- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

POLYSUN

-

Voltage:

-

220V/380V/customizable

-

Dimension(L*W*H):

-

10*2*1.5M

-

Power (kW):

-

110

-

Weight:

-

3000 KG

-

Type:

-

Plastic Extrusion

-

After-sales Service Provided:

-

Engineers

-

Usage:

-

Plastic Extrusion

-

Motor:

-

SIEMENS Brand

-

Function:

-

profile/board

-

Color:

-

Customer Choice

-

Capacity:

-

350-500kg/hr

-

Keywords:

-

Extruder Machine Plastic Recycling

-

Cooling way:

-

Water Cooling+Air Cooling

-

Processing Type:

-

Extrusion Machine

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

38:1

-

Screw Speed (rpm):

-

36 rpm

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

POLYSUN

-

Voltage:

-

220V/380V/customizable

-

Dimension(L*W*H):

-

10*2*1.5M

-

Power (kW):

-

110

-

Weight:

-

3000 KG

-

Type:

-

Plastic Extrusion

-

After-sales Service Provided:

-

Engineers

-

Usage:

-

Plastic Extrusion

-

Motor:

-

SIEMENS Brand

-

Function:

-

profile/board

-

Color:

-

Customer Choice

-

Capacity:

-

350-500kg/hr

-

Keywords:

-

Extruder Machine Plastic Recycling

-

Cooling way:

-

Water Cooling+Air Cooling

-

Processing Type:

-

Extrusion Machine

PRODUCT OVERVIEW

900-1220mm with PVC and WPC solid foamed furniture board and solid door board making machine with CE certificate

WPC solid board making machine for 30-45mm thickness e is used for making 30-45mm solid WPC foam board for door panel, it uses PVC and wood fiber as raw material, by semi-crust or full-crust foaming technology, to make WPC solid boards/panels with low density for 0.45-0.8gram/cm3, the WPC foam boards are widely used for making furniture panel, construction formwork, partition wall....

WPC solid board making machine for 30-45mm thickness e is used for making 30-45mm solid WPC foam board for door panel, it uses PVC and wood fiber as raw material, by semi-crust or full-crust foaming technology, to make WPC solid boards/panels with low density for 0.45-0.8gram/cm3, the WPC foam boards are widely used for making furniture panel, construction formwork, partition wall....

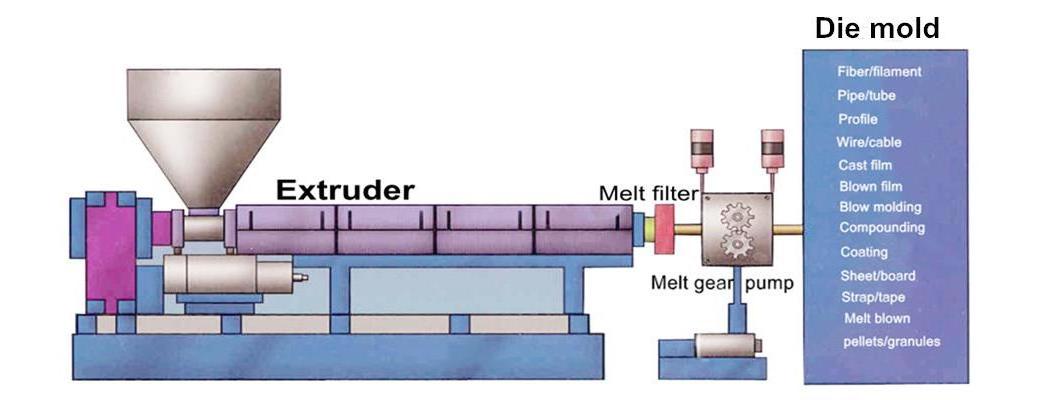

PVC/WPC board machine can continuously produce PVC WPC foam board.This production line is composed of extruder, mould, calibrating platform, cooling frame, haul off machine, cutting machine and stacker.

The customer can also produce A+B+A three layers co-extrusion foam board by adding extruder and distributor .The machine should equip with water chiller, can increase production efficiency.

The customer can also produce A+B+A three layers co-extrusion foam board by adding extruder and distributor .The machine should equip with water chiller, can increase production efficiency.

PRODUCT PARAMETERS

SUCCESSFUL PROJECT

ALL ABOUT PLASTEX

PLASTEX INTERNATIONAL TRADING CO.,LTD/POLYSUN EXTRUSION EQUIPMENT CO.,LTD

FAQ

Q: Are you a trading company or factory?

A: We are a factory with a foreign trading department. We manufacture the plastic extruder machine by our own factory. So don't worry about the after-sell services.

Q: Where is your factory? How do I get there?

A: Factory address: Xingda Industrial Park, No. 720, North Section of Tongdu Avenue, Tongling City, Anhui Province, China. You can take a plane to Hefei Xinqiao International Airport or Nanjing Lukou International Airport, we can arrange the pick-up. Or you can take the high-speed rail to Tongling Station.

Q: In what year was your company founded?

A: Our company was founded in 2012, the founder Mr. Yuan Xu has been engaged in the plastic machinery and mold processing industry for more than 20 years.

Q: What payment methods do you support?

A: We support T/T, Western Union, PayPal, and other payment methods.

Q: What shipping methods do you support?

A: Sea transportation, air transportation, railway transportation, and road transportation, etc. Usually, we go by sea.

Q: What is your packaging?

A: Our conventional packaging is: Wrap the plastic film around the machine, and then put the machine in a wooden box.

Q: What is your delivery time?

A: Generally speaking, the delivery time of a production line is about 50 days.

Q: How is your after-sales service?

A: Our equipment has an 18-month warranty and supports lifetime maintenance. We have a strong technical service team.

Hot Searches