- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Eastman

-

Dimension(L*W*H):

-

depends

-

Weight:

-

800 KG

-

Product name:

-

Continuous Rod Mill

-

Color:

-

Customer Requirement

-

Quality:

-

High Level

-

Price:

-

Negotiable

-

Factory Visit:

-

Welcomed Warmly

-

Advantages:

-

High Efficiency Low Energy

-

Feature:

-

High Efficiency Low Cost

-

Installation:

-

Engineer's Guide

-

Grinding way:

-

Roller Grinding

-

After sale service:

-

Techniacal Support

Quick Details

-

Marketing Type:

-

Hot Product 2022

-

Capacity(t/h):

-

150kg/h

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Eastman

-

Dimension(L*W*H):

-

depends

-

Weight:

-

800 KG

-

Product name:

-

Continuous Rod Mill

-

Color:

-

Customer Requirement

-

Quality:

-

High Level

-

Price:

-

Negotiable

-

Factory Visit:

-

Welcomed Warmly

-

Advantages:

-

High Efficiency Low Energy

-

Feature:

-

High Efficiency Low Cost

-

Installation:

-

Engineer's Guide

-

Grinding way:

-

Roller Grinding

-

After sale service:

-

Techniacal Support

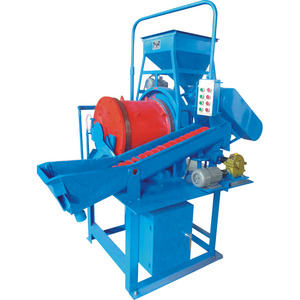

Product Introduction

Continuous Rod Mill

Φ420×600 Continuous Overflow Rod Mill is mainly consists of the feeding part, grinding part, discharging part, classification part and conveying part.

Working Principle

Consist of vibrating feeder with feed bin and volute feeder.After opening the gate of feed bin, the material is fed to the volute feeder evenly and continuously, and is fed to the drum with water by volute feeder.The feed quantity is regulated by opening size of the gate and rotation speed of the drum.

The volute feeder of the feeding system is a spiral shape spoon, by which the feed ore and return sand can be lifted and fed to the inside of drum.The feed volute is connected to the feed end of the drum and is covered in the volute feeder housing.The volute feeder housing can be disassembled and is easy for cleaning and inspection.

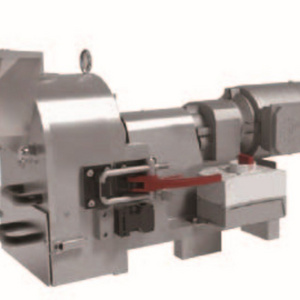

2.Grinding Part

The grinding part is a Φ420×600 lined with 6 corrugated manganese steel liner, the drum is supported by two pairs of rollers by two rims welded outside the drum.There is gear ring close to the feed part, and the drum is driven to rotate by means of bridge drive gear engagement.

3.Discharging Part

The ground product is discharged overflow from the discharging end, and flow into the spiral separator automatically by means of the gradient of discharging chute. There is hose connector welded on the upper end of discharge chute, which is connected with the water supply pipe by rubber hose.The water supply pipe is coupled with stopcock so as to adjust the quantity of water.There is a shield plugged outside the chute to avoid splash of discharge ore slurry.

4.Classification Part

The classification part is a φ150×1400mm spiral classifier. Make use of the inlet hole of discharging chute as one of the support point of one end,the whole spiral classifier can be turned to a certain degree of angle to achieve different inclination requirements.The other end is supported by screw rod, turn the hand wheel with sleeve nut to adjust the degree of slope,so as to control quantity of return sand and overflow fineness.

5.Conveying Part

The conveying part is a φ90×600mm spiral conveyor which connect to the spiral classifier and volute feeder housing, the sand from spiral classifier is evenly and continuously fed to the volute feeder housing.The classifier sand and raw ore are fed to the drum of rod mill by volute feeder. So the spiral classifier and rod mill constitute a closed grinding system, and continuous grinding is realized.The whole component is simple in structure, reasonable in sealing, reliable in driving and easy in installation and maintenance.

Water Supply and Electricity System

1.Water Supply System

There is a inlet water nozzle, after the water is supplied through this inlet water nozzle,the inlet water is divided into two parts, supplying water for both feeding part and discharging part, so as to satisfy the water requirements for working of the two parts.

During operation, on one hand, pay attention to check the water, check the sealing conditions of water pipe joints; on the other hand, due to the vertical structure of the two water inlet, so violet impact should be avoided which will result in damage to the pipelines. To ensure the effect of grinding and classification, constant pressure water tank can be used for water source.

2.Electricity System

The different parts of the mill are driven by independent motors and can be individually controlled.

Features

2.Closed circuit system enhance the grinding effection apparently;

3.Four motors drive independently and can be individually controlled;

4.Quality assurance, long service life.

Technical Parameter

|

Item

|

|

|

Unit

|

Specification

|

||

|

Mill Shell Size

|

|

|

mm

|

Φ420×600

|

||

|

Mill Speed

|

|

|

RPM

|

57

|

||

|

Mill Volume

|

|

|

L

|

80

|

||

|

Rod

Charge |

Φ35-Φ40

|

|

kg

|

45

|

||

|

|

Φ30

|

|

kg

|

60

|

||

|

|

Φ25

|

|

kg

|

50

|

||

|

Feed Size

|

|

|

mm

|

≤6

|

||

|

Discharge Size

|

|

|

mm

|

≤0.074

|

||

|

Feed Volume

|

|

|

cm³

|

700

|

||

|

Capacity

|

|

|

Kg/h

|

150

|

||

|

Motor |

|

Model

|

|

100L-6

|

||

|

|

|

Power

|

kw

|

2.2

|

||

|

|

|

Speed

|

RPM

|

920

|

||

|

Dimensions

|

|

|

mm

|

|

||

|

Weight

|

|

|

kg

|

800

|

||

|

Item

|

|

|

Unit

|

Specification

|

||

|

Spiral Diameter

|

|

|

mm

|

Φ150

|

||

|

Spiral Length

|

|

|

mm

|

1400

|

||

|

Overflow end width

|

|

|

mm

|

240

|

||

|

Tilt adjustment range

|

|

|

°

|

15°30’,22°

|

||

|

Maximum Return Sand Ratio

|

|

|

%

|

300

|

||

|

Spiral Speed

|

|

|

|

18,23,30

|

||

|

Motor

|

Model

|

|

|

YS7124-4

|

||

|

|

Power

|

|

kw

|

0.55

|

||

|

|

Speed

|

|

RPM

|

1400

|

||

|

Feed Size

|

|

|

mm

|

≤6

|

||

|

Discharge Size

|

|

|

mm

|

≤0.074

|

||

|

Feed Volume

|

|

|

cm³

|

700

|

||

|

Capacity

|

|

|

Kg/h

|

150

|

||

|

Motor |

|

Model

|

|

100L-6

|

||

|

|

|

Power

|

kw

|

1.5

|

||

|

|

|

Speed

|

RPM

|

920

|

||

|

Dimensions

|

|

|

mm

|

|

||

|

Weight

|

|

|

kg

|

800

|

||

|

Item

|

Unit

|

Specification

|

|

Bin volume

|

L

|

35

|

|

Vibratory Frequency

|

RPM

|

19

|

|

Feed Capacity

|

Kg/h

|

6-200

|

|

Motor

|

|

Share with spiral conveyor

|

|

Item

|

|

Unit

|

Specification

|

|

|

Spiral Size

|

|

mm

|

Φ90×600

|

|

|

Spiral Speed

|

|

RPM

|

38

|

|

|

Motor

|

Model

|

|

AO2-6314

|

|

|

|

Power

|

kw

|

0.12

|

|

|

|

Speed

|

RPM

|

1400

|

|

Packaging&Dilvery

●Ways Of Packing

● Shiping by sea/air freight

|

1.Small parts packed in the wooden cases.

|

or any way the customer requires.

|

|

2.Big parts packed by plastic membrane.

|

|

|

3.The whole big machine is loaded in the container.

|

|

Our Company

1.Inquiry and consulting support.

2.Ore sample testing support.

3.View our Factory.

4.Design Flowchart.

1.Training how to instal the machine, training how to use the machine.

2. 1 year warranty .

3.Engineers available to service machinery overseas.

FAQ

1.How is the quality of your products?(mining equipment/machine)

Answer: Our products are manufactured strictly according to national and international standard, and we will do a test on every machine before delivery.

2.Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description or promise we made before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before factory delivery, which is international trade practice; Finished product pictures will be provided to customers before delivery.

Contacts

If you are interested in our products, please don't hesitate to contact us. Could you tell me the following questions, so that I can give you a complete solution, including best Exw-works Price Quotation!

1. Which machine do you need? like gold washing machine, spiral chute, vibrating screen, Jig separator, Shaking table, etc.

2. What is your raw ore that you plan to process? like gold ore, diamond ore, tantalite or silica sand, etc.

3. What is the capacity you need? Like 10 tones per hour.

4. What is the feeding size to the machine? and what is the discharging-material size that you require?

Sincerely welcome to send your inquiry,you can get best quotation and professional service.

Hot Searches