- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

55 KG

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

220V/380V/415/110V

-

Power (kW):

-

0.75 kW

-

Product name:

-

mixer tank

-

Usage:

-

Chemical Industry

Quick Details

-

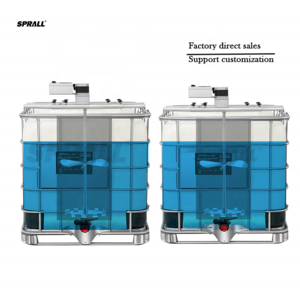

Barrel Volume (L):

-

300

-

Max. Loading Volume (L):

-

300 L

-

Range of Spindle Speed(r.p.m):

-

1 - 1400 r.p.m

-

Weight (KG):

-

55 KG

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

220V/380V/415/110V

-

Power (kW):

-

0.75 kW

-

Product name:

-

mixer tank

-

Usage:

-

Chemical Industry

Product Details

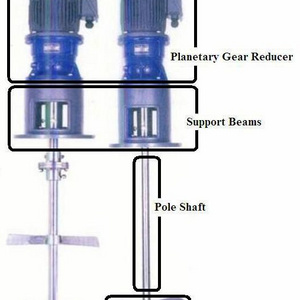

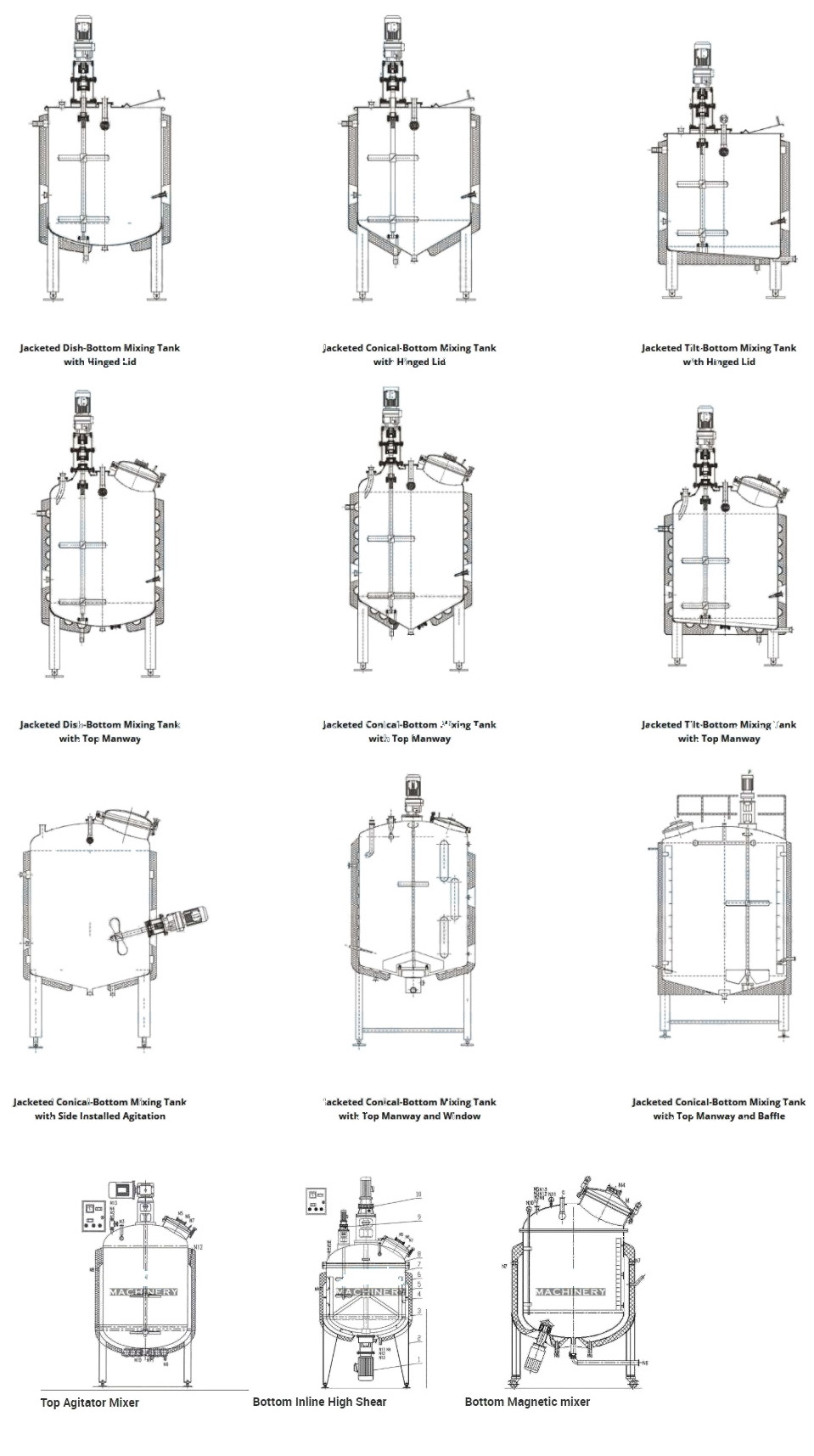

PERFORMANCE PARAMETER

Liquid mixer is mainly used for mixing raw materials. The inner lining of the pan is made of polypropylene plate or stainless steel, so it is not easy to stick to the material. Wear-resistant, the use of cycloidal pinwheel reducer/gear reducer has the characteristics of compact structure, convenient operation, uniform stirring, convenient discharging and conveying, etc.

It is suitable for use in organic fertilizer equipment, chemical equipment, industrial equipment, sewage mixing equipment production line, etc.

We have a variety of liquid mixers, some of the parameters can be customized. If you need to choose the type or are interested in this product, please send us an inquiry, there will be professional technicians to provide services for you.

|

Material

|

Stainless steel 304 ,SS316/316L,PE

|

|

PE tank

|

200L

|

|

Working Capacity

|

50-40000L,customize

|

|

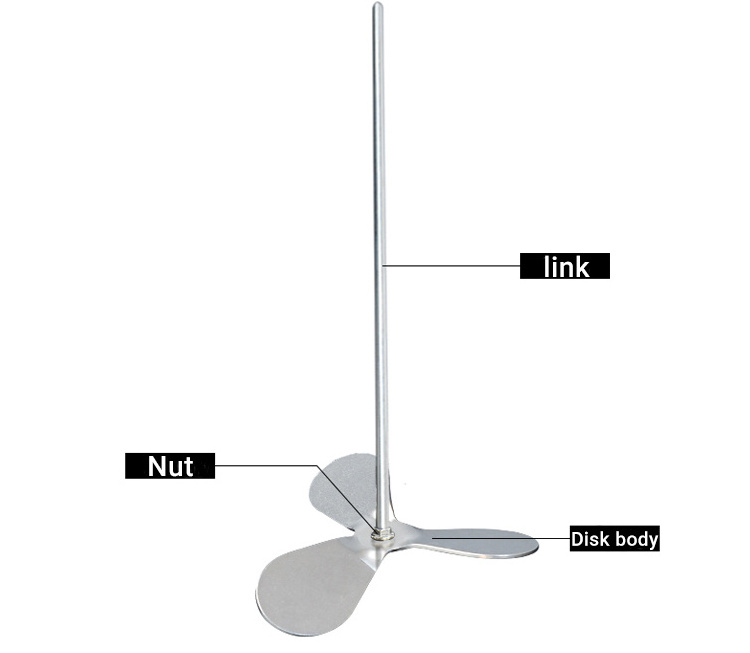

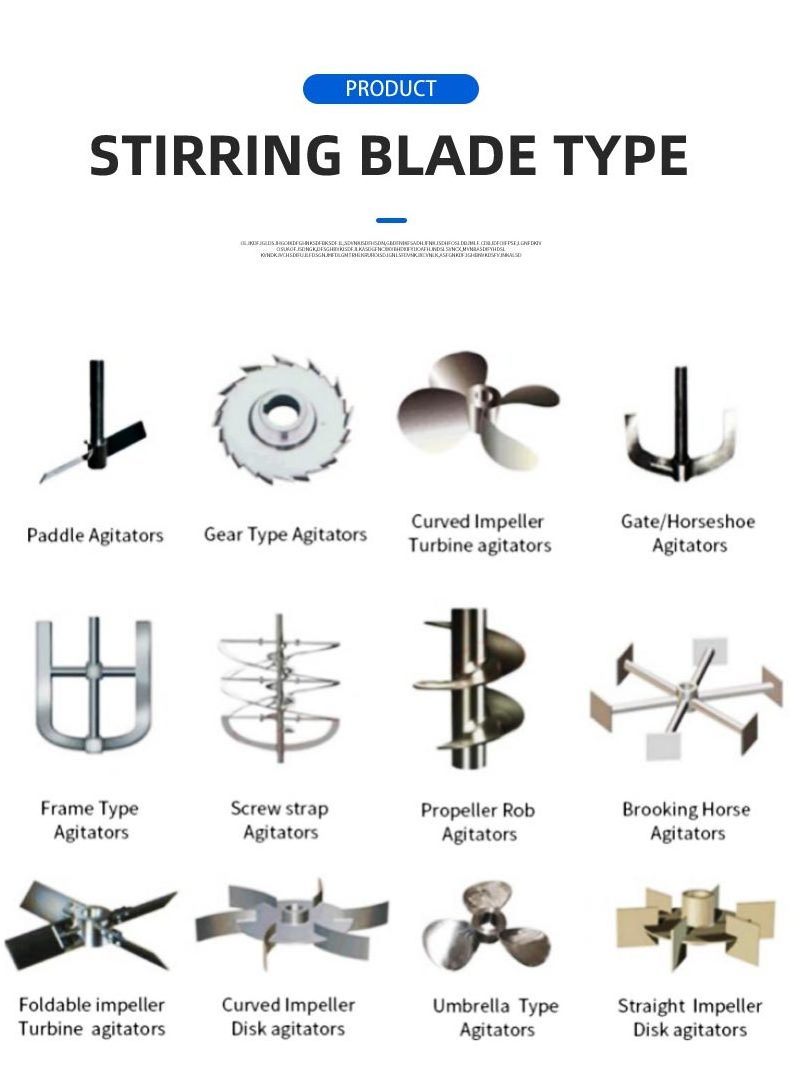

Agitator type

|

Mixer, emulsifier, disperser, etc.

|

|

Layer

|

1. Single layer type2. Double layer type: (1) dimple jacket

(2) U type jacket (3) Coil jacket 3. There layer type: add the insulation layer |

Characteristic:

a) Mixing ability:100-5000L,motor power0.37~5KW.

b) Working condition: barometric pressure,70℃.

c) Structural material:carbon steel,SS304,SS316L,lined with epoxy resin,spray PTFE.

d) Selection function:special motor,lined with epoxy resin,spray PTFE, paddle vane.

e) Working restriction:Do not start up during the emptying process and shear sensitive material.

Specification

Heating mixing tank

The electric heating stirring tank is an open-top structure, which has the functions of heating, automatic temperature control, heat preservation, and stirring; it has the advantages of fast heat transfer, large temperature differences, and convenient cleaning. It is widely used in food (dairy) products, daily chemical, beverage, oil, chemical, paint and other industries for heating, mixing or sterilization. It is especially suitable for small and pilot test use in units and scientific research institutions without steam heat source. It can also adopt a fully enclosed structure as required by the process.

high-shear emulsifier

The high-shear emulsifier uses a high-speed rotating shear- ina wheel and a stationary shearing wheel to fully and rap- idly emulsify, homogenize and disperse the mixed liquid and mixture in the tank. lt is widely used in food, beverage, biopharmaceutical, fine chemical, pigment and other in- dustries to mix and emulsify materials to improve produc tion efficiency and material quality, especially for cMc, glues, oowders and other additives that are difficult to melt. Better use

Scope of application

Hot Searches