The forms

:

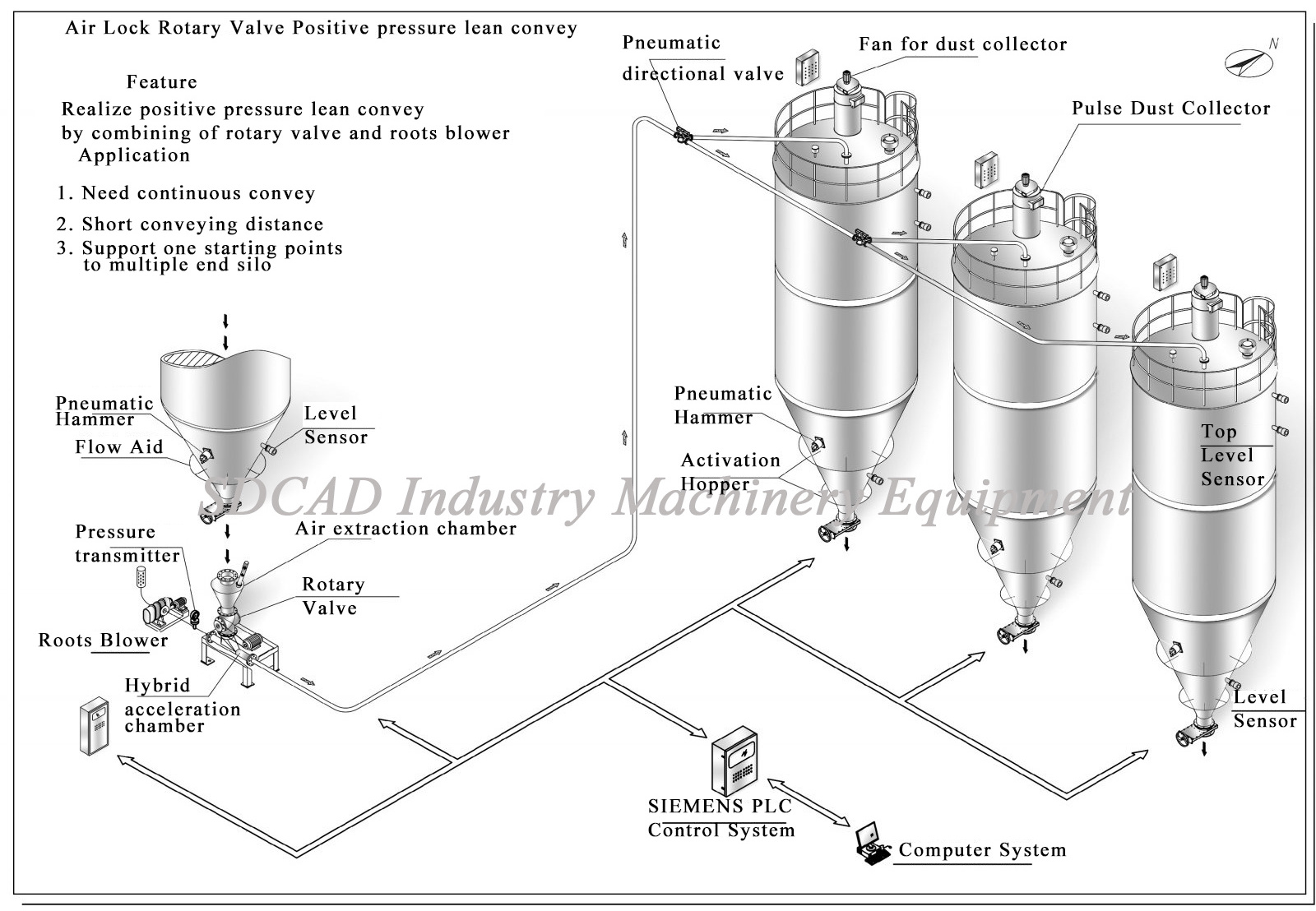

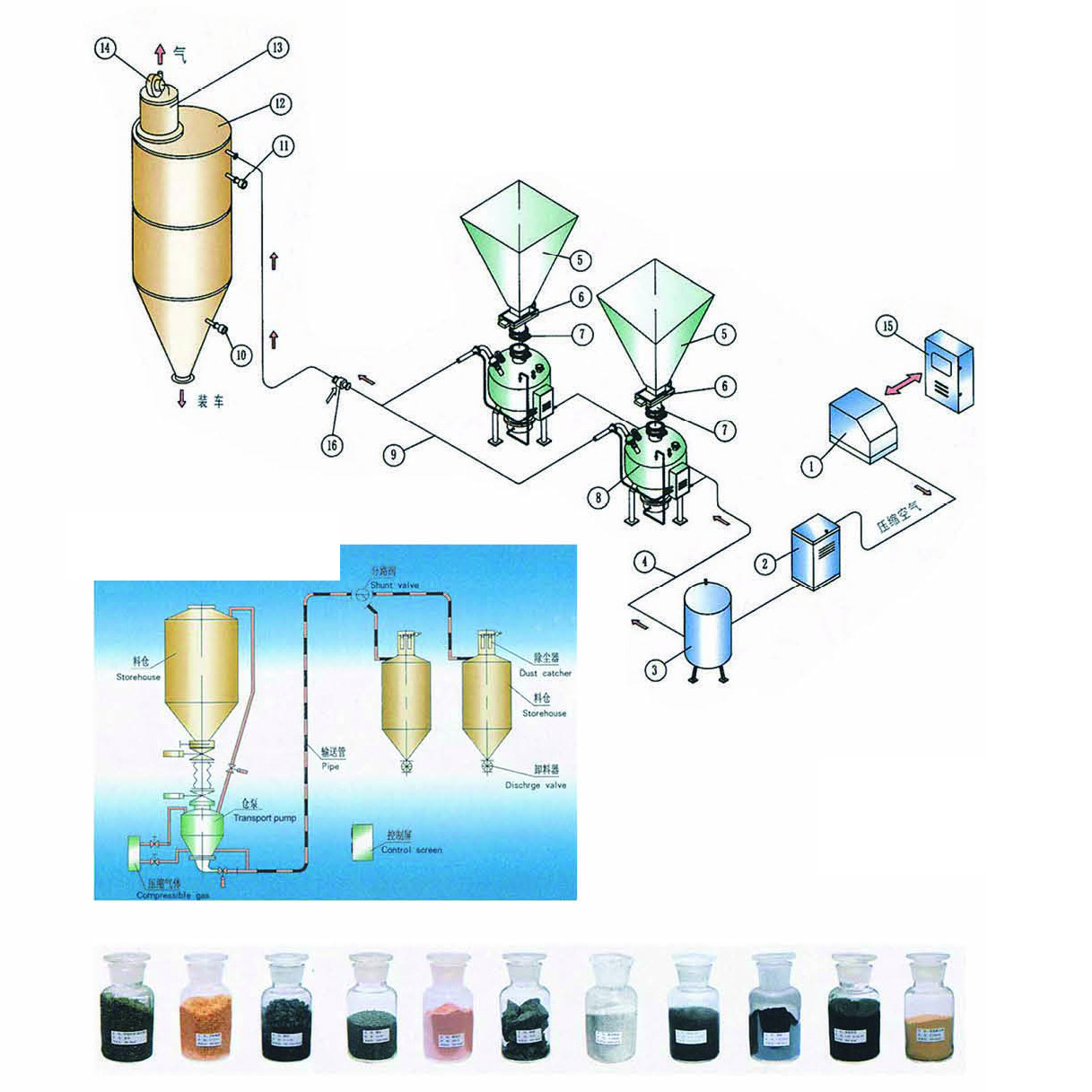

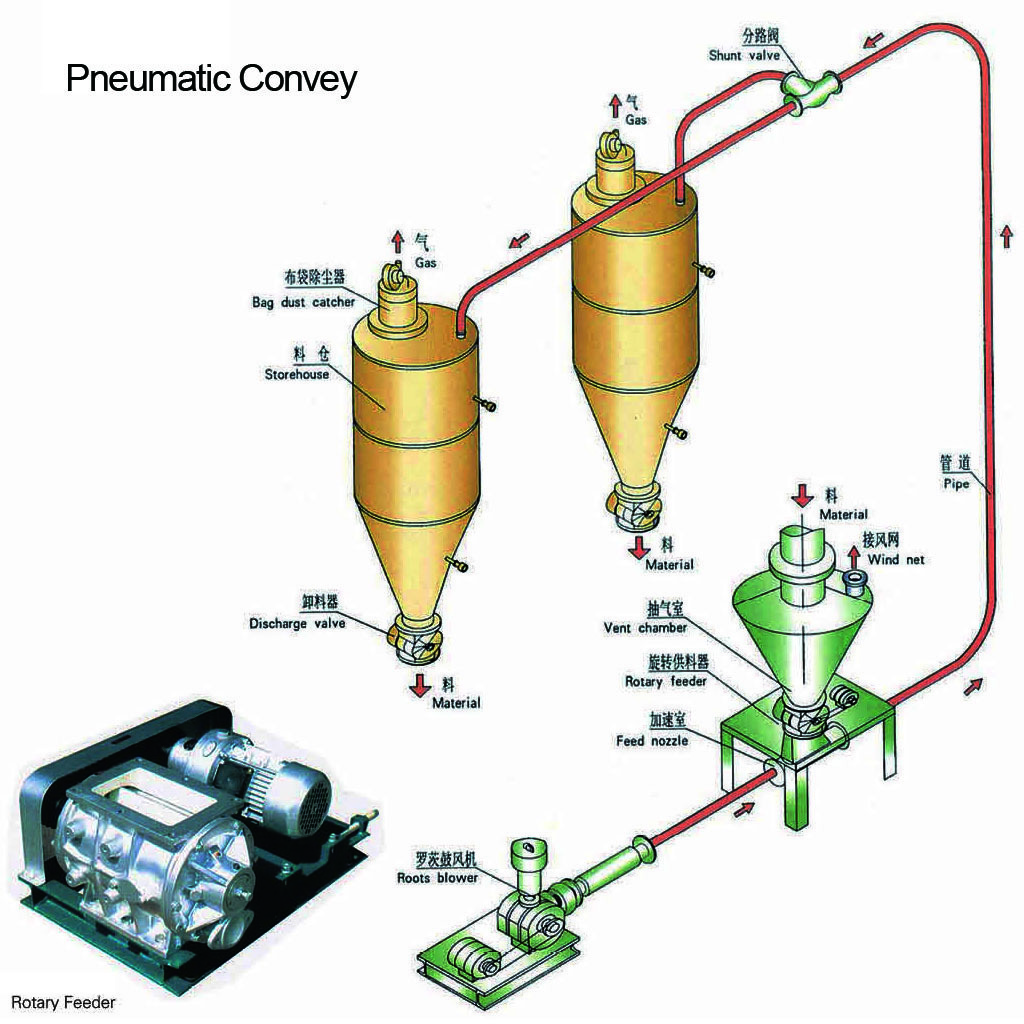

Pneumatic conveying are the dilute phase and dense phase.

The Type

:

Pneumatic conveying are pressure and vacuum

Application : Cement, fly ash, starch, sugar, salt, sand, plastic pellets, oats, polymers, lime, soda ash, plastic resin, plastic powder, dry milk, and feeds

Pneumatic Conveying System Full Process Solution Provider SDCAD