- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zhengxia

-

Dimension(L*W*H):

-

3600x2250x3800

-

Weight:

-

2000 KG

-

Product name:

-

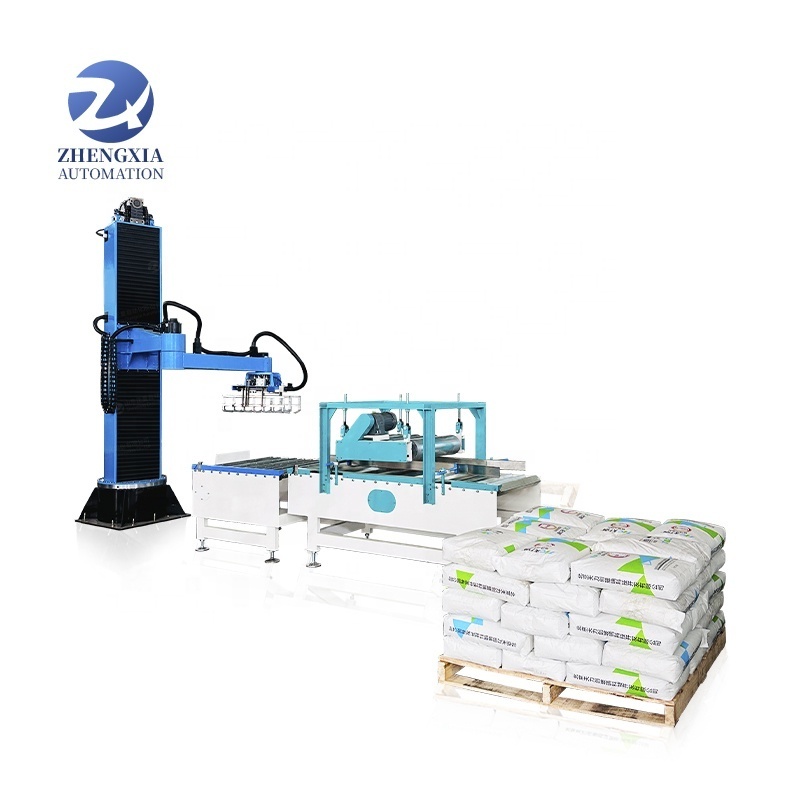

Single Column Robot Palletizer Machine Automatic

-

Keywords:

-

Column Palletizer Automatic Pack Box Case Bag

-

Function:

-

Automatic Packaging Line, Palletizering line

-

Material:

-

Carbon steel

-

Speed:

-

300-400pcs/hour

-

After-sales Service Provided:

-

Provided

-

Certification:

-

CE

-

Applicable Product:

-

Box, Case, Rice Bags, 25kg 50kg Cement Bags

Quick Details

-

Application:

-

Food, Beverage

-

Packaging Material:

-

Plastic, Paper, Wood

-

Voltage:

-

220V/380V 50Hz Or Customized

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zhengxia

-

Dimension(L*W*H):

-

3600x2250x3800

-

Weight:

-

2000 KG

-

Product name:

-

Single Column Robot Palletizer Machine Automatic

-

Keywords:

-

Column Palletizer Automatic Pack Box Case Bag

-

Function:

-

Automatic Packaging Line, Palletizering line

-

Material:

-

Carbon steel

-

Speed:

-

300-400pcs/hour

-

After-sales Service Provided:

-

Provided

-

Certification:

-

CE

-

Applicable Product:

-

Box, Case, Rice Bags, 25kg 50kg Cement Bags

Shandong Zhengxia Automation Co.,Ltd is one of the China’s leading manufacturers and suppliers of industrial bag packaging machines. With one of the largest product portfolios in the industry, Shandong Zhengxia can provide packing machines for almost any kind of bags heavier than 5 kg. Our company offers a comprehensive product portfolio, including manual packing machines, big bag fillers, open-mouth bagging machines, packing lines, column palletizer and robot palletizer etc. For more information about these bagger machines, see the page below.

MACHINE SHOW

|

Brand

|

ZHENGXIA

|

|

Palletizer speed

|

250-350 bags/h

|

|

Workable bag weights

|

from 1 to 50 kg

|

|

Stacking Type

|

5/6/7/8/9/10 bags per layer or customized

|

|

Voltage

|

380 V 50 HZ or Customized

|

|

Working Temperature

|

-20~50℃

|

|

Operating system

|

PLC

|

|

Application

|

bags, cases, boxes, bottles, barrels

|

1.Free CAD drawing design

2.Provide teaching services

3.Provide on-site installation services

4.Provide one year warranty

5.Machine LOGO and color can be customized

PRODUCT DETAILS

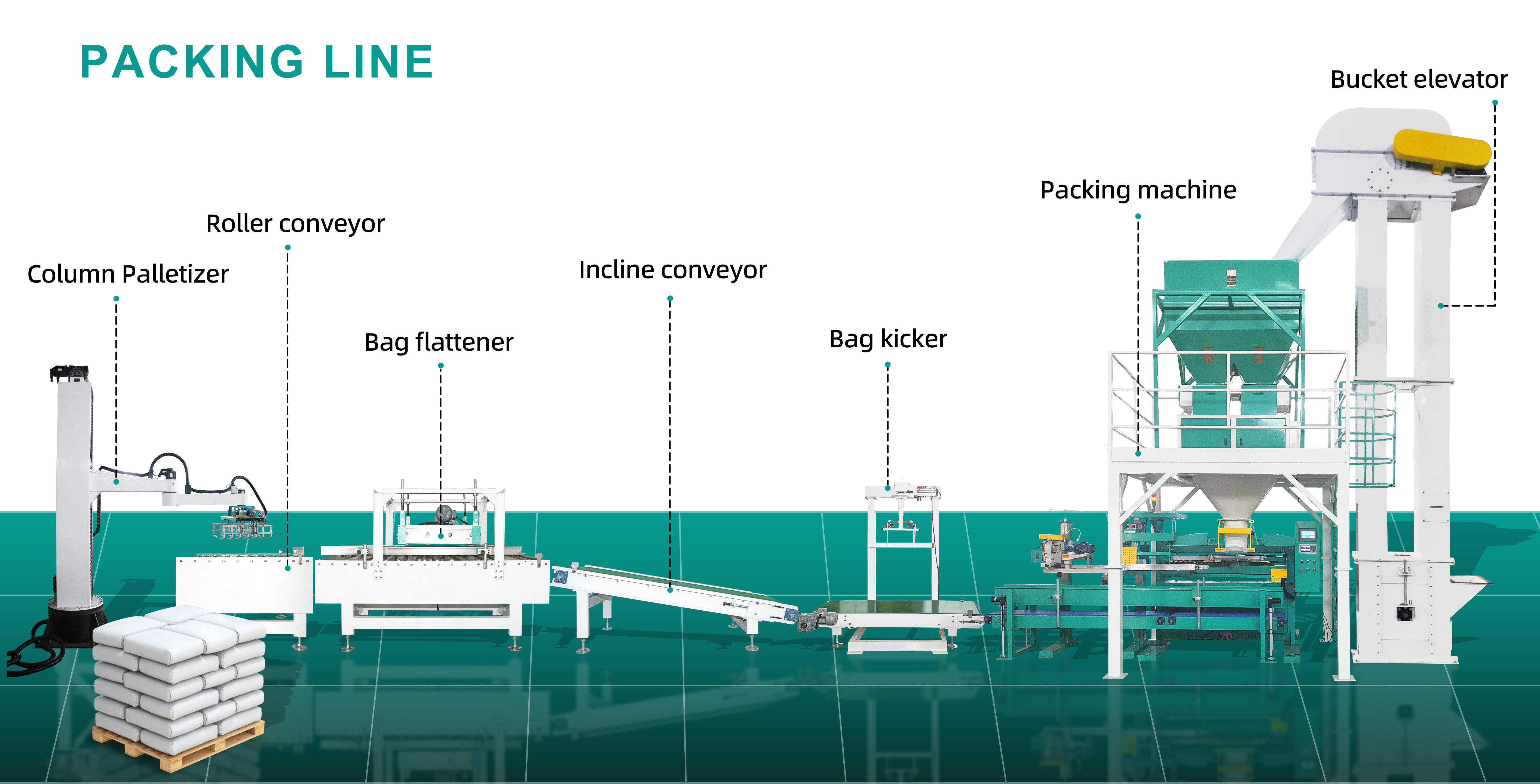

Column palletizer

•

Fast palletizing speed and stable palletizing can greatly save labor costs.

• Small size saves space and is convenient for transportation

• Can be used for palletizing bags, cases, boxes, bottles and barrels

• Small size saves space and is convenient for transportation

• Can be used for palletizing bags, cases, boxes, bottles and barrels

•

The palletizing process is fully automated without manual intervention

Gripper

Pneumatic drive, sturdy, lightweight, and flexible

Customizable grippers for grabbing bags, cases, bottles, barrels

Customizable grippers for grabbing bags, cases, bottles, barrels

Bag Kicker

Standing bags are transported to this position, and through the detection of photoelectric switches, it is judged whether the bag has reached the position of pushing the bag. After arriving, the cylinder works and kicks the bag down to a horizontal state and transports it to the Incline Conveyor.

Incline Conveyor

The Incline conveyor is mainly used for the transportation of the product. Inclined conveying makes the material inside the bag flat, ready for the next step of shaping and at the same time play the role of cache packing bags .

Bag Flattener

The bag is shaped and flattened by the square roller vibrating conveyor , so that the stacking shape is neat and secure,The shaping conveyor can open a certain distance between the products, which is convenient for photoelectric detection and subsequent palletizing.

Roller Conveyor

The bag is conveyed to the Roller Conveyor, the sensors on both sides will detect the bag, stop the conveying and link the palletizer to grab the bag.

MACHINE COMPONENTS

PROJECT SHOW

PRODUCT RECOMMEND

COMPANY PROFILE

PACKAGING & DELIVERY

FAQ

Q1: Are you factory or trading company?

A1: We are the factory, we doing this line for more than 10 years.

Q 2: How to choose suitable packaging machine?

A2: Need to provide your material pictures and requirements, such as packaging speed, packaging weight, bag type and bag size.

Q3: How to ensure the quality of the machine?

A3: We usually delivery the machine after successful inspection in our factory. We have our own quality control department,beforethe delivery we have to running the machine for three days without problem. You can send us your materials and we will make video as long as you want. Or you can arrange a third-party inspection agency.

Q4: How to install the equipment?

A4: We will provide manuals and detailed videos to help customer install machine. If necessary, we will send technicians to the customer's factory to assist, and the customer only needs to pay for round-trip air tickets, meals, room expenses and a daily subsidy of 150 US dollars.

Q5: What's your payment way?

A5: T/T by our bank account directly, or by Alibaba trade assurance service, or by West Union, or L/C.

A1: We are the factory, we doing this line for more than 10 years.

Q 2: How to choose suitable packaging machine?

A2: Need to provide your material pictures and requirements, such as packaging speed, packaging weight, bag type and bag size.

Q3: How to ensure the quality of the machine?

A3: We usually delivery the machine after successful inspection in our factory. We have our own quality control department,beforethe delivery we have to running the machine for three days without problem. You can send us your materials and we will make video as long as you want. Or you can arrange a third-party inspection agency.

Q4: How to install the equipment?

A4: We will provide manuals and detailed videos to help customer install machine. If necessary, we will send technicians to the customer's factory to assist, and the customer only needs to pay for round-trip air tickets, meals, room expenses and a daily subsidy of 150 US dollars.

Q5: What's your payment way?

A5: T/T by our bank account directly, or by Alibaba trade assurance service, or by West Union, or L/C.

Hot Searches