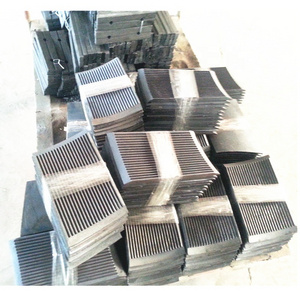

For the characteristics of rigid PVC material, we've designed unique grinding discs.

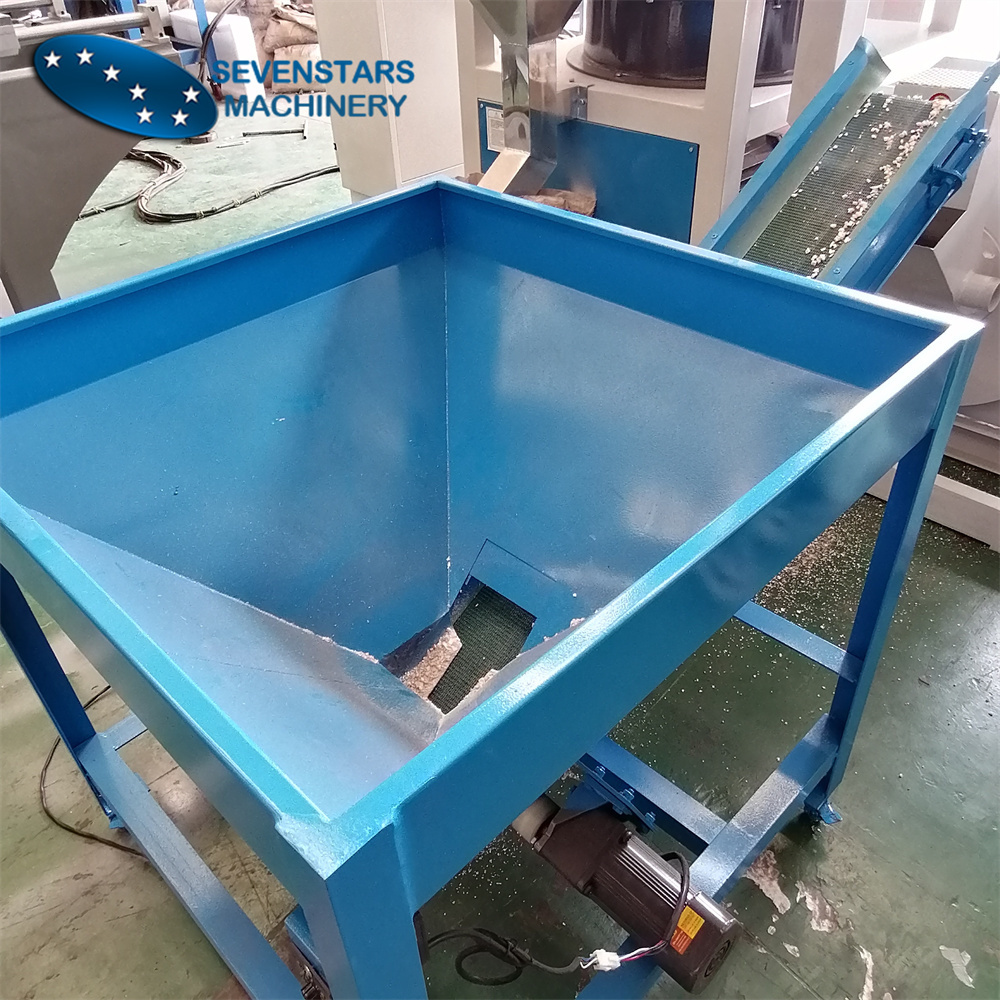

Generally, the size of raw material don't surpass 12 mm. Final product size is in general between 20-80 mesh. The mesh size is adjustable.

Its new tool structure improves the output and overcomes the abrasion resistance of the tool.

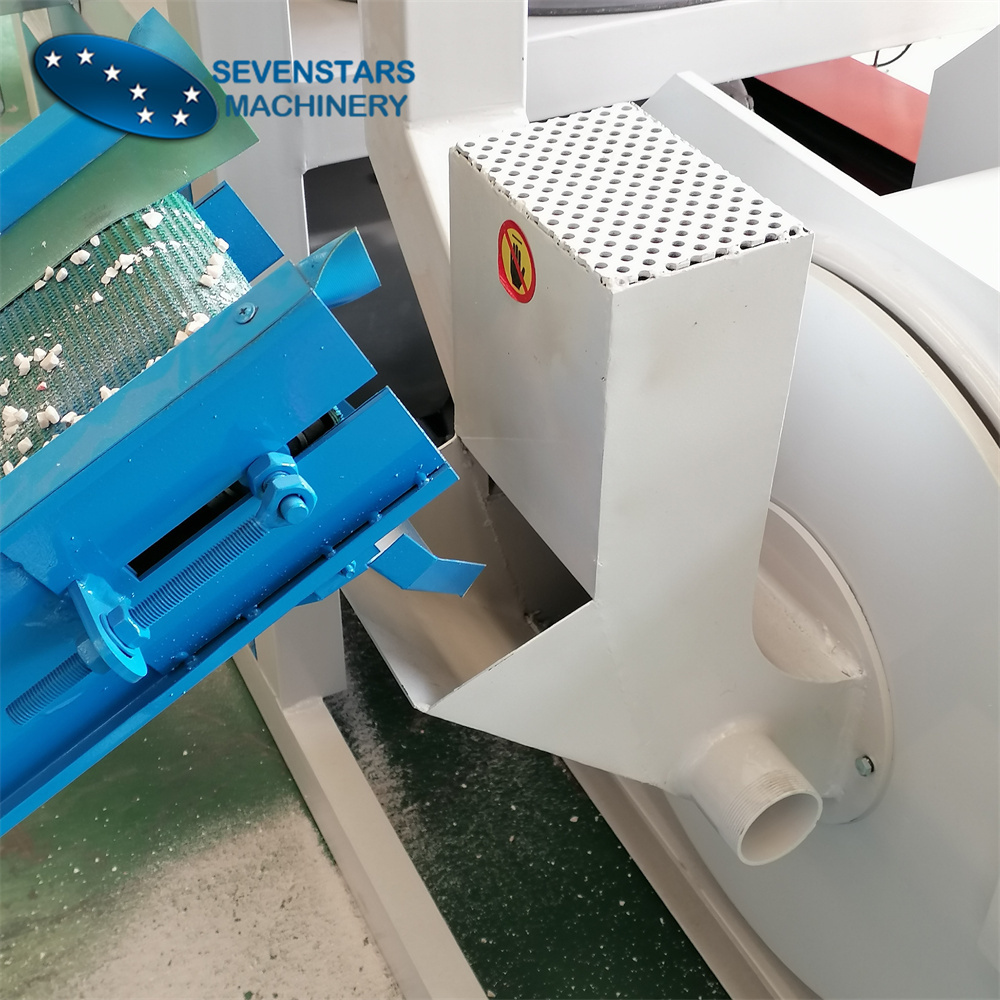

The cooling system of the plastic mill adopts a combination of air and water cooling.