- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

GMK

-

Voltage:

-

380v/440v etc.

-

Power:

-

80KW

-

Dimension(L*W*H):

-

Customized Size

-

Applicable Industries:

-

battery

-

Weight (KG):

-

8000

-

Certification:

-

ISO9001

Quick Details

-

Machine Type:

-

Coating machine

-

Marketing Type:

-

New Product 2021

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GMK

-

Voltage:

-

380v/440v etc.

-

Power:

-

80KW

-

Dimension(L*W*H):

-

Customized Size

-

Applicable Industries:

-

battery

-

Weight (KG):

-

8000

-

Certification:

-

ISO9001

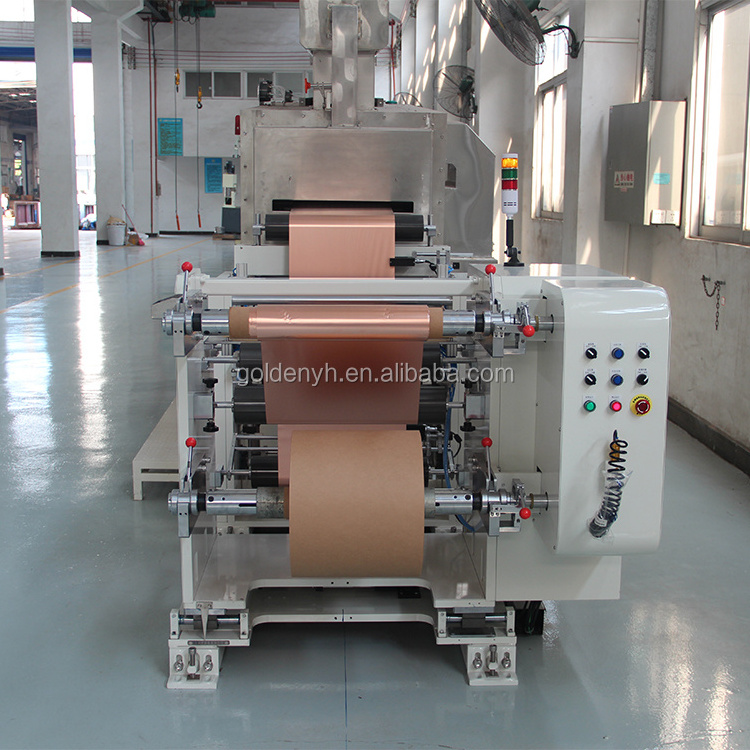

GMK Li-thium Slurry Anode Coating Slot Die Double Surface Coater

Feature and advantage:

1.Enabling continuous coating, gap coating, stripe coating, the rectangle shaped coating;

2.Coater can speed up to 25m/min;

3.The dry thickness accuracy of the coater can be controlled within ±1.0µm/single surface;

4.Oven using floating structure, evenly air flow, high drying efficiency;

5.Heating modes including electric heating, steam heating, oil heating, gas heating etc.

Temperature control precision can reach ± 1 ºC , each section of the cabinet have ex-proof setting. It is safe and reliable, energy saving and environmental protection

6.The machine can be equipped with online areal density or thickness tester, real-time monitoring the changes of areal density or thickness during coating process.

The feeding system can be closed-loop adjusted automatically through PLC controlsystem to ensure consistency of the coating layer. All data can be recorded;

7.The coater length plus the length of the blank can be controlled within the precision ± 1mm,positive and negative face counterpoint error ± 0.5mm.Provided with a rewind function,fault alarm and fault display function ,operation interlock,emergency stop functionand the communication function.

Technical parameter:

|

Type

Item |

LJT600-24/36 |

LJT750-24/36 |

LJT750-24/36-S |

| Coating width | Max:500mm | Max:650mm |

Max:650mm |

| Maximum coating speed | 25m/min | 25m/min | 25m/min |

| Machine speed | 0~30m/min | 0~30m/min | 0~30m/min |

| Single thickness accuracy | ±1.0µm | ±1.0µm |

±1.0µm |

|

The areal density the error |

≤ ±1.0% | ≤ ±1.0% | ≤ ±1.0% |

| Minimum gap |

8mm

Related to the characteristics of the coating speed and slurry |

8mm

Related to the characteristics of the coating speed and slurry |

8mm Related tot he characteristics of the coating speed and slurry |

|

Positive and negative coated overlay error |

±0.5mm | ±0.5mm |

±0.5mm |

|

6mm thickness error within the coater head and tail |

±5.0µm | ±5.0µm |

±5.0µm |

| Length error | ±0.5mm | ±0.5mm | ±0.5mm |

| Orderly winding error | ±0.5mm | ±0.5mm | ±0.5mm |

| Retractable roll diameter |

Max:φ550mm |

Max:φ550mm |

Max:φ550mm |

| Extrusion head die lip straightness | 2µm/m | 2µm/m | 2µm/m |

| Back steel roller | φ200mm Circular Run ≤ 1.5µm | φ200mm Circular Run ≤ 1.5µm | φ200mm Circular Run ≤ 1.5µm |

| Air pressure | 0.5~0.8MPa | 0.5~0.8MPa | 0.5~0.8MPa |

| Power | 190Kw/230Kw | 190Kw/230Kw | 360Kw/490Kw |

| Machine Dimensions(LxWxH) |

31mx3.0mx2.8m(drying box 24m)

43mx3.0mx2.8m(drying box 36m) |

31mx3.5mx2.8m(drying box 24m) 43mx3.5mx2.8m(drying box 36m) |

35mx3.5mx3.6m(drying box 24m) 47mx3.5mx3.6m(drying box 36m) |

GMK can be customized according to customer demand for non-standard equipment

If you are not certain of which type to choose, please contact us and our professional sales engineers will recommend for you.

Technology innovation service:

We keep on technology innovation to meet the customers' demand and can provide technology improvement program.

If you are planning to research and manufacture Li-ion battery, contact us, we provide one stop solution for you.