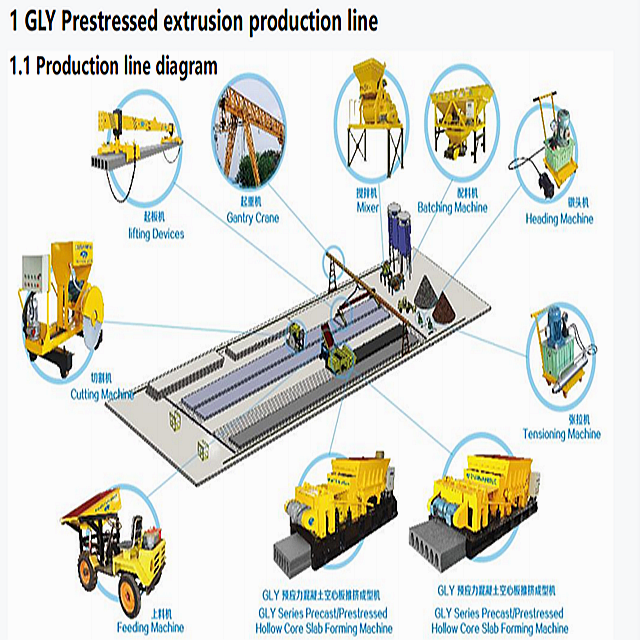

1. Low cost, high efficiency, the main machine comes with templates, raw materials using semi-dry concrete, through extrusion vibration molding, can be immediately shaped, than the traditional reversal template can save 60% of steel, compared to the die production can improve the efficiency of 3-5 times;

2. Simple operation, easy maintenance, the whole production line can be produced by 3-5 people;

3. Long service life, large friction parts in the machine cavity are made of hard alloy steel with high wear resistance, wear resistance and corrosion resistance;

4. Customized production, specifications and models can be customized according to the actual needs of the project;

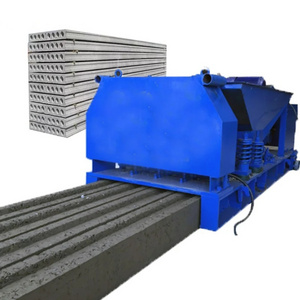

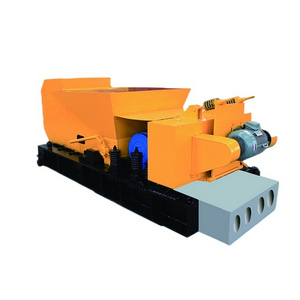

5. The member has high compactness and large span. The prestressed pretension method is adopted to prestretch the high-strength and low-relaxation steel strand, and the working principle of extrusion propulsion is used to manufacture the concrete member;

6. Arbitrary length cutting, according to the actual needs of engineering cutting length, not limited by modulus.

2. Simple operation, easy maintenance, the whole production line can be produced by 3-5 people;

3. Long service life, large friction parts in the machine cavity are made of hard alloy steel with high wear resistance, wear resistance and corrosion resistance;

4. Customized production, specifications and models can be customized according to the actual needs of the project;

5. The member has high compactness and large span. The prestressed pretension method is adopted to prestretch the high-strength and low-relaxation steel strand, and the working principle of extrusion propulsion is used to manufacture the concrete member;

6. Arbitrary length cutting, according to the actual needs of engineering cutting length, not limited by modulus.