- Product Details

- {{item.text}}

Quick Details

-

Elongation (≥ %):

-

35%

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

Industry

-

Grade:

-

Nickel

-

Model Number:

-

Inconel Pipe

-

Brand Name:

-

OEM ODM DZX DLX

-

Brand:

-

Inconel X750 625 718 600 601

-

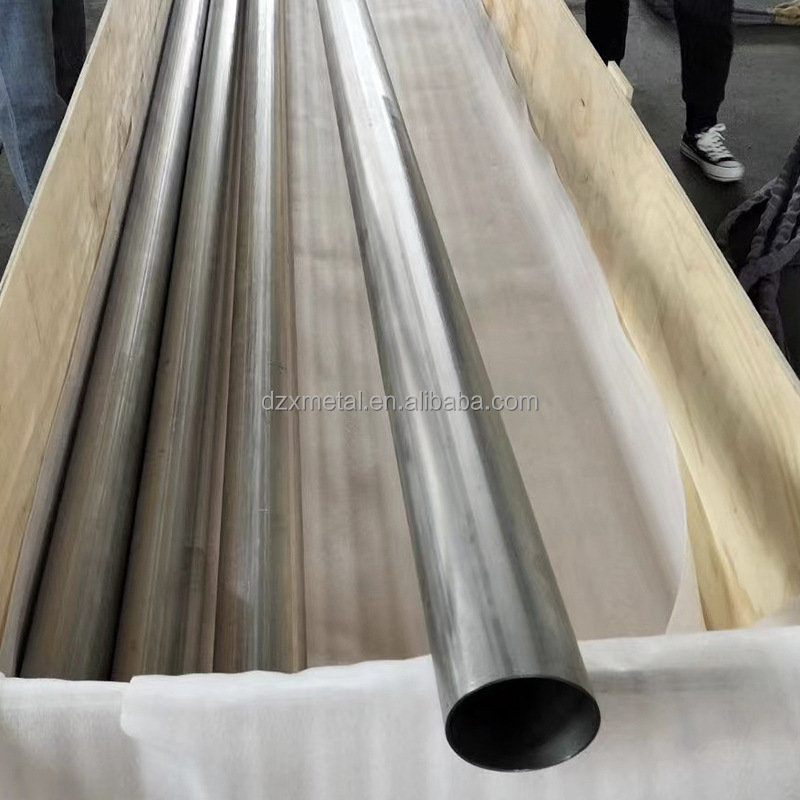

Technique:

-

Cold Rolled Hot Rolled Polishing

-

MOQ:

-

100KGS

-

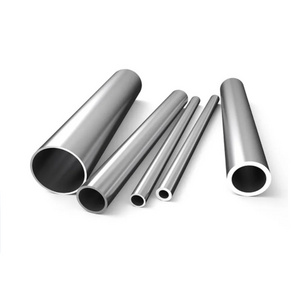

Shape:

-

Round Shape Bar Pipe Wire Foil

-

Surface:

-

Bright

-

Size:

-

Customized Size

-

Density:

-

8.2g/cm3

-

PRICE TERM:

-

CIF CFR FOB EX-WORK

-

Packing:

-

Carton Wooden

-

Material:

-

Nickel Alloy

Quick Details

-

Resistance (μΩ.m):

-

NA

-

Powder Or Not:

-

Not Powder

-

Ultimate Strength (≥ MPa):

-

462

-

Elongation (≥ %):

-

35%

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

Industry

-

Grade:

-

Nickel

-

Model Number:

-

Inconel Pipe

-

Brand Name:

-

OEM ODM DZX DLX

-

Brand:

-

Inconel X750 625 718 600 601

-

Technique:

-

Cold Rolled Hot Rolled Polishing

-

MOQ:

-

100KGS

-

Shape:

-

Round Shape Bar Pipe Wire Foil

-

Surface:

-

Bright

-

Size:

-

Customized Size

-

Density:

-

8.2g/cm3

-

PRICE TERM:

-

CIF CFR FOB EX-WORK

-

Packing:

-

Carton Wooden

-

Material:

-

Nickel Alloy

Inconel is a nickel-chromium-molybdenum alloy designed to resist a wide range of severely corrosive environments, pitting and crevice corrosion. This nickel steel alloy also displays exceptionally high yield, tensile, and creep-rupture properties at high temperatures. This nickel alloy is used from cryogenic temperatures up to long term service at 1200° F. One of the distinguishing features of Inconel 718’s composition is the addition of niobium to permit age hardening which allows annealing and welding without spontaneous hardening during heating and cooling. The addition of niobium acts with the molybdenum to stiffen the alloy’s matrix and provide high strength without a strengthening heat treatment. Other popular nickel-chromium alloys are age hardened through the addition of aluminum and titanium. This nickel steel alloy is readily fabricated and may be welded in either the annealed or precipitation (age) hardened condition. This superalloy is used in a variety of industries such as aerospace, chemical processing, marine engineering, pollution-control equipment, and nuclear reactors.

Application field:

High temperature components, such as turbine blades, guide vanes, turbine disks, high pressure compressor disks,machine manufacturing and combustion chambers used in the manufacture of aviation, naval and industrial gas turbines.

|

Item

|

Inconel600

|

Inconel 601

|

Inconel617

|

Inconel625

|

Inconel690

|

Inconel718

|

Inconel X750

|

Inconel825

|

|

C

|

≤0.15

|

≤0.1

|

0.05-0.15

|

≤0.08

|

≤0.05

|

≤0.08

|

≤0.08

|

≤0.05

|

|

Mn

|

≤1

|

≤1.5

|

≤0.5

|

≤0.35

|

≤0.5

|

≤0.35

|

≤1

|

≤1

|

|

Fe

|

6-10

|

rest

|

≤3

|

rest

|

7-11

|

rest

|

5-9

|

≥22

|

|

P

|

≤0.015

|

≤0.02

|

≤0.015

|

--

|

--

|

--

|

--

|

--

|

|

S

|

≤0.015

|

≤0.015

|

≤0.015

|

≤0.015

|

≤0.015

|

≤0.01

|

≤0.01

|

≤0.03

|

|

Si

|

≤0.5

|

≤0.5

|

≤0.5

|

≤0.35

|

≤0.5

|

≤0.35

|

≤0.5

|

≤0.5

|

|

Cu

|

≤0.5

|

≤1

|

--

|

≤0.3

|

≤0.5

|

≤0.3

|

≤0.5

|

1.5-3

|

|

Ni

|

≥7.2

|

58-63

|

≥44.5

|

50-55

|

≥58

|

50-55

|

≥70

|

38-46

|

|

Co

|

--

|

--

|

10-15

|

≤10

|

--

|

≤1

|

≤1

|

--

|

|

Al

|

--

|

1-1.7

|

0.8-1.5

|

≤0.8

|

--

|

0.2-0.8

|

0.4-1

|

≤0.2

|

|

Ti

|

--

|

--

|

≤0.6

|

≤1.15

|

--

|

--

|

2.25-2.75

|

0.6-1.2

|

|

Cr

|

14-17

|

21-25

|

20-24

|

17-21

|

27-31

|

17-21

|

14-17

|

19.5-23.5

|

|

Nb+Ta

|

--

|

--

|

--

|

4.75-5.5

|

--

|

4.75-5.5

|

0.7-1.2

|

--

|

|

Mo

|

--

|

--

|

8-10

|

2.8-3.3

|

--

|

2.8-3.3

|

--

|

2.5-3.5

|

|

B

|

--

|

--

|

≤0.006

|

--

|

--

|

--

|

--

|

--

|

|

Density

|

8.40 g/cm3

|

|

Ultimate Strength (≥ MPa)

|

700

|

|

Tensile Strength σb/MPa

|

760

|

|

Elongation δ5 (%)

|

30

|

|

Yield Strength σp0.2/MPa

|

345

|

|

Melting point

|

1290-1350°C

|

WELCOME TO VISIT US

CHANGZHOU DLX ALLOY CO, LTD

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing.

We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

Q. What is your working time?

A. Monday- Saturday : 7: 30AM-17: 00PM (Beijing time, GMT+08. 00)

We have public holiday during May.1-3, Oct. 1-7 and Chinese New Year holiday.

Pls email us during our holiday if u have any question.

Q. Do you provide free samples?

A. Yes, we can provide a free sample for testing, buyer should bear all the shipping costs.

Q. What is your payment terms?

A. T/T, L/C, D/A, D/P, Western Union, MoneyGram, Paypal

Q. What is the lead time?

A. Usually sample lead time is 7 days after payment has been confirmed.

Q. What's your contact information?

A. Mobile/ whatsapp/ skype/ wechat: +13270911653

Hot Searches