- Product Details

- {{item.text}}

Quick Details

-

Material:

-

A356-T6

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Product name:

-

Custom Casting Parts

-

Service:

-

OEM\ODM

-

Standard:

-

GB ASTM AISI DIN BS

-

Certification:

-

IATF16949

-

Dimensions:

-

Customized Sizes

-

Quality Control:

-

100% Inspection

-

Packing:

-

Carton+Pallet

-

Application:

-

Industry

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JS

-

Model Number:

-

JS-ME68

-

Material:

-

A356-T6

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Product name:

-

Custom Casting Parts

-

Service:

-

OEM\ODM

-

Standard:

-

GB ASTM AISI DIN BS

-

Certification:

-

IATF16949

-

Dimensions:

-

Customized Sizes

-

Quality Control:

-

100% Inspection

-

Packing:

-

Carton+Pallet

-

Application:

-

Industry

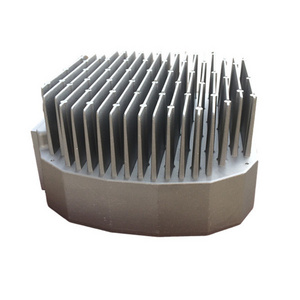

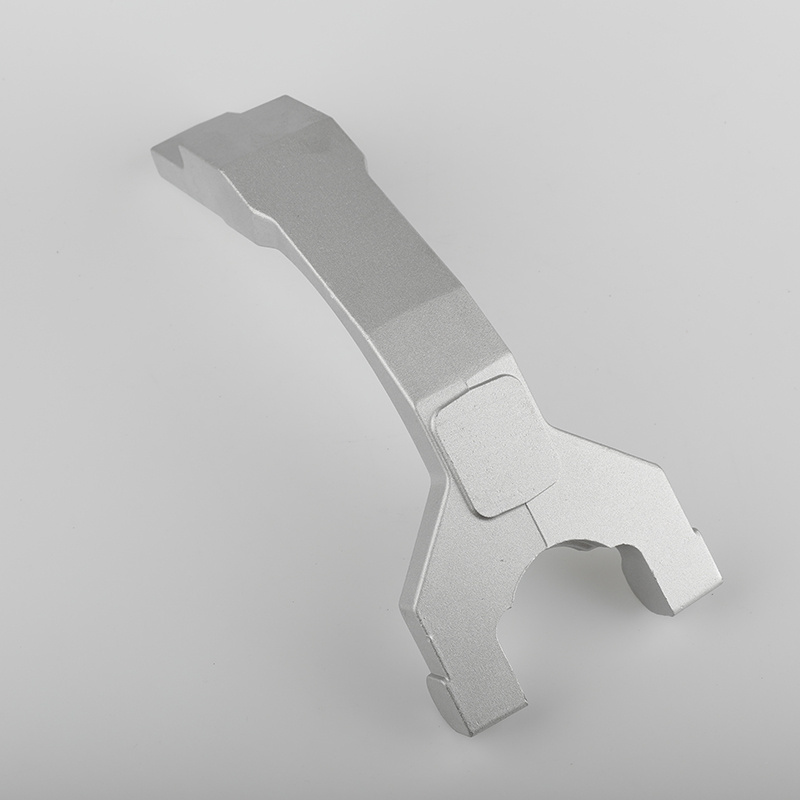

| Product Name | mechanical equipment CNC machining center machine die casting tool accessories |

| Material | aluminium alloy |

| Payment Term | T/T 30% as deposit, the balance before shipping |

| Production Artwork | Die Cast-Finishing Machining---------Final Inspection-Packing-Shipping |

| OEM | Yes,support |

| Packing&Shipping | export standand carton |

| Product Feature |

direct replacement and easy to install, perfect match, no need to cut and no more modification required. |

We have Sales Department,Financial Department, Design Department,Human Resource Department,Production Department etc.

For different customers have different products,as a manufacture,we have more than thousands of models of aluminium parts products. Our advantage that has 28 years history in this business field.

Our main products include food mechnical,aviation mechnical accessories, b ridge spot light , military project , aluminum zinc die casting parts,auto parts, mechanical equipment parts, food machinery parts, building hardware parts, ship hardware parts, kitchen supplies, medical equipment, sports equipment parts,steel mould,stainless steel products , traffic spare part, display frame, cable car fittings, electricity facilities,s e wing machine accessories, hardware parts, plastic products,copper processing, ashtry alloy, bakeware hardware, radiator, aluminium alloy joint, b ullet train dashboard , engineering machinery, new energy accessories,mechanical accessories ,bracket assembly, LED lampholder,speaker accessories, power clip tool mech a nical,PE equipment accessories,motor tube,air duster gun metal part, pump part, aluminium boat yacht accessories,industrial mechanical accessories, etc. In a word, we can make all mechanical accessories in this business field.So need to do better service.

Q1. Are you a factory or trade company?

A: We are a factory with over 28 years of gravity casting,high pressure die casting,low-pressure casting,Cold Extrusion (Aluminum&Copper),Stainless Steel (Precision Casting)and Silica Sol Casting. We service customers 3D drawings,aluminum die casting mold design, die casting, machining, surface treatment, packing and shipping all over the world.

Q2. Where is your factory?

A: Our factory located in No. 1, Bianjia, Yanshan Village, Yinjiang Town, Haishu District, Ningbo,Zhejiang Province, China

Q3. How to get a quotation?

A: Received the sample or 2D/3D drawings then we will provide the quotation.

Q4. What is your Payment terms?

A: Mold costs: 50% prepayment, balance after sample approval

Mass production: 30% prepayment, balance pay before delivery or as per discussion.

Q5.What is the lead time of mold and mass production?

A: Normally,it takes 30-45 days for bulk order and 30-60 days for the parts.Both product size and structural complexity affect manufacturing time.

Q6. How about the packing?

A: Standard or customized will both be available. B.How to guarantee the quality of your products?

1) Strict detection during production.

2) Strict sampling inspection on products before shipment and intact product packaging ensured.

Q7.What about your quality control?

A: Checking the raw material after they reach our factory-----Incoming quality control(IQC)

B: Checking the details before the production line operated

Have full inspection and routing inspection during mass production----In-process quality control(IPQC)

C:Checking the goods after they are finished----Final quality control(FQC)

D:Checking the goods after they are finished----Outgoing quality control(QC)

E.100% inspection and delivery before shipment.

Q8:Why choose us?

A.OEM & ODM

B.28 YEARS MANUFACTURE EXPERIENCE

C.OUR CLIENTS ARE IN OVER 38 DIFFERENT COUNTRIES ALL OVER THE WORLD.