- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Local Requirement

-

Power:

-

85-365 Kw

-

Dimension(L*W*H):

-

18*8*9 m

-

Weight:

-

120 kg

-

Features:

-

Advacend Technology

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

fineness of powder:

-

adjustable

-

price:

-

competitive

-

Raw material:

-

Natural Gypsum Ore

-

Technology:

-

Rotary Calciner

-

Fuel:

-

Oil Gas Coal

-

Type:

-

Full-automatic

-

Working condition:

-

Stable and safe

-

Advantages:

-

High Productivity

-

Experience:

-

Over 20 years

Quick Details

-

Application:

-

Gypsum Powder Production

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dafu

-

Voltage:

-

Local Requirement

-

Power:

-

85-365 Kw

-

Dimension(L*W*H):

-

18*8*9 m

-

Weight:

-

120 kg

-

Features:

-

Advacend Technology

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

fineness of powder:

-

adjustable

-

price:

-

competitive

-

Raw material:

-

Natural Gypsum Ore

-

Technology:

-

Rotary Calciner

-

Fuel:

-

Oil Gas Coal

-

Type:

-

Full-automatic

-

Working condition:

-

Stable and safe

-

Advantages:

-

High Productivity

-

Experience:

-

Over 20 years

High effective alpha gypsum powder plant, Customized gypsum powder production line

| Introduction of gypsum powder production line |

|

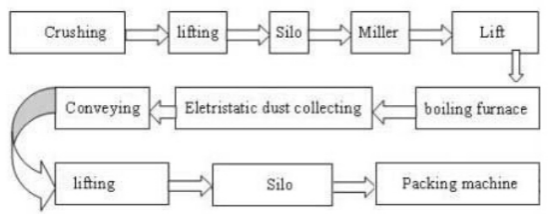

Gypsum powder production line Low investment, short construction period, and fast standard and achievement achieved, the 1000 tpd new dry process cement production carries out the overall design concept which combines raw material preparation and clinker calcining together. Raw material preparation uses vertical mill, while the waste gas from kiln can be reused by the vertical mill for drying raw material. Thus it fully saves a lot of energy. This production line runs well and brings good economic benefit for the enterprises. Working theory 1.the main part of boiling furnace is composed of thin and dense radiator pipes , which is filled with conduction oil to release the heat to the inside of the furnace . 2.Equipped at the bottom of the furnace, the roots blower makes the powder inside the furnace into the boiled state . The powder material, backed and dehydrated with crystallization water at certain temperature flow out through the outlet automatically. 3.The gypsum powder produced by this procedure has stable quality and well controlled crystallization water rate, initial and final set time . 4.Further more, by using dry electrostatic cleaner , the equipment has over 95% dust collectionefficiency and eliminate the dust pollution. |

Flow chart of Gypsum Powder Production Line :

| Picture of natural gypsum powder production line |

|

|

|

Advantages of gypsum powder production line:

|

|

1. We have built many lines for oversea company, such as Columbia, Uzbekistan , Mexico, Italy, USA, etc; 2. Use hot oil or natural gas technology; 3. Supply top-quality machines and good after-sale service; 4. Can design all capacities you want; 5. Fully automatic operation; 6. Save evergy. |

|

Why choose our product ?

|

|

1) We are professional manufacturer and exporter with our own factory; 2) We have our own professionals and technicians to handle development, design, production, sales and service; 3) Our products have passed the CE Certification and ISO9001: 2008. 4) We use the real steel structure. 5) Our customers are all over the world, received very well feedback from them. 6) Excellent mixing performance; 7) The whole set of machine can be auto-operated by PLC; 8) Perfect after-sale service; 9) High quality and reasonable price 10) 12 months guarantee; 11) Have a professional, respectful, and effectively cooperate team; 12) The quality of our machineries is stability for we have about 10 years’ experience. 13) We combine our experience with European technology to improve our machinery quality. |

| Our services |

|

Pre-sales Service

1.Offering comprehensive technical and business consultation services;

Service on Sale

1.Providing initiative and enthusiastic service;

After-sale service 1. One year free warranty 2. Technician-online support 3. Email to solve 4. Engineers available to service machinery overseas |