- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1%

-

Voltage:

-

380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

FillPack

-

Dimension(L*W*H):

-

2200X2100X2200MM

-

Weight:

-

3000 KG

-

Bottle type:

-

Tin can

-

Filling range:

-

180-900ML

-

Processing Types:

-

Filling and sealing

-

Material:

-

SUS304

-

Usage:

-

Beverage Filling Packaging

-

Suitable for:

-

Soft Drink Filling Line

-

Filling technology:

-

Isobaric filling

Quick Details

-

Machinery Capacity:

-

6000BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

Carbonated Beverage

-

Filling Accuracy:

-

±1%

-

Voltage:

-

380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

FillPack

-

Dimension(L*W*H):

-

2200X2100X2200MM

-

Weight:

-

3000 KG

-

Bottle type:

-

Tin can

-

Filling range:

-

180-900ML

-

Processing Types:

-

Filling and sealing

-

Material:

-

SUS304

-

Usage:

-

Beverage Filling Packaging

-

Suitable for:

-

Soft Drink Filling Line

-

Filling technology:

-

Isobaric filling

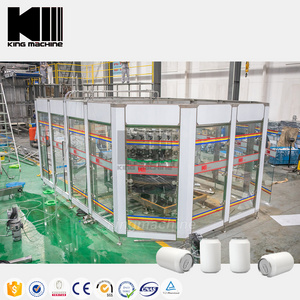

2 in 1 7000CPH Carbonated Beverage Soft Drink Tin Can Isobaric Filling and sealing Seamer Machine / Equipment / Device / Filler

Rotary magnet tin can washer is used for metal tin can washing. according to character of metal tin can and ordinary rotary bottle washer, use magnet to replace plastic bottle clamping, can be perfectly combined with high speed canning machine.

User can choose either water or air to wash the cans.

Capacity from 2000-15000CPH.

|

PLC

|

Mitsubishi Japan

|

1pc

|

|

Contactor

|

Schneider Germany

|

1pc

|

|

Air switch

|

Schneider Germany

|

1pc

|

|

stabilized voltage supply

|

MingWei TaiWan

|

1pc

|

|

Photo electricity

|

Autonics Korea

|

1pc

|

|

Touch screen

|

Easyview Taiwan

|

1pc

|

1. the machine is packed by wooden case.

2. The delivery date is within 30 days after payment.

500 / 1000 / 1500 / 2000 LPH Pure mineral Drinking water RO Reverse Osmosis purifying treatment machine / system

water purification system

2000BPH A-Z Soft / carbonated drink / cola / sparkling water mixing processing bottling filling labeling packing line

Customer's service:

1. FILL-PACK

company

can provide turn-key project for you, only you have any idea to start beverage factory plant.

2. FILL-PACK company have pro

fessio

nal design team, our engineer can draw bottle samples and flow chart ofworkshop for you .

3. FILL-PACK company give you the best quotation for all kinds of beverage production, only you can tell me whichkind of drink you want to product, what is your capacit

y(how many bottles one ho

ur) what is you bottle material, pet or glass,etc

After service:

1. We send the engineers to help installing, commissioning and training, the engineers start from our factory area.

2. We supply below necessary documents with the machine:

a. Machine layout

b. Electricity diagram

c. Machine certificate

d. General manual book/maintenance book

3. After one year guarantee, the seller provides payable spare parts and technician's VISITING maintenance service.