- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

20 KG

-

Product name:

-

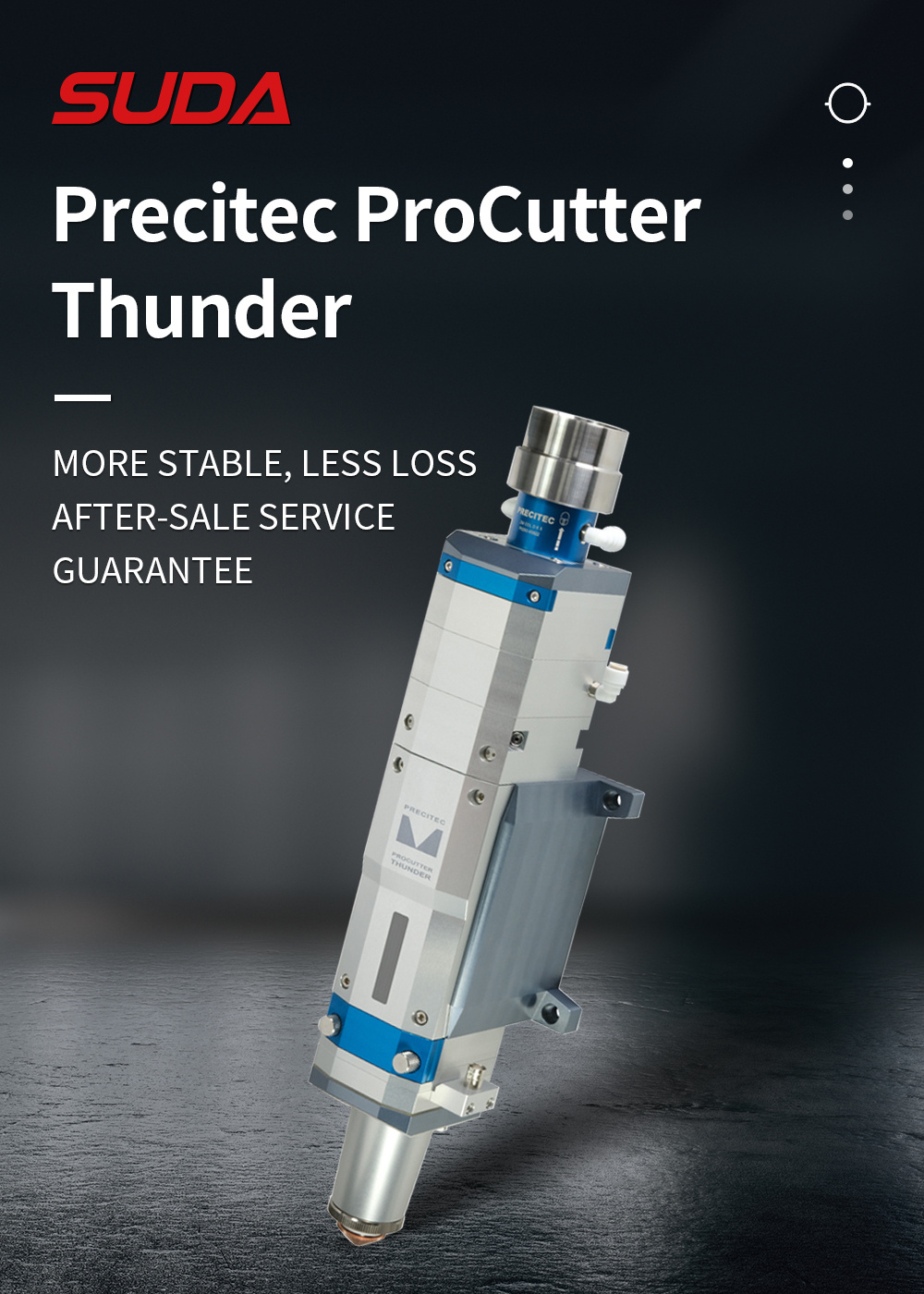

Precitec ProCutter Thunder Laser Cutting Head

-

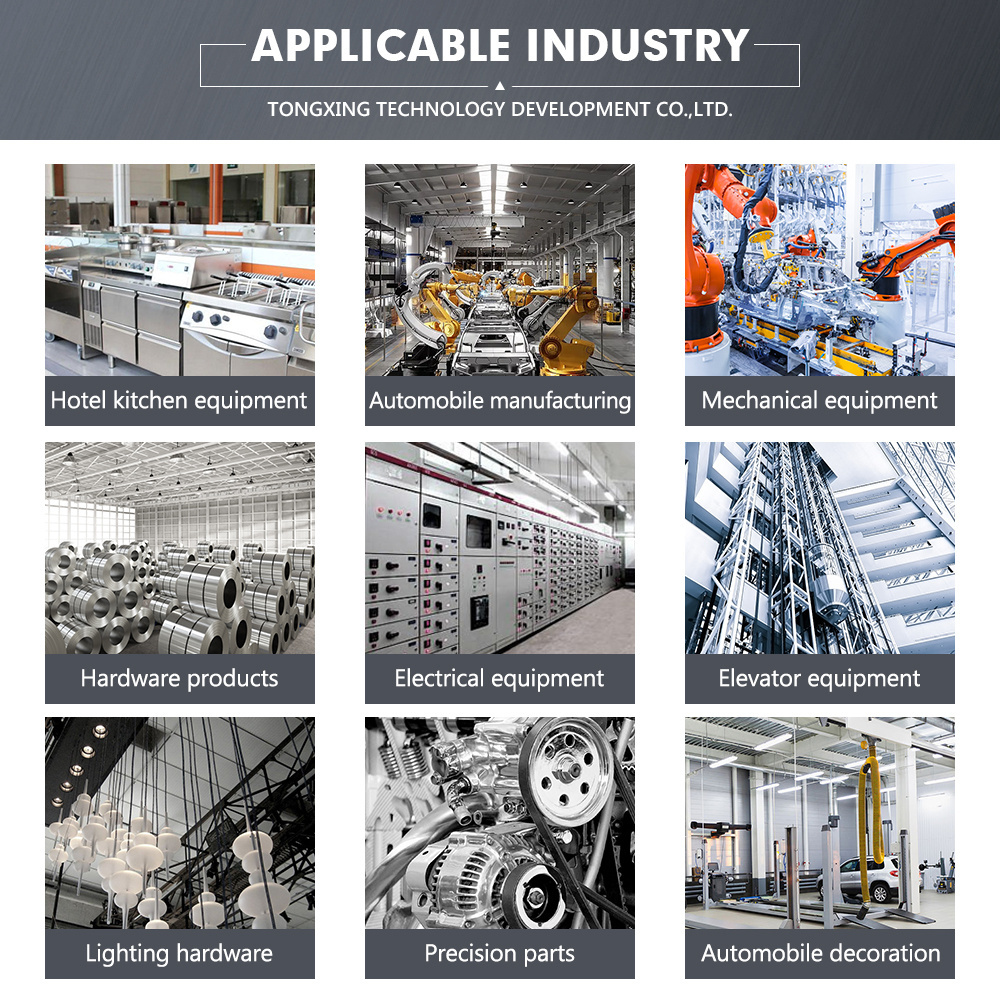

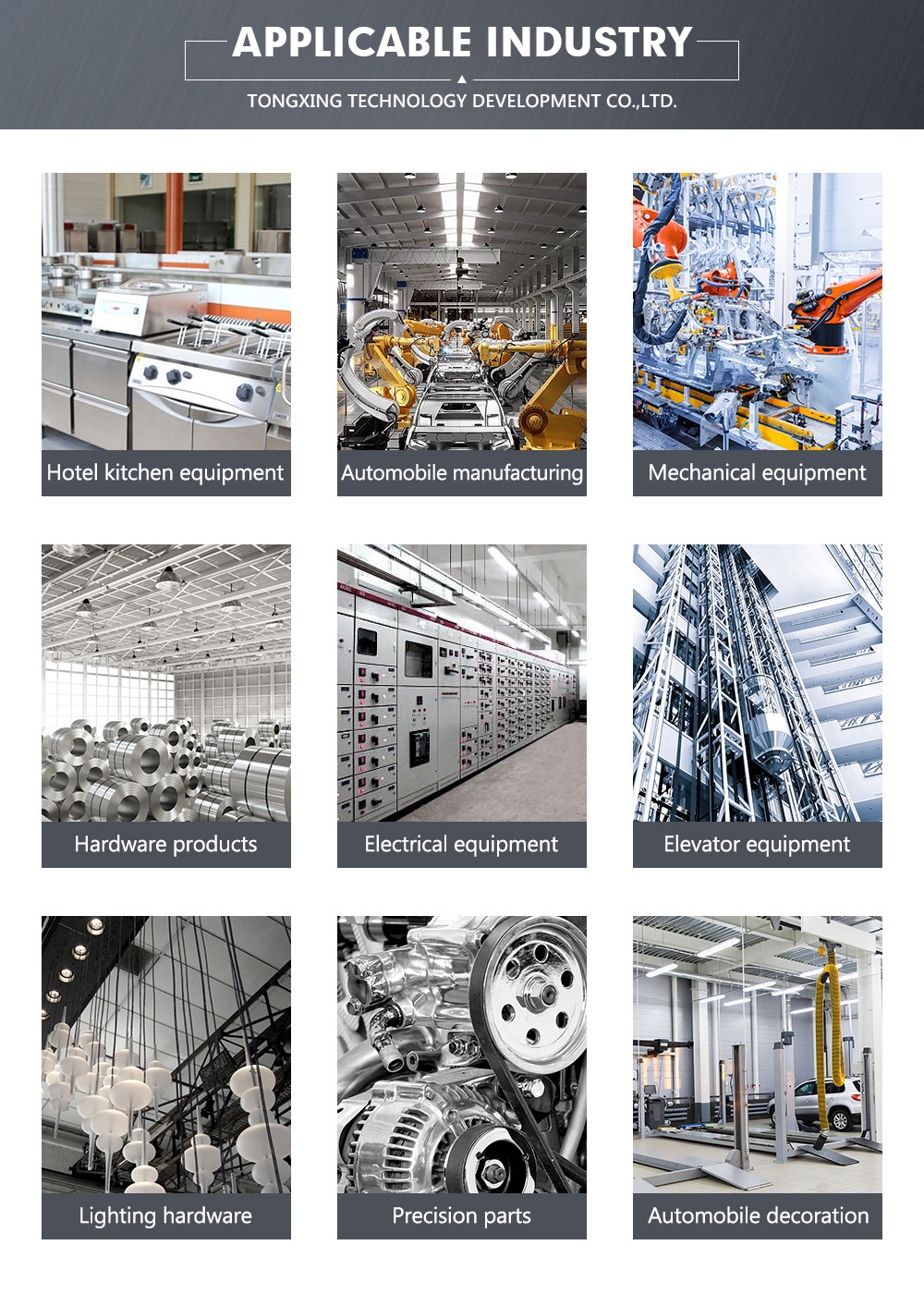

Application:

-

Industrial laser equipment

-

Laser type:

-

Fibre Laser

-

Focusing:

-

auto focus

-

Laser power:

-

6600W

-

Beam mode:

-

QBH

-

Wavelength::

-

1030-1090nm

-

Model:

-

Precitec ProCutter Thunder

Quick Details

-

Place of Origin:

-

Anhui, China

-

Spare Parts Type:

-

laser cutting head

-

Brand Name:

-

SUDA

-

Weight (KG):

-

20 KG

-

Product name:

-

Precitec ProCutter Thunder Laser Cutting Head

-

Application:

-

Industrial laser equipment

-

Laser type:

-

Fibre Laser

-

Focusing:

-

auto focus

-

Laser power:

-

6600W

-

Beam mode:

-

QBH

-

Wavelength::

-

1030-1090nm

-

Model:

-

Precitec ProCutter Thunder

|

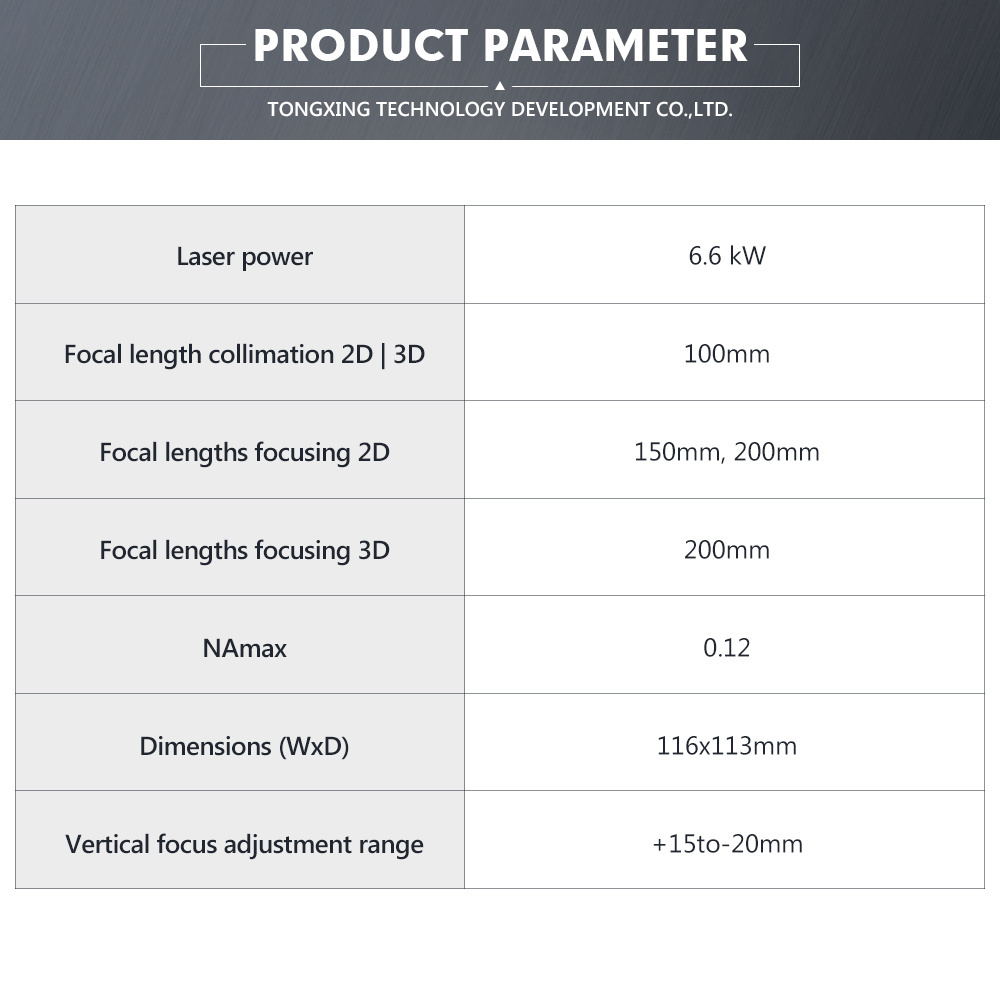

Model

|

ProCutter Thunder

|

|

max. laser power

|

6.6 kW

|

|

Focal length collimation 2D | 3D

|

100 mm

|

|

Focal lengths focusing 2D

|

150 mm, 200 mm

|

|

Focal lengths focusing 3D

|

200 mm

|

|

NAmax

|

0.12

|

|

Dimension (WxD)

|

116 x 113 mm

|

|

Vertical focus adjustment range

|

+15 to -20 mm

|

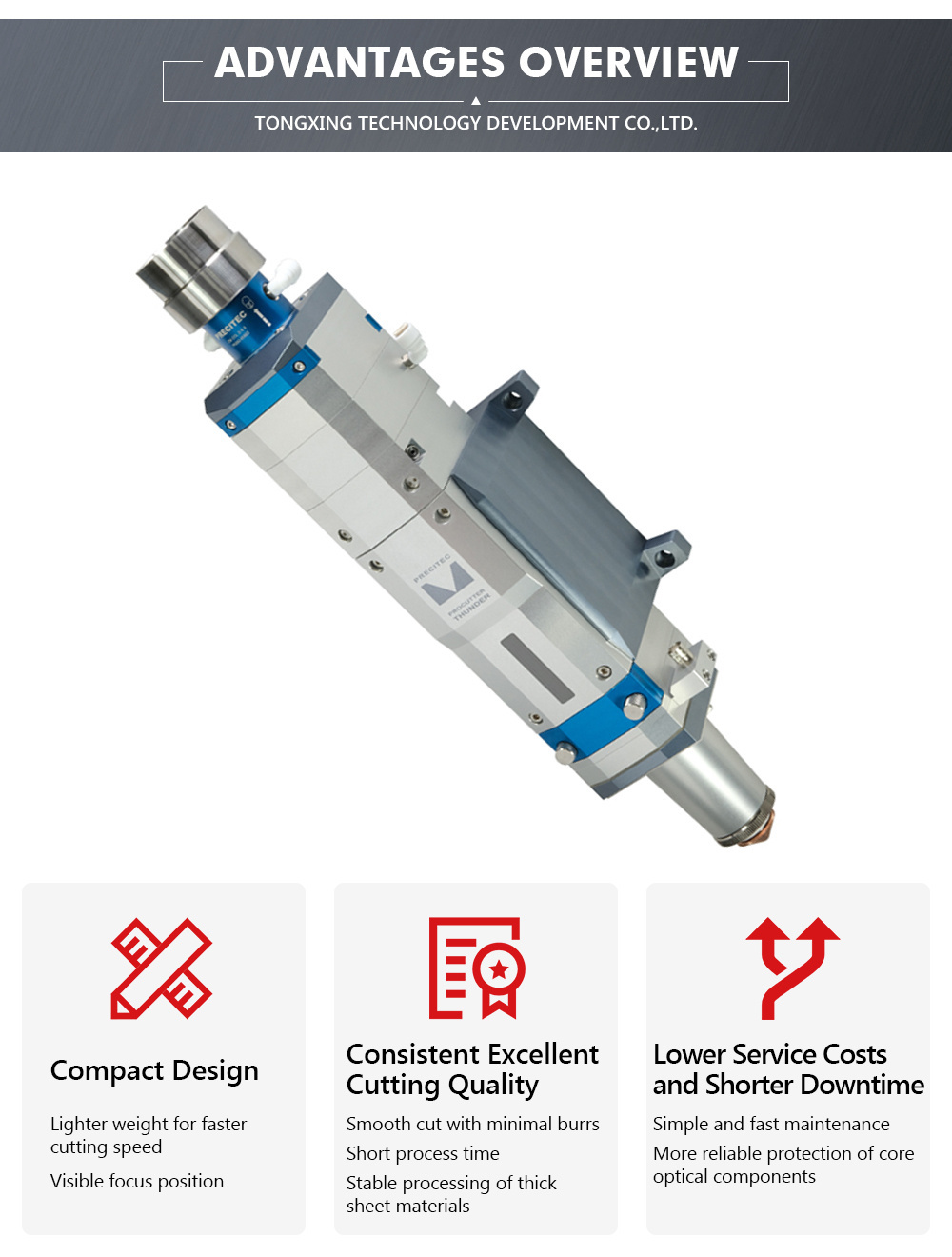

* High cutting-edge quality

The basis for smooth and right-angled cutting edges with minimal burr is the ultra-stable and drift-free distance sensor system. Even at very high accelerations, it guarantees a constant distance between the component and the head. Cooling of the head provides reproducible results in series production.

* Low service costs and less downtime

If the cutting head needs to be serviced, the design allows quick and easy access to the optics. A necessary change of these requires only half the time. Built-in protective glasses safeguard the valuable optics from the direction of the process zone and the fiber bushing, significantly extending service life.

Hot Searches