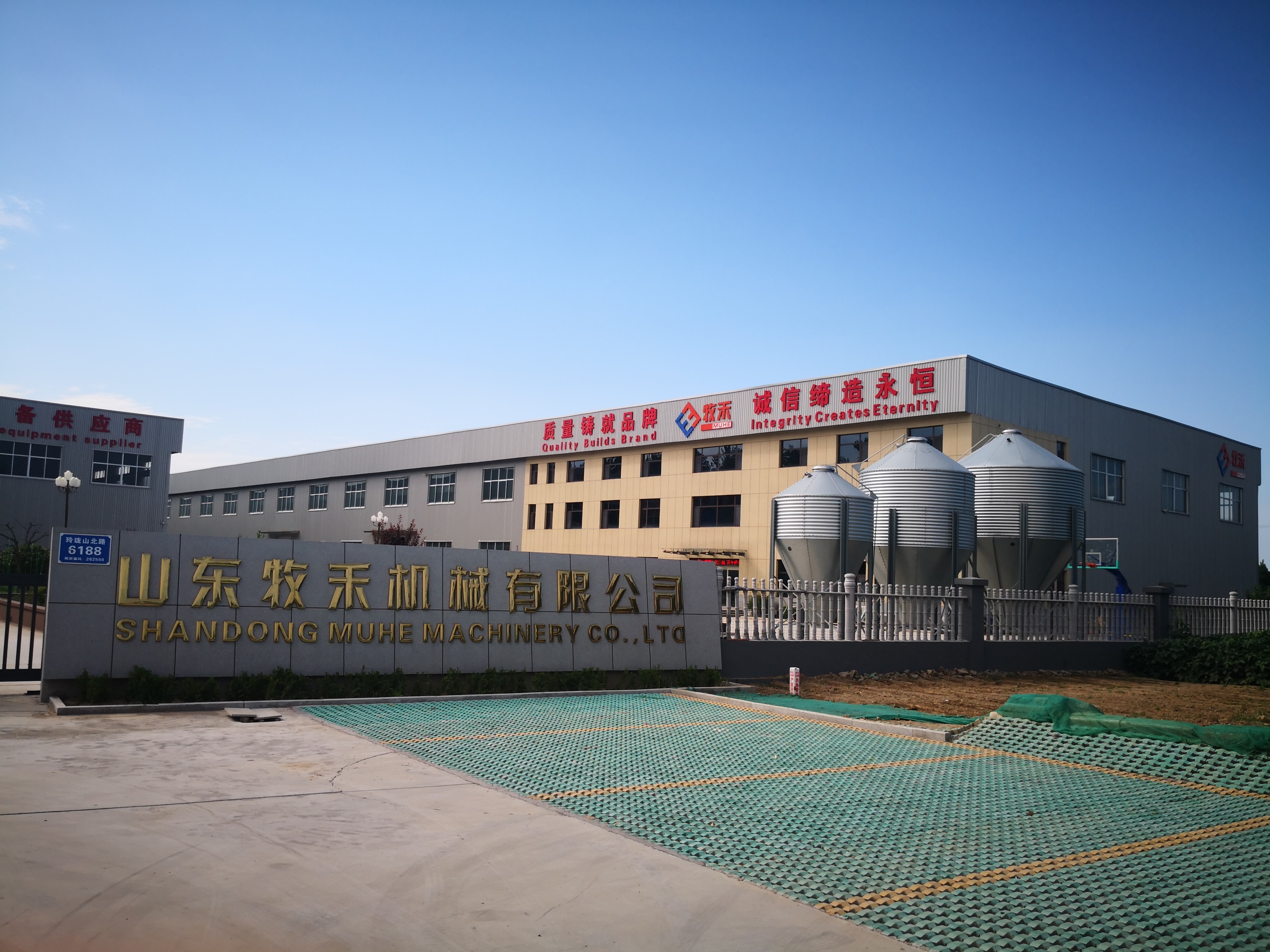

Totally New Machine;

2.

Sufficient Production Capacity;

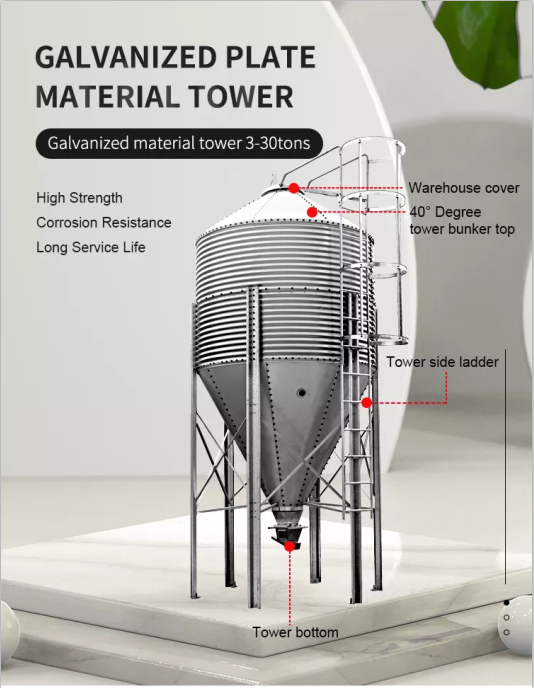

3. Produce Different Size Silo to Meet

Customers' Need;