- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Customized

-

Type:

-

Sheet Metal Stamping Mould

-

Material:

-

SKD11, SKD61, Cr12 MOV ect

-

Standard:

-

ISO9001-2005

-

Used:

-

Metal Stamping Industry

Quick Details

-

Shaping Mode:

-

Punching Mold

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LIHAO

-

Model Number:

-

Customized

-

Type:

-

Sheet Metal Stamping Mould

-

Material:

-

SKD11, SKD61, Cr12 MOV ect

-

Standard:

-

ISO9001-2005

-

Used:

-

Metal Stamping Industry

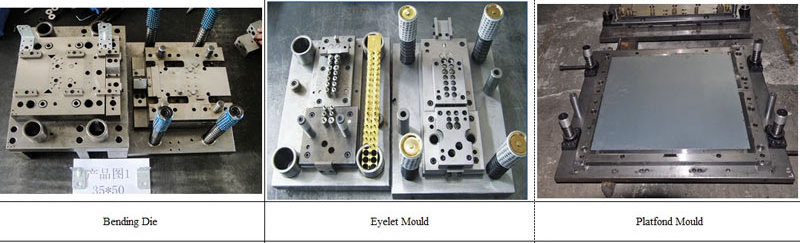

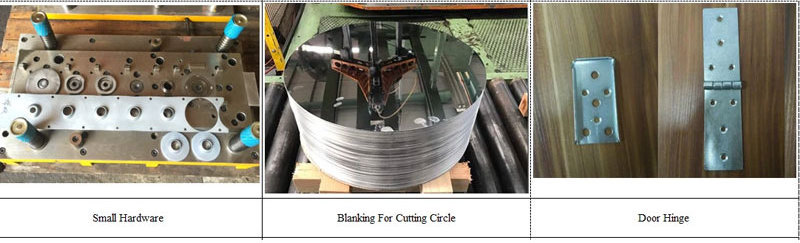

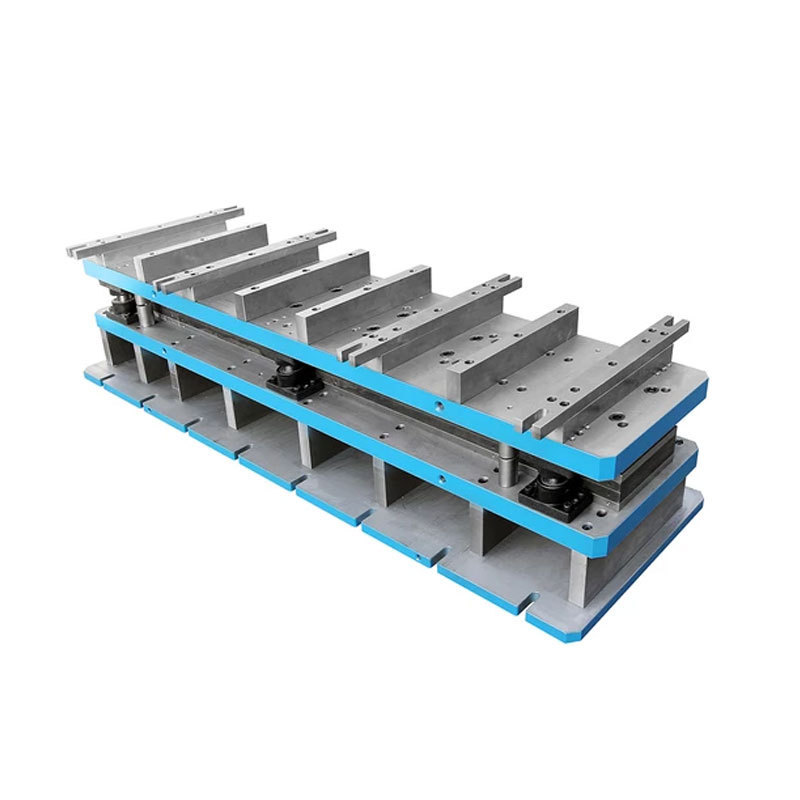

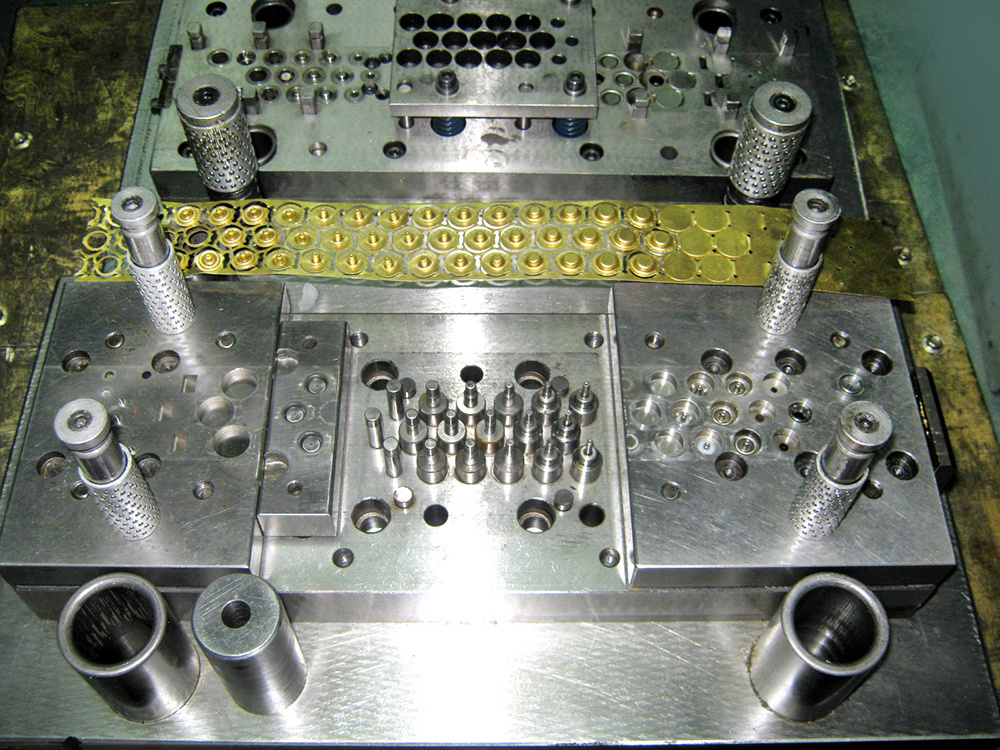

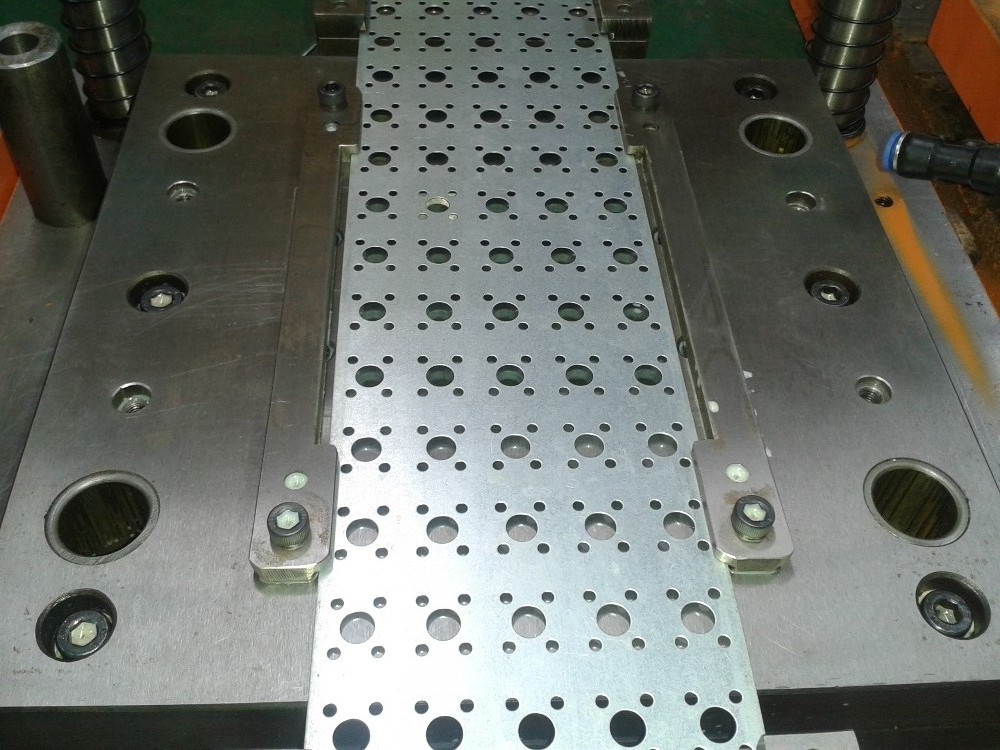

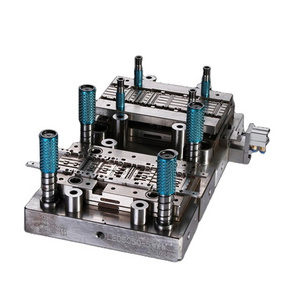

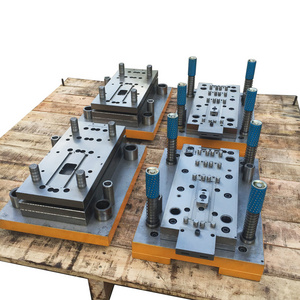

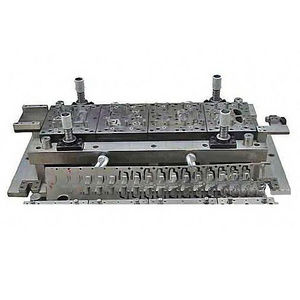

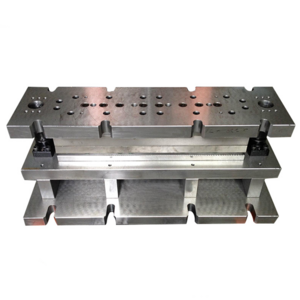

hot brass sheet coil progressive metal stamping die hydraulic press mold for sale

Specification:

|

Product Name |

Sheet metal progressive die |

|

Material |

SKD11, SKD61, Cr12 MOV ect |

|

Design Software |

Auto CAD, PRO/E, Solide works |

|

Standard |

ISO9001-2005 |

|

Mould Type |

Simple Blanking dies Progressive or Multi Cavity dies Compoun plus Progressive die Compound dies |

|

Sureface treament |

Zinc Plated, nickel plated, tin plate, brass plated, silver plated, gold plated ect. |

|

Lift time |

1,000,000-5,000,000 |

|

Used |

Metal Stamping Industry |

Functions:

1. use for process procedure more than 1 various products punching, various products widely used in mobile, tooling,

commodity, etc. industry production.

2. work with high speed press machine, punching SPM more than 200, production times 10 per day.As a result, avoid the

shape deviation when multiple dies and presses working at the same time by using general dies and presses to produce

big quantity products, better guarantee the product quality. Reduce facility requirement, as a result reduce factory space

requirement.

3. save material more than 10%.

4. use coil material and automatic feeder for production, greatly reduce labor intensity, save labor cost.

5. different model can be designed according to clients' product different shape, size, pattern, etc. requirement.