- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380 V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

PRINTYOUNG

-

Dimension(L*W*H):

-

17500 * 6900 * 3700 mm

-

Weight:

-

15000 KG

-

Certification:

-

CE

-

Marketing Type:

-

Other

-

Paper Kind:

-

Copy paper , coated paper

-

Working Speed:

-

9 - 11 reams/min

-

Paper Thickness:

-

60 - 500 gsm

-

Thickness of Wrapping Paper:

-

100 - 180 gsm

-

Diameter of Wrapping Paper:

-

Max. 1000 mm

-

Core Diameter of Wrapping Paper:

-

3

-

Kind of Wrapping Paper:

-

Laminated paper , kraft paper

-

Maximum Size of Bag:

-

650 - 1400 mm

-

Minimum Size of Bag:

-

600 - 1000 mm

-

Thickness of Ream:

-

25 mm - 60 mm

Quick Details

-

Packaging Type:

-

Bags

-

Packaging Material:

-

Paper

-

Driven Type:

-

Electric

-

Voltage:

-

380 V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

PRINTYOUNG

-

Dimension(L*W*H):

-

17500 * 6900 * 3700 mm

-

Weight:

-

15000 KG

-

Certification:

-

CE

-

Marketing Type:

-

Other

-

Paper Kind:

-

Copy paper , coated paper

-

Working Speed:

-

9 - 11 reams/min

-

Paper Thickness:

-

60 - 500 gsm

-

Thickness of Wrapping Paper:

-

100 - 180 gsm

-

Diameter of Wrapping Paper:

-

Max. 1000 mm

-

Core Diameter of Wrapping Paper:

-

3

-

Kind of Wrapping Paper:

-

Laminated paper , kraft paper

-

Maximum Size of Bag:

-

650 - 1400 mm

-

Minimum Size of Bag:

-

600 - 1000 mm

-

Thickness of Ream:

-

25 mm - 60 mm

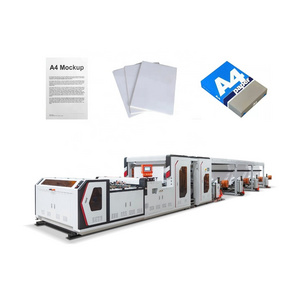

PRY-1400 Ream Paper Wrapping Machine

Technical Parameters

|

PRY-1400 Ream Paper Wrapping Machine

|

|

|

|

Paper Kind

|

Copy paper , coated paper

|

|

|

Automation

|

Automatic

|

|

|

Working Speed

|

9 - 11 reams/min

|

|

|

Paper Thickness

|

60 - 500 gsm

|

|

|

Thickness of Wrapping Paper

|

100 - 180 gsm

|

|

|

Diameter of Wrapping Paper

|

Max. 1000 mm

|

|

|

Core Diameter of Wrapping Paper

|

3”

|

|

|

Kind of Wrapping Paper

|

Laminated paper , kraft paper

|

|

|

Maximum Size of Bag

|

650 - 1400 mm

|

|

|

Minimum Size of Bag

|

600 - 1000 mm

|

|

|

Thickness of Ream

|

25 mm - 60 mm

|

|

|

Weight of Ream

|

15 - 60 kg

|

|

|

Overall Size of Machine

|

17500 × 6900 × 3700 mm

|

|

|

Gross Power

|

35 kw

|

|

|

Machine Weight

|

15 T

|

|

Configuration

Paper Delivery Section

Operator only needs to push the paper ream forward 100mm,it will be delivered to the next packaging process automatically,until

to the packaging completed.

to the packaging completed.

Oberse Packaging Section of Paper Ream

With the special packing device,the packaging are neat in order before and after the paper ream,no packaging blind angle,and

the special vacuum unit is conducive to packing tightness.

the special vacuum unit is conducive to packing tightness.

Bilateral Packaging Section of Paper Ream

With the fixed sliding folding and closing device,the two sides of paper reams are wrapped accurately,when angle folding,with

the special device to press the paper,in order to avoid packaging wrinkle.During delivery process,the both sides of the paper ream sealed well by hotmelt glue.

the special device to press the paper,in order to avoid packaging wrinkle.During delivery process,the both sides of the paper ream sealed well by hotmelt glue.

Paper Collecting Section

Paper collecting section adopted special endless conveyor belt.

The control system can accurately control the hoisting height of lifting table according to the thickness of the paper reams,so that the paper ream stacking in order can be ensured.

The control system can accurately control the hoisting height of lifting table according to the thickness of the paper reams,so that the paper ream stacking in order can be ensured.

Main Composition

|

Unwind Unit

|

|

|

|

Wrapping Paper

|

Kraft paper , printed paper

|

|

|

Unwind Unit

|

1 set of unwinder

|

|

|

Paper Reel Lifting

|

Fixed

|

|

|

Brake of Paper Reel

|

Magnetic powder brake

|

|

|

Dia. of Paper Reel

|

1000 mm

|

|

|

Height of Paper Reel

|

1.8 m

|

|

|

Dia. of Air Shaft

|

3 inch

|

|

|

Stand of Core

|

Unwinding trolley , fixed frame on both sides

|

|

|

Cutting Unit

|

|

|

|

Cutting Method

|

Photoelectric control

|

|

|

Cross Sheeting Knife

|

Upper and bottom knife fixed

|

|

|

Cutting Length Control

|

Photoelectric Control

|

|

|

Cutting Width

|

The width is wrapping paper is decided by wrapped paper and the rest is silted

|

|

|

Driving Unit

|

|

|

|

Method

|

Motor drive the axis

|

|

|

Pressing Wheel

|

Rubber

|

|

|

Bottom Driving Roll

|

Driven by principal axis

|

|

|

Driving Motor

|

Servo motor

|

|

|

Clamp

|

Driven by motor

|

|

|

Conveying of Wrapping Paper

|

|

|

|

Feeding Method

|

Photoelectric Control

|

|

|

Belt Drving

|

Belt and driving shaft

|

|

|

Belt Quantity

|

37 articles

|

|

|

Convey Method

|

pneumatic

|

|

|

Belt Clearing (Adjustable)

|

Adjustable and cleaning

|

|

|

Vacuum Source

|

0.4 Mpa

|

|

|

Ream Conveying

|

|

|

|

Conveying Method

|

Driving belt and driving axis

|

|

|

Ream Position Inspection (Input)

|

Photoelectric control

|

|

|

Ream Position Control (Input)

|

Photoelectric control

|

|

|

Ream Longitudinal Positioning

|

Photoelectric Positioning

|

|

|

Ream Transverse Positioning

|

Positioning Plate

|

|

|

Input Clamping Belt (Adjustable)

|

Robot

|

|

|

Front Board

|

Adjustable

|

|

|

Side Pushing Plate

|

Adjustable

|

|

|

Ream Wrapping Unit

|

|

|

|

Ream Lifting

|

Lifted by motor

controlled by photoelectric sensor

|

|

|

Upper Pressing of Ream

|

Vacuum Wrapping Paper

|

|

|

Front Pres of Ream

|

Adjustable positioning plate

|

|

|

Sealing of Ream Bottom

|

Sealing by hot-melt adhesive

|

|

|

Ream Side Folding

|

Fixed side folding plate

|

|

|

Side Sealing

|

Sealing by hot-melt adhesive

|

|

|

Side Guiding Plate (Adjustable)

|

Adjust the side guiding plate

|

|

|

Conveying Method

|

Belt Conveying

|

|

|

Side Conveying Belt

|

Adjustable side conveying belt

|

|

|

Driving Method of Conveying

|

Servo motor driving

|

|

|

Glue Spraying Unit

|

|

|

|

Gluing Method

|

Glue stripes

|

|

|

Glue Gun Qantity

|

3 pcs

|

|

|

Glue Hot-melter

|

kola

|

|

|

Glue Control

|

Photoelectric sensor

|

|

|

Ream Conveying Unit

|

|

|

|

Conveying Method

|

Belt

|

|

|

Driving of Conveying

|

Servo motor

|

|

|

Conveying Route

|

Put the ream into wrapping unit by hand

|

|

|

Anchor bolt , Nut and Washers

|

20 mm , 16 mm

|

|

Q1.Are you a manufacturer or a trading company?

A:Our shanghai office is mainly doing export.

We have our own factory in Wenzhou,Zhejiang Province.

Q2.What is the machine warranty?

A:One year.After the warranty,we still provide technical support to buyer at low cost.

Q3.What is the production time while placing order?

A:Normally about 10-20 days.

Q4.What is the delivery time?

A:15-30days after deposit.

Q5.Can your company handle shipping for customers?

A:Yes,just give us destination sea port or container yard.

Q6.Does the packing strong?

A:Yes.Adopts moisture-proof and shock-proof packaging which is suitable for long-distance road transportation and various types of weather conditions.

A full set of maintenance and operation manuals is included.

Q7.How about the machine installation and training?

A:1)We provide training in our factory for free;

2)We can send technicians (engineers) to your factory for installation and training.

You shall pay the round trip air fare and accommodations,plus each technician charges USD100/per day.

Q8.Do you have machines in stock?

A:For standard model,we have a large quantity in stock.

For special model,we need 20-30 days to produce it for you.

Q9.How can you assure the machines’ quality?

A:Each machine will be test running at least 24 hours before delivery to assure the quality.

And during the warranty,we will give

spare parts for free if machine has any problem.

Q10.Do you inspect machines or test running before packing?

A:Of course we do.We have QC department to debug the machine before packing.

If you want to use specific material to do the test running,you need to pay for the cost of the material.

Q11.What’s the payment term?

A:T/T 30% in advance,the balance shall be paid before delivery.

We also accept payment by West Union or L/C at sight.

Q12.Do you accept factory visiting?

A:Warmly welcome for your visiting.

Q13.How many years are you in printing field?

A:

The Shanghai company since in 2008,the factory is more than 25years.

Q14.How many clients do you have?

A:We have sold our machines to about 60 countries.

We have agents in South Africa,Morocco and Italy.

Hot Searches