- Product Details

- {{item.text}}

Quick Details

-

Product Type:

-

Aluminium die casting service

-

Product material:

-

aluminium, zinc, etc.

-

Product application:

-

Home appliances, auto parts, communication equipment, etc.

-

Mould Material:

-

Mould steel P20, 718, 718h, 718hh, 2738, 2344, 2316, S136, NAK80

-

Mould Structure:

-

Die casting mould

-

Certification:

-

ISO9001:2015

-

OEM/ODM:

-

Acceptable

-

Mould life:

-

80000-100000 shots

Quick Details

-

Place of Origin:

-

Guangdong, China, Guangdong,China

-

Brand Name:

-

LvDa, RD MOULD

-

Model Number:

-

LD-MJ-029

-

Product Type:

-

Aluminium die casting service

-

Product material:

-

aluminium, zinc, etc.

-

Product application:

-

Home appliances, auto parts, communication equipment, etc.

-

Mould Material:

-

Mould steel P20, 718, 718h, 718hh, 2738, 2344, 2316, S136, NAK80

-

Mould Structure:

-

Die casting mould

-

Certification:

-

ISO9001:2015

-

OEM/ODM:

-

Acceptable

-

Mould life:

-

80000-100000 shots

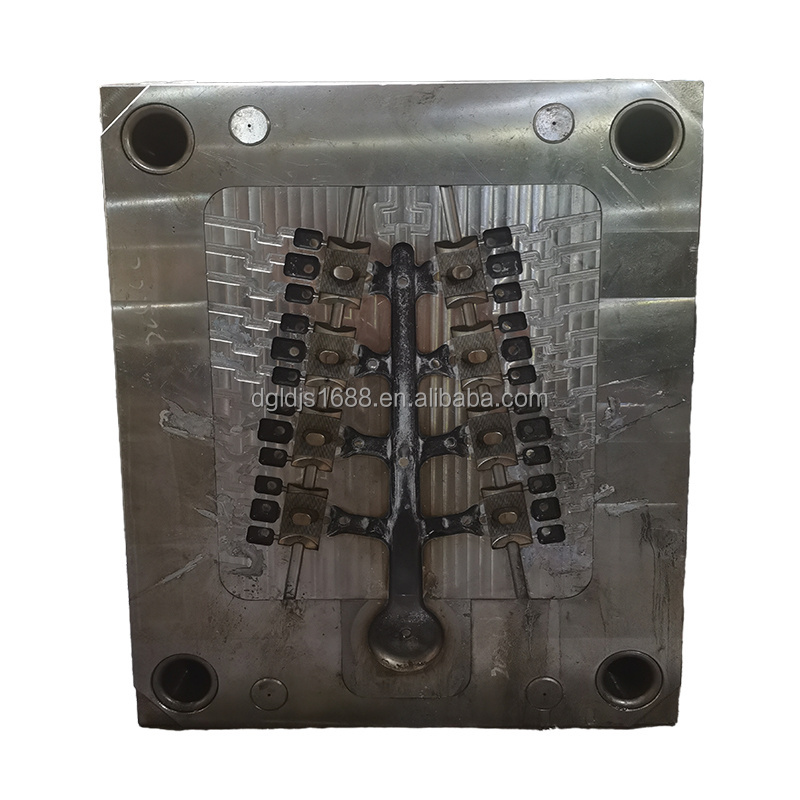

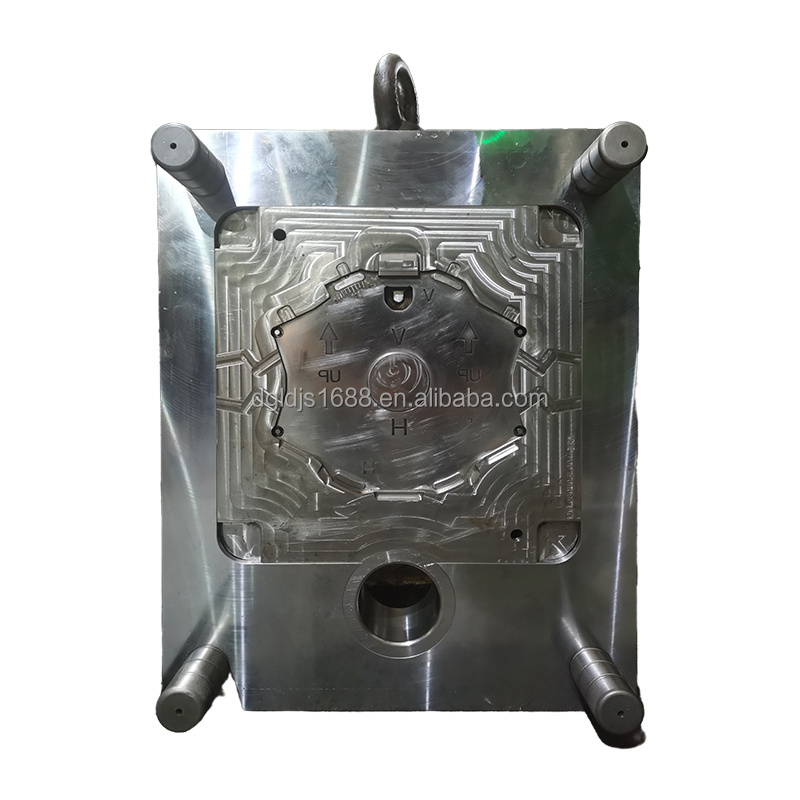

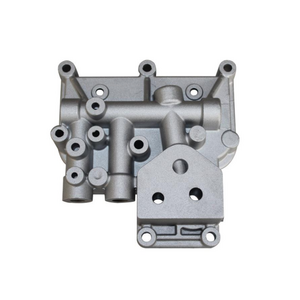

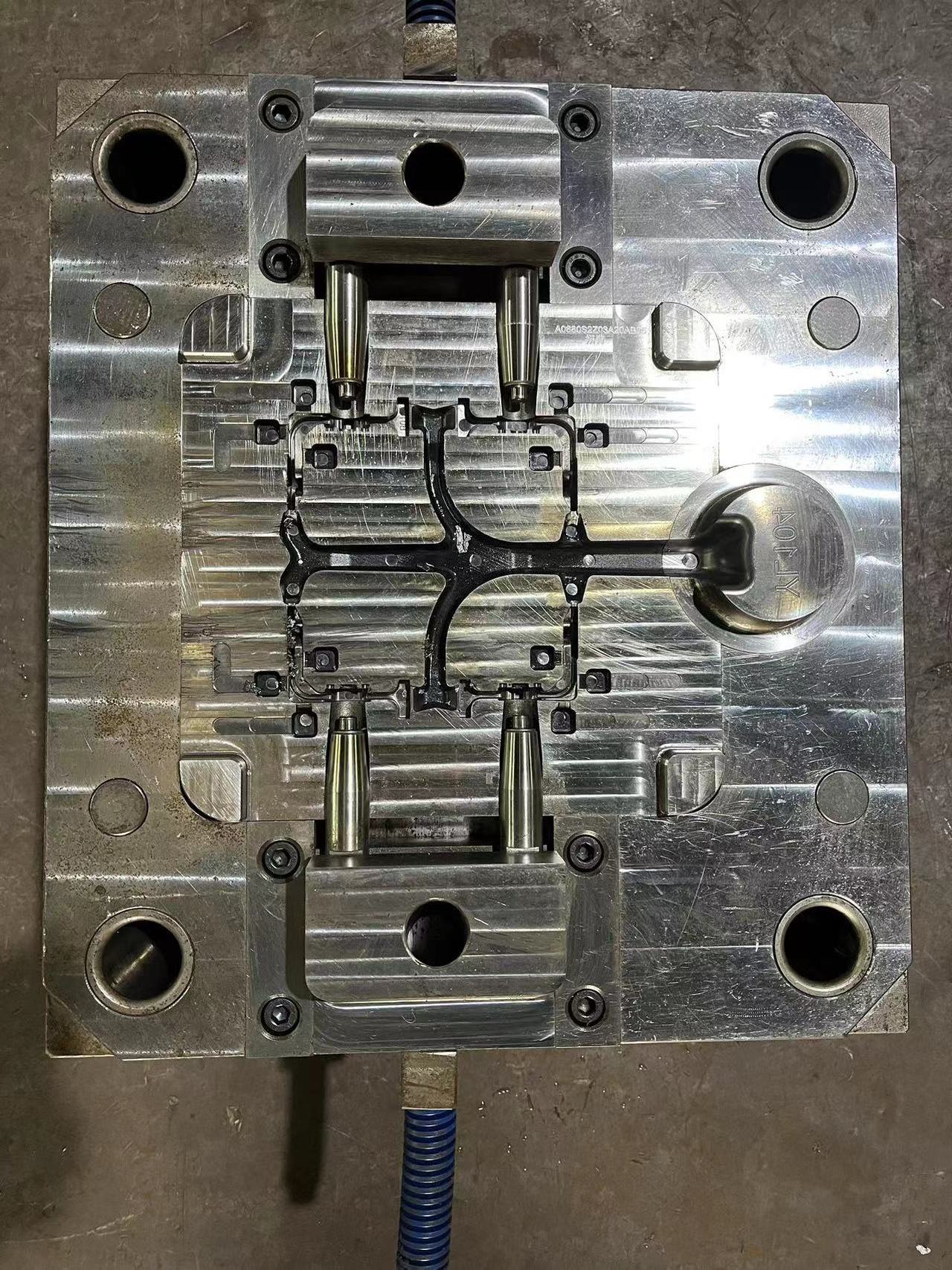

Product Image

Product Information

|

Product type

|

Aluminum / zinc alloy die casting mold

|

|

|

|

|||

|

Mould Structure

|

Die casting mould

|

|

|

|

|||

|

Mould material

|

Mould steel P20, 718, 718h, 718hh, 2738, 2344, 2316, S136, NAK80

|

|

|

|

|||

|

Mould base

|

LKM,HASCO,JLS ,DEM etc.

|

|

|

|

|||

|

Mould life

|

80000-100000 shots

|

|

|

|

|||

|

Cavity

|

Single & Multi- cavity

|

|

|

|

|||

|

Process

|

Machining, casting, die casting, punching/stamping, extrusion, welding, laser cutting

|

|

|

|

|||

|

Certification

|

ISO9001:2015

|

|

|

|

|||

|

Design software

|

UG, Pro/E, CAM, Solidworks, Auto CAD

|

|

|

|

|||

|

EM/ODM

|

Acceptable

|

|

|

|

|||

|

Product material

|

Aluminium (6061, 7075, A380 etc), zinc, etc.

|

|

|

|

|||

|

Product sizes

|

Custom size and thickness according to customer's requirement

|

|

|

|

|||

|

Product colors

|

According to the customer's requests

|

|

|

|

|||

|

Product Surface finish

|

polished (high polish, mirror polish), smooth, blasting, vibrating, anodizing (standard o hard anodizing), painting,

powder coating, blackening, etc.

|

|

|

|

|||

|

Product Performance

|

scracth resistant, flame resistant, UV resistant,chemical resistant, heat treatment to different hardness/strength,

rust-resistant, high precision,etc. |

|

|

|

|||

|

Application of the product

|

Aluminium die casting parts making,used for household commodities, electronics, car parts OME & Performance, motorcycles,bikes,machinery parts, hospital, cosmetics, Military and Aerospace etc.

|

|

|

|

|||

|

Custom service

|

Customized color/size/different product material maching/Logo/pattern/external packing

|

|

|

|

|||

|

Payment terms

|

50% deposit,50% balance before delivery

|

|

|

|

|||

|

Delivery

|

shipping by air/by sea/railway transportation/land transportation

|

|

|

|

|||

|

Business Fields

|

Project Development (ODM&OEM project) for Industrial Design, ME and Hardware Design, Tooling process and Mass production.Metal machining part manufacturing

|

|

|

|

|||

Recommend Products

Our Services On-demand

Production Process

Widely Applications

Die-casting Parts

About Us

■

Q1: How can I get sample?

■

A1:

Sample fee will be free if we have in stock, you just need to pay the shipping cost is OK. Sample of your own design need to pay for the mould set up charge. Samples production takes 5-7 working days after set up charge received & size drawing approval.

■

Q2:What about delivery time?

■

A2:

Stock samples take 1-2 days and custom samples take 5-7 days. The mass production time needs to be 35-60 days after receiving the deposit.

■

Q3: How to pay for the order?

■

A3:

There are 5 options to pay the order: Bank Transfer;Western Union; Paypal ; Payoneer, Alibaba Trade Assurance. Kindly choose the most suitable way for you to arrange it.

■

Q4: What is the shipping method?

■

A4:

Most of goods were sent out by international airway express company like DHL,UPS,FedEx,TNT. Usually takes around 3-4 working days (door to door service). We also can arrange shipment via sea way.

■

Q5: Are your samples free of charge?

■

A5: Yes, Free Samples will be provided within 1 week upon the mold completed

■

Q6: What parameters should we offer us for proper quotation?

■

A6: 3D & 2D drawings, request for material and surface treatment

Hot Searches