- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Mingyuan

-

Voltage:

-

220V/Customized

-

Power:

-

6KW

-

Dimension(L*W*H):

-

2800x1540x2000mm

-

Weight:

-

3400 kg

-

Marketing Type:

-

New Product 2024

-

Paper Cup Size:

-

4-16 0Z

-

Rated Speed:

-

130-150 pcs/min

-

Raw Material:

-

Single PE/double side PE:PLA coated paper cups,aluminum foil paper

Quick Details

-

Production Capacity:

-

150 pcs/min

-

Processing Type:

-

Paper cup forming

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Mingyuan

-

Voltage:

-

220V/Customized

-

Power:

-

6KW

-

Dimension(L*W*H):

-

2800x1540x2000mm

-

Weight:

-

3400 kg

-

Marketing Type:

-

New Product 2024

-

Paper Cup Size:

-

4-16 0Z

-

Rated Speed:

-

130-150 pcs/min

-

Raw Material:

-

Single PE/double side PE:PLA coated paper cups,aluminum foil paper

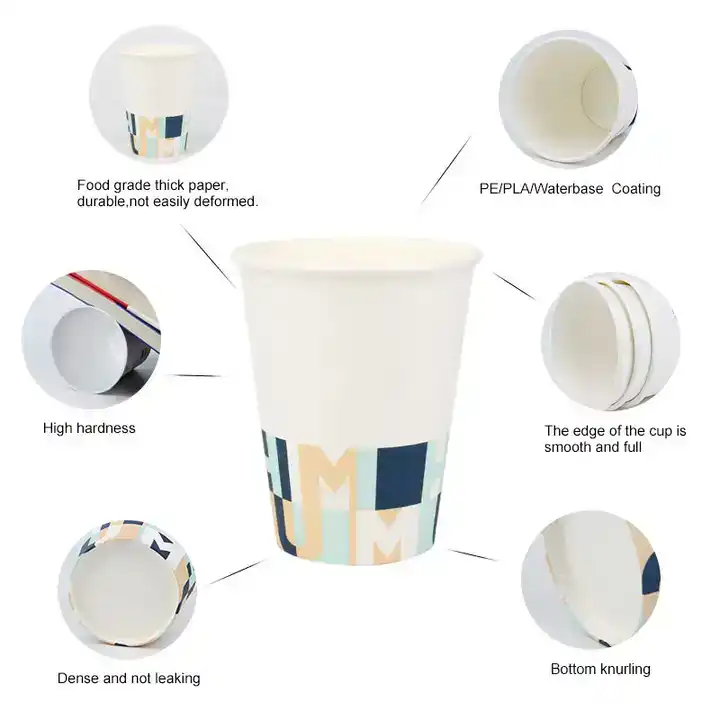

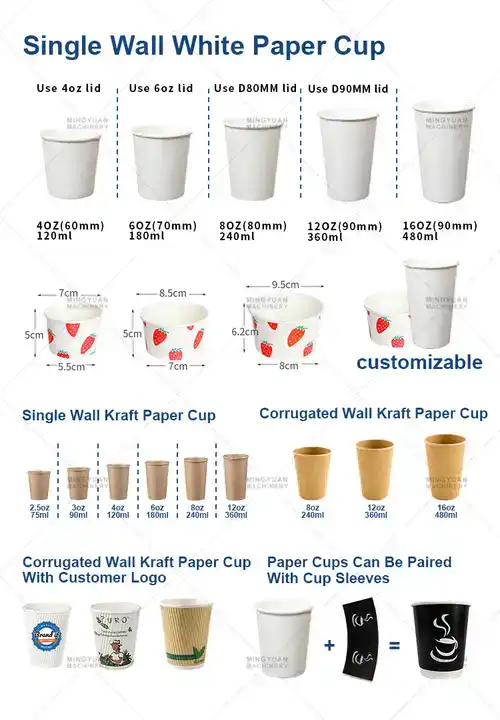

Product display

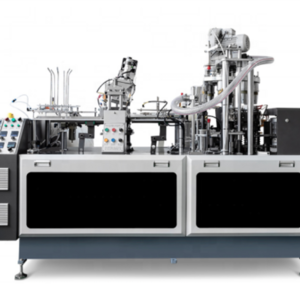

Product Parameter

|

Technical Parameters

|

|

|

|

|

||||

|

Model

|

MYC-120S

|

MYC-OCM12

|

MYC-DW100

|

|

||||

|

Paper cup size

|

4-16OZ

|

2-16OZ

|

4-22OZ(120-700ML)

|

|

||||

|

Speed

|

120-150 PCS/MIN

|

80-100/MIN

|

80-100/MIN

|

|

||||

|

Suitable Paper Weight

|

140-300gsm

|

140-350gsm

|

150-350gsm

|

|

||||

|

Suitable Paper WeightRaw material

|

Single PE/double side PE;PLA coated paper cups,aluminum foil paper

|

|

|

|

||||

|

Power Source

|

50/60HZ,380V/220V(better use 380V,3 Phase )or special Power requirement

|

|

|

|

||||

|

Total Weight

|

GWINW:3500KGS/3400KGS

|

GWINW: 1900KG/1750KG

|

GWINW:2000KGS/1900KGS

|

|

||||

|

Pack Size(L*W*H)

|

2800*1540*2000mm

|

2350*1110*2000mm

|

2450*1300*1900mm

|

|

||||

|

OEM ( Show Client Company Name in Machine Panel ) is welcome in our factory

|

|

|

|

|

||||

Cup design drawing/printing design

selling point of a product

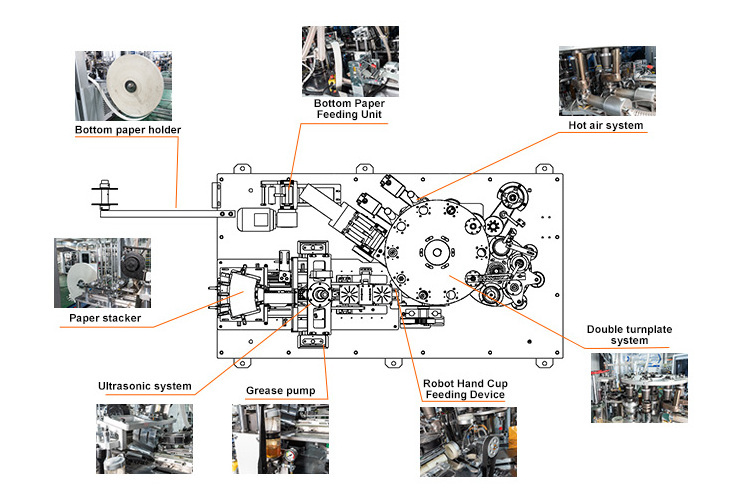

Touch Screen

It adopts PLC controller and touch screen (man -machine interface) allthe working parameters can be setup on the control panel which isconvenient for parameter settingand adjusting.(easy operate)

Double Turnplate Design

Top rim curling and bottom sealing inseparated turnplate which can greatly improve the machine stable

Robot Hand Cup Feeding Device

New design :4 in 1 rotatingrobot hand cup feeding device, so that the machine runsmore stable, higher speed

2 Pcs Oil Pump

the high speed machine includingSemi-fluid grease pump and silicone oil pump ,could keep the machineway moving spare running it more smooth and long time

Bottom Hot Air Heater

Double turnplate add 4 set hot blowing system,soft paper fan,paperbottom,2 times heating paper bottom when machine high speedrunning it make the finished paper cup quality more better not haveleakage issues

Bottom Paper Feeding and Punching Unit

The bottom feeding and punching are controlled by two pcs servomotors,which can ensure that the bottom feeding and cutting are moreaccurately,it can greatly save the bottom paper.

Expertise Answers

Our customers ask questions and

we do detailed videos to answer them all

. If you need video content you can send an inquiry to ask.

Company strength

Packaging shipping

FAQ

Q1. Are you trading company or manufacturer?

A:we are one of the leading manufacturer of the paper cup machine, Plastic lid machine, paper plate machine etc paper product machinery in China.

Q2. How will the machine be repaired if there are faults, and what is the warranty?

A:Our engineer team will send the operation video to guide you to solve the problem .if the spare parts is broken in the warranty period, we will send you the new replacement parts for free

Q3. What is the delivery time after the order ?

A:We have only half finished machine (no mould) in stock.The mould design is customized as each customer requirement The mould production costs 20 days,10 days for the installation.The delivery time is 30-35 days after the deposit payment

A:we are one of the leading manufacturer of the paper cup machine, Plastic lid machine, paper plate machine etc paper product machinery in China.

Q2. How will the machine be repaired if there are faults, and what is the warranty?

A:Our engineer team will send the operation video to guide you to solve the problem .if the spare parts is broken in the warranty period, we will send you the new replacement parts for free

Q3. What is the delivery time after the order ?

A:We have only half finished machine (no mould) in stock.The mould design is customized as each customer requirement The mould production costs 20 days,10 days for the installation.The delivery time is 30-35 days after the deposit payment

Q4.How can I install the machine and get training services in my country?

A:The machine will be finished installation and tested running perfectly before the delivery . You will get the complete machine which is finished installation. We will provide the full operation and training Videos to guide you to run the machine Anyone can install the machine and operate it easily.

Q5. What terms of payment you usually use?

A:T/T 30% deposit and 70% before machine loading, Western Union, L/C at sight.

A:The machine will be finished installation and tested running perfectly before the delivery . You will get the complete machine which is finished installation. We will provide the full operation and training Videos to guide you to run the machine Anyone can install the machine and operate it easily.

Q5. What terms of payment you usually use?

A:T/T 30% deposit and 70% before machine loading, Western Union, L/C at sight.

Hot Searches