Best processing performance

Perfect engineering design capability

Efficient team production method

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GS-Mach

-

Voltage:

-

380V 220V 3P

-

Dimension(L*W*H):

-

19*5*4.1M

-

Power (kW):

-

150

-

Weight:

-

28000 KG

-

Color:

-

gray and white

-

Easy operation:

-

easy

-

Marketing Type:

-

Ordinary Product

-

Name:

-

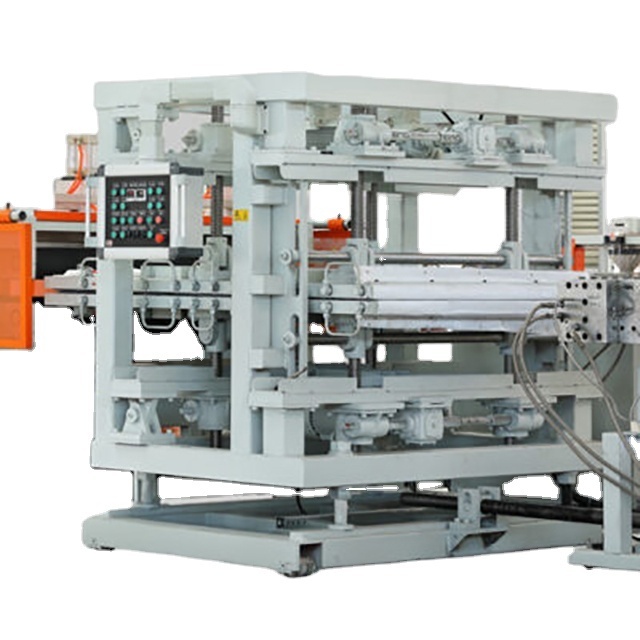

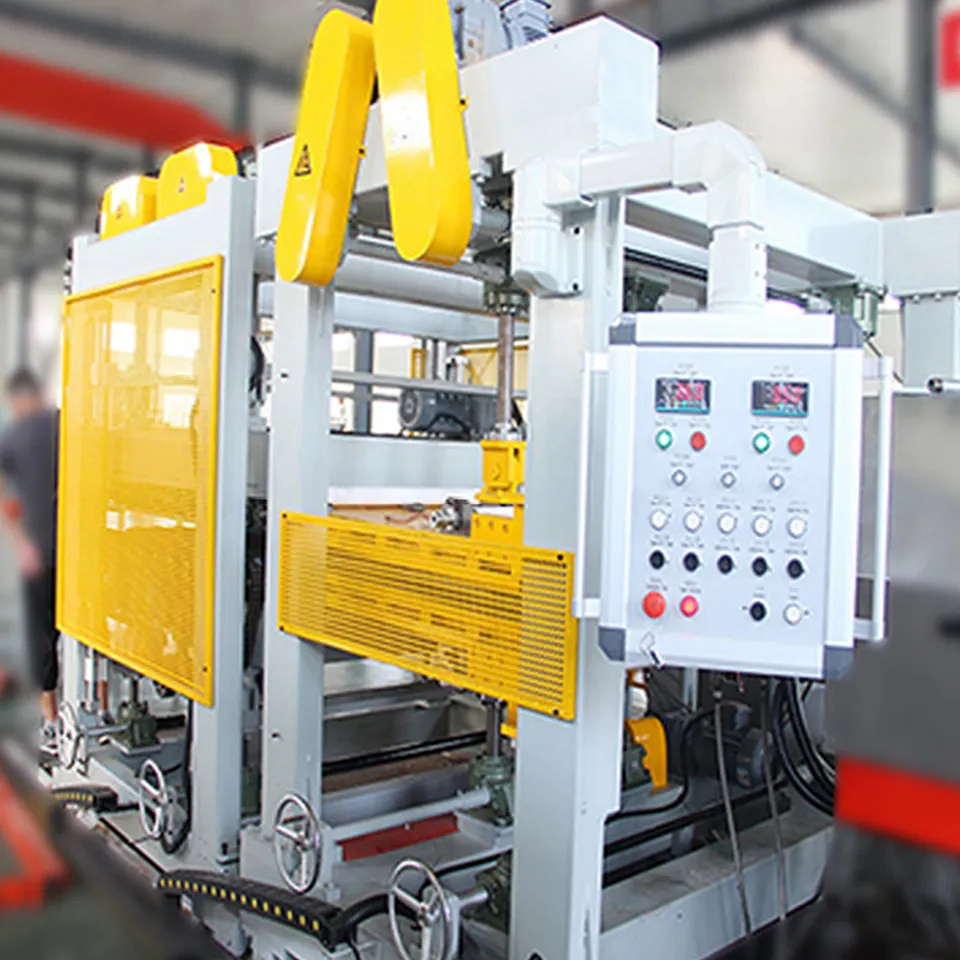

PLA foam board extrusion machine

-

Usage:

-

high-strength product

-

Temperature control:

-

Omron Brand

-

Product Application:

-

wall insulation, inverted roof insulation

-

Technology:

-

CO2 continue sheet extrusion

-

Product width:

-

900

-

Service:

-

Turn-Key project

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

28:1

-

Screw Speed (rpm):

-

1480 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GS-Mach

-

Voltage:

-

380V 220V 3P

-

Dimension(L*W*H):

-

19*5*4.1M

-

Power (kW):

-

150

-

Weight:

-

28000 KG

-

Color:

-

gray and white

-

Easy operation:

-

easy

-

Marketing Type:

-

Ordinary Product

-

Name:

-

PLA foam board extrusion machine

-

Usage:

-

high-strength product

-

Temperature control:

-

Omron Brand

-

Product Application:

-

wall insulation, inverted roof insulation

-

Technology:

-

CO2 continue sheet extrusion

-

Product width:

-

900

-

Service:

-

Turn-Key project

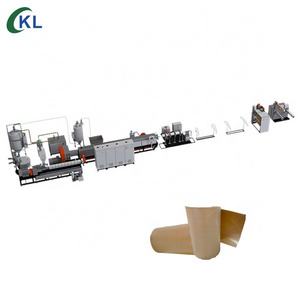

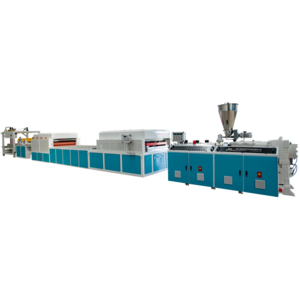

PP PE TPU PET PLA Supercritical CO2 continuous extrusion foaming production line

1.Multi-component weight reduction compound system

Fully automatic computer-controlled feeding system for various raw material ratios, with vacuum feeding to ensure stable conveying of raw materials.

A permanent magnet synchronous servo drive motor is used to combine the screw building block structure according to the processing process of the material.

Precise proportional control of the cooling system to ensure good cooling effect.

Supercritical CO2 blowing agent inhalation system

Adopt fully imported flow control system and unique three-stage booster injection system to maintain the stability of the foaming agent flow.

Adopt large diverter, long fan area head to build pressure extrusion, bi-directional electric adjustable device, low resistance system material proportional control, double-sided shaping.

Automatic fixed-length cutting, vertical and horizontal edge forming, automatic stacking, multi-point monitoring, automatic alarm, automatic packaging system, dust-free.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for

producing PET plastic containers and bottles in all shapes.

producing PET plastic containers and bottles in all shapes.

|

Gas type

|

co2

|

|

|

|

|||

|

Insert gas supplypressure

|

15(maximum 25MPa)

|

|

|

|

|||

|

Max. Amount ofinert gas added

|

10%

|

|

|

|

|||

|

Extrusion amount(when using PS)

|

20kg/h

|

20kg/h

|

20kg/h

|

20kg/h

|

|||

|

Extruder type

|

tandem

|

|

|

|

|||

|

First stage extruder(mixing)

|

25 twin-screw

|

40twin-screw

|

52twin-screw

|

65twin-screw

|

|||

|

Second stageextruder (cooling)

|

60 single-screw

|

90 single-screw

|

120 single-screw

|

150 single-screw

|

|||

|

Die system

|

circular die/Tdie

|

|

|

|

|||

|

Haul-off machine(cooling machine)

|

manufactured to production specifcations

|

|

|

|

|||

|

Winding machine.sizing

|

manufactured to production specifications

|

|

|

|

|||

Hot Searches