- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

KSGER

-

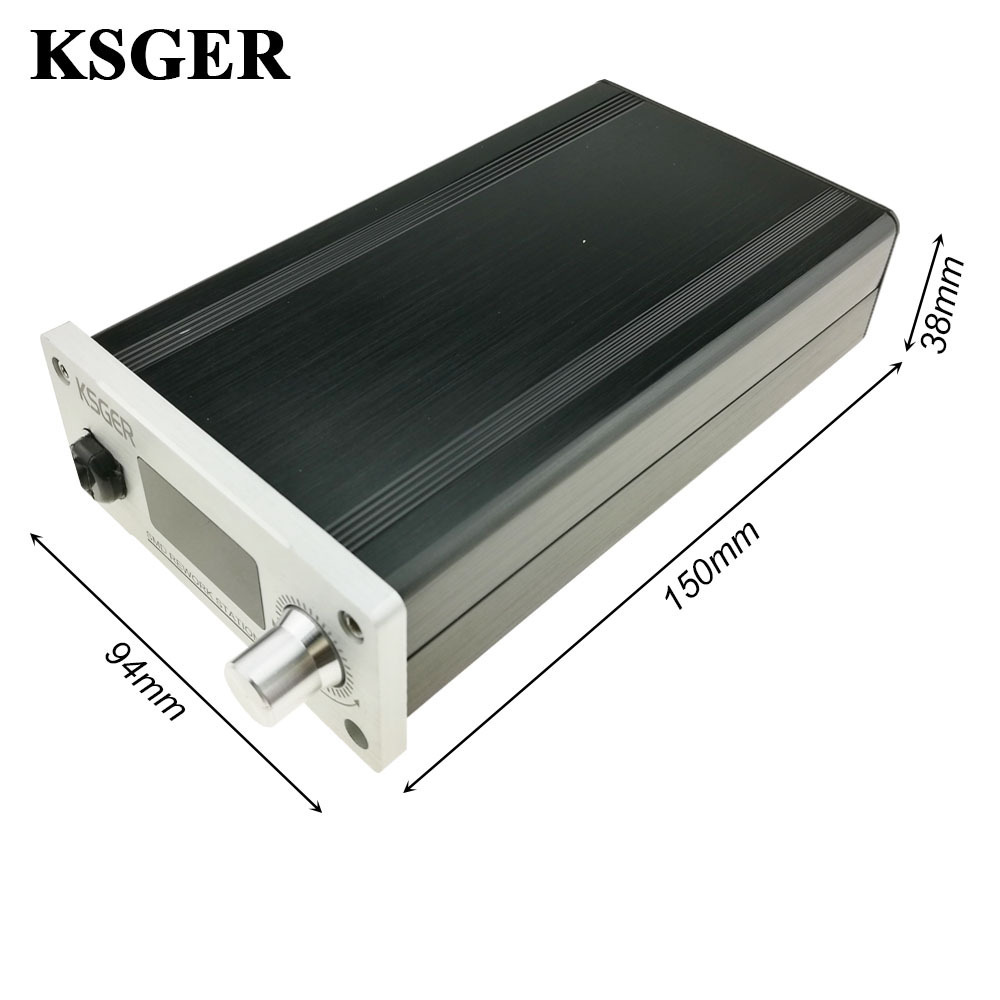

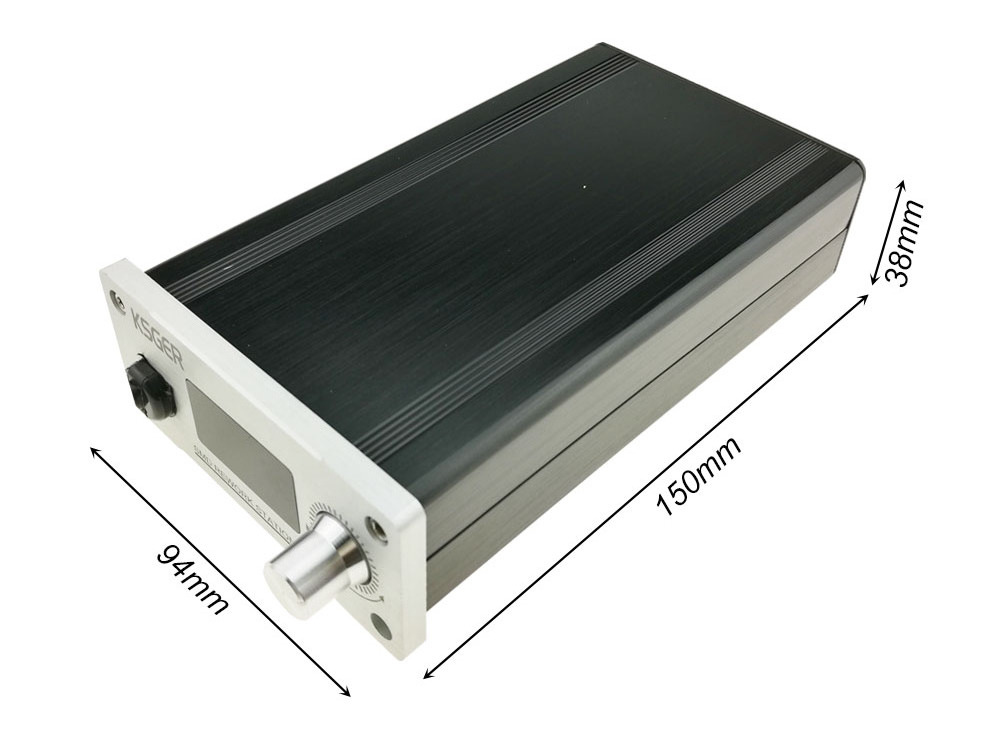

Dimensions:

-

137*88*38mm

-

Usage:

-

Repair Tools

-

Weight (KG):

-

1.5 KG

-

Output Temperature:

-

100-550C

-

Input Voltagle:

-

200-260V

-

Display:

-

1.3 inch

-

Current of Air gun fan:

-

0.3A

-

Fan Speed:

-

20%-100%

-

Case material:

-

Aluminum alloy

-

Output Power:

-

700W

-

Air gun flow:

-

120 L/min

-

Plug:

-

EU plug

-

Battery:

-

3V (CR2032)

Quick Details

-

Applicable Industries:

-

Repair Tools

-

Core Components:

-

STM32 chip

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KSGER

-

Dimensions:

-

137*88*38mm

-

Usage:

-

Repair Tools

-

Weight (KG):

-

1.5 KG

-

Output Temperature:

-

100-550C

-

Input Voltagle:

-

200-260V

-

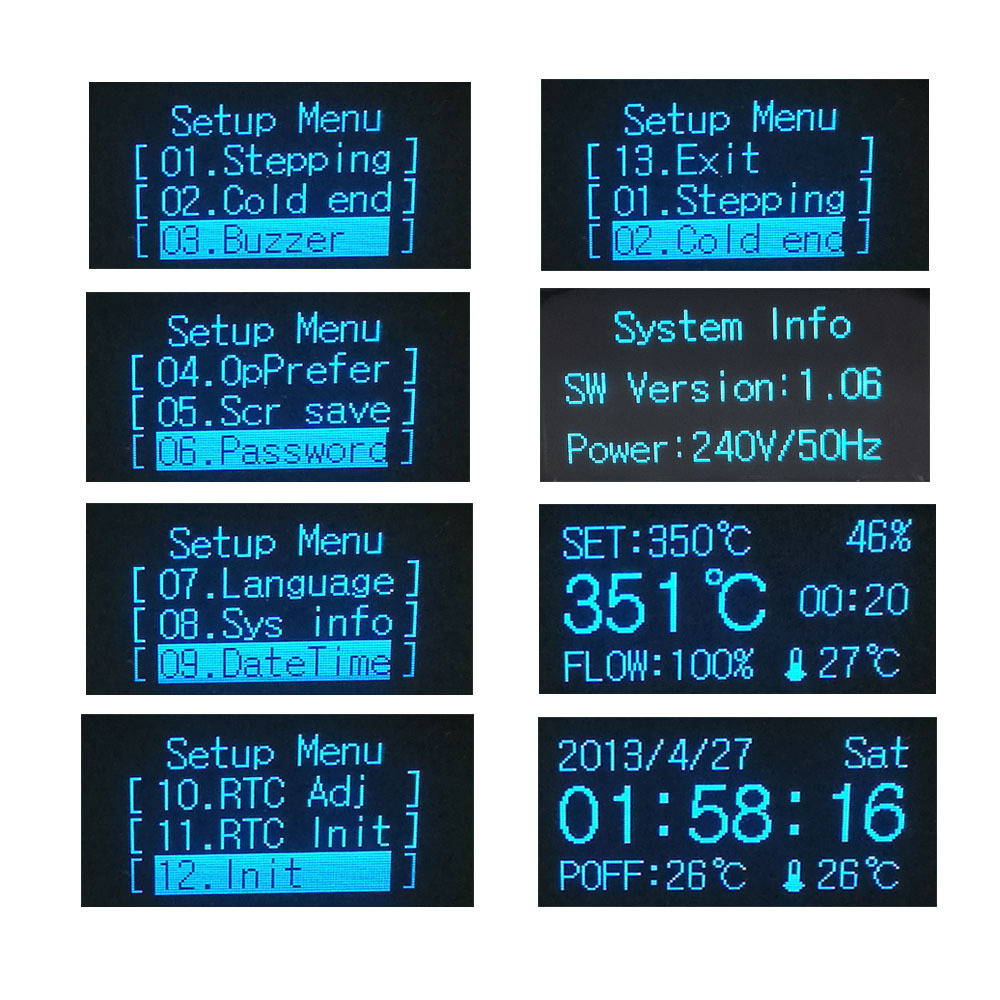

Display:

-

1.3 inch

-

Current of Air gun fan:

-

0.3A

-

Fan Speed:

-

20%-100%

-

Case material:

-

Aluminum alloy

-

Output Power:

-

700W

-

Air gun flow:

-

120 L/min

-

Plug:

-

EU plug

-

Battery:

-

3V (CR2032)

KSGER Hot Air Gun SMD Rework Station Solder Handle Hot Air Fun Electronic OLED T12 Nozzle Stand DIY Welding Tool Heating Element

Regarding the problem that the temperature displayed on the soldering station is not accurate with the actual temperature:

Please use the soldering iron tip temperature tester (please do not use a multimeter) to test the temperature. When the soldering station is working at low temperature (less than 280 degrees), the temperature displayed on the soldering station and the actual temperature of the soldering iron tip are only for reference , which is not accurate because They are affected by the surrounding environment. The surrounding environment will carry away heat, causing the soldering iron tip to lose some heat. If using a HB tip thermometer, pls make sure the soldering iron tip is suspended at the center of the temperature sensing line. If you are very strict with temperature, please do not buy this soldering station.

The problem that tin wire cannot be melted at 227 degrees.

The melting point is the melting point of the substance itself. When the temperature of the substance reaches the melting point of the substance, it is possible that the substance cannot be melted. For example, the melting point and freezing point of ice are both 0 degrees Celsius, and water does not necessarily freeze at 0 degrees Celsius. Since the temperature of the substance is affected by the surrounding environment, the actual melting point of the tin wire is higher than the melting point indicated by the tin wire. If the wire is placed in a thermostat tin furnace at 226 degrees Celsius, it is possible to melt in a sealed tin furnace. If it is wrapped around the soldering iron tip, it is impossible to melt. Because there is a gap between the tin wires, and the soldering station has a temperature difference, the soldering iron will lose some heat when it heats up, and the surrounding air will also absorb heat. The melting point of lead-free wire is 227 degrees Celsius, and the room temperature is low in winter. Under the premise of calibrating the temperature of the soldering station, at least 50 degrees Celsius should be increased to offset the heat absorbed by the air, so that the heat of the wire itself can be increased to 228 degrees Celsius.

About the wake of the handle

Please carefully understand the working principle of the vibration switch in the handle. The ball trigger switch built in the handle, the mounting direction of the ball switch and the rolling direction of the ball inside the ball switch need to vibrate the handle when the direction of the handle is consistent. For example, when the handle is vertical Please move the handle up and down. When swinging the handle up and down, please make sure that the ball inside the handle can trigger the SW wake-up mode, and the force needs to be slightly larger. When the handle is placed horizontally, please swing the handle left and right. Please swing the handle to an angle greater than 30 degrees, so that the ball inside the handle can trigger the SW wake-up mode.

About the soldering station showing of ERROR

If the ERROR is displayed, the handle or the tip is not installed properly. Please use a pair of pliers to push the tip into the innermost part of the handle. Then try rotating the tip to ensure that the tab of the tip is in good connect with the inner tab of the handle. If ERROR is still displayed and the light is always on when the tip or handle is installed, please contact us to get a solution. We encourage buyers to communicate with us to solve any problems. We will do our best for each buyer.

Hot Searches