- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TaiXiong

-

Model Number:

-

NdFeB

-

Product Name:

-

solar panel strong round cylinder ndfeb n42 magnet

-

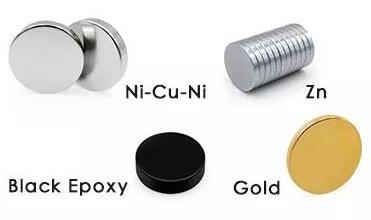

Coating:

-

Ni, Zn, Cr, Gold, Silver, Epoxy, Phosphating, etc

-

Processing Technique:

-

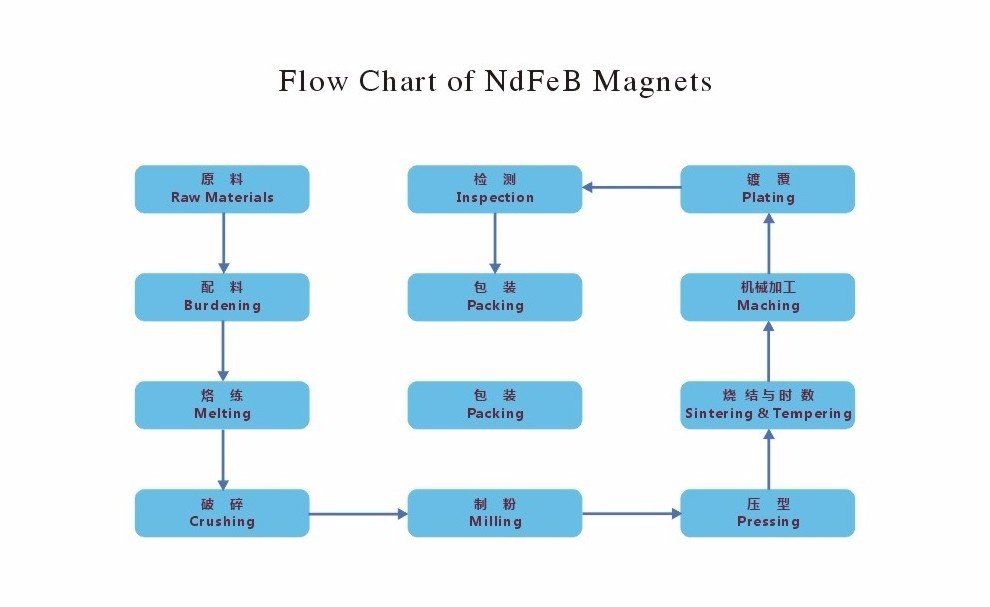

Sintering

-

Certification:

-

ISO9001:2008

Quick Details

-

Tolerance:

-

±1%

-

Grade:

-

NdFeb Magnet, Nd-Fe-B, N, M, H, SH, UH, EH, AH

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

TaiXiong

-

Model Number:

-

NdFeB

-

Product Name:

-

solar panel strong round cylinder ndfeb n42 magnet

-

Coating:

-

Ni, Zn, Cr, Gold, Silver, Epoxy, Phosphating, etc

-

Processing Technique:

-

Sintering

-

Certification:

-

ISO9001:2008

Product Description

|

Item Name

|

solar panel strong round cylinder ndfeb n42 magnet

|

|

|

|

|||

|

Material

|

Neodymium-Iron-Boron

|

|

|

|

|||

|

Coating

|

Nickel, Zinc, Chromium, Epoxy, Gold, Silver, Parylene, Everlube, Passivation, Copper, Chemical, PTFE and more.

|

|

|

|

|||

|

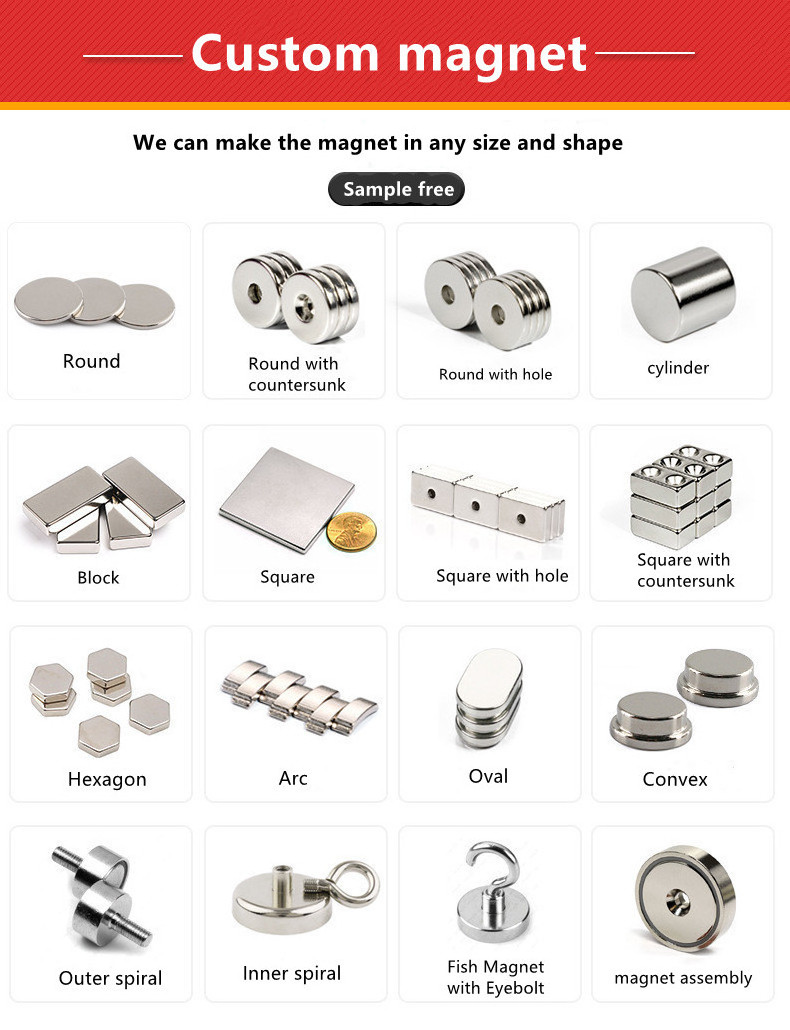

Shape

|

block, round, ring, arc - even highly complex forms. Virtually any shape of solar panel strong round cylinder ndfeb n42 magnet can be made to your requirements!

|

|

|

|

|||

|

Density

|

7.5-7.6 g/cm³

|

|

|

|

|||

|

Delivery date

|

7-10 days for common samples, 20-25 days for mass produciton

|

|

|

|

|||

|

Magnetic Grade

&

Working Temperature

|

Magnetic Grade

|

|

Working Temperature

|

|

|||

|

|

N35-N45

|

|

80 ℃(176

℉)

|

|

|||

|

|

N48-N52

|

|

60 ℃(160 ℉)

|

|

|||

|

|

35M-50M

|

|

100 ℃(212 ℉)

|

|

|||

|

|

33H-48H

|

|

120℃(248 ℉)

|

|

|||

|

|

33SH-45SH

|

|

150 ℃(302 ℉)

|

|

|||

|

|

30UH-40UH

|

|

180 ℃(356 ℉)

|

|

|||

|

|

28EH-38RH

|

|

200℃(392 ℉)

|

|

|||

|

|

28AH-33AH

|

|

220 ℃(428 ℉)

|

|

|||

Neodymium magnet

Sintered neodymium-iron-boron (NdFeB) magnets are the most powerful permanent magnets available today.NdFeB strong magnet has the characteristics of small size, light weight and strong magnetic properties, and is the best magnet to date with high resistance to demagnetization, high remanence and coercivity, and comes with a wide range of grades, sizes and shapes. The maximum operation temperature up to 220 degree centigrade.

We accept customized services:

1) Shape and Dimension Requirements; 2) Material and coating requirements; 3) Processing according to design drawings; 4)Requirements for Magnetization Direction; 5) Magnet Grade Requirements; 6) Surface treatment requirements (plating requirements)

Coating

Magnet Coating Types Display

Plating neodymium magnets is an important process to protect the magnet against corrosion. The typical coating for a neodymium magnet is Ni-Cu-Ni coating.Some other options for coating are zinc, tin, copper, epoxy, silver, gold and more.

Magnetization Direction

Common direction of magnetization showed in picture bellow:

1> Disc, cylinder and Ring shape magnet can be magnetized Axially or Diametrically.

2> Rectangle shape magnets can be magnetized through Thickness, Length or Width.

3> Arc shape magnets can be magnetized Diametrically, through Width or Thickness.

Special direction of magnetization can be customized as required.

Application

1).

Electronics

– Sensors, hard disk drives, sophisticated switches, electro-mechanical devices etc.;

2).

Auto Industry

– DC motors (hybrid and electric), small high-performance motors, power steering;

3).

Medical

– MRI equipment and scanners;

4).

Clean Tech Energy

– Water flow enhancement, wind turbines;

5).

Magnetic Separators

– Used for recycling, food and liquids QC, waste removal;

6).

Magnetic Bearing

– Used for highly sensitive and delicate procedures in various heavy industries.

Packing & Delivery

1.White inner box.

2.Suitable carton size.

3.Anti-magnetized packaging.

4.We will suggest the best solution of shipment for your reference according to order quantityes.

Why Choose Us

Our company is a specialized supplier and manufacturer of permanent magnets and magnetic assemblies, magnetic motors, etc. Our products include NdFeB magnet, rubber magnet, SmCo magnet, alnico magnet, ferrite magnet, educational magnet, magnetic separator, pot magnet,magnetic lifter, lifting magnet, magnetic badge holder. With over 10 years' history, our factory has established and implemented a quality management system in conformity with ISO9001:2008 standard. All magnet materials and coatings meet the standards of SGS and RoHS. Our factory has passed ISO9000 and TS16949 certificates. Our factory makes high quality magnet to meet our customers' different requirements. Our products sell well in over 50 countries and regions all over the world such as America, the EU, the Middle East, Hong Kong, etc. Our factory has adopted the most advanced technology (thin strip alloy and hydrogen decrepitation).

FAQ

Q1: Could I get samples?

A: Samples are available and free.

Q2: How about your delivery date?

A: 3-7 days for samples and 15-20 days for mass production.

Q3: Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q4: What is the usual payment method?

A: T/T, Paypal, L/C, VISA, e-Checking,Western Union.

Q5: How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Hot Searches