- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

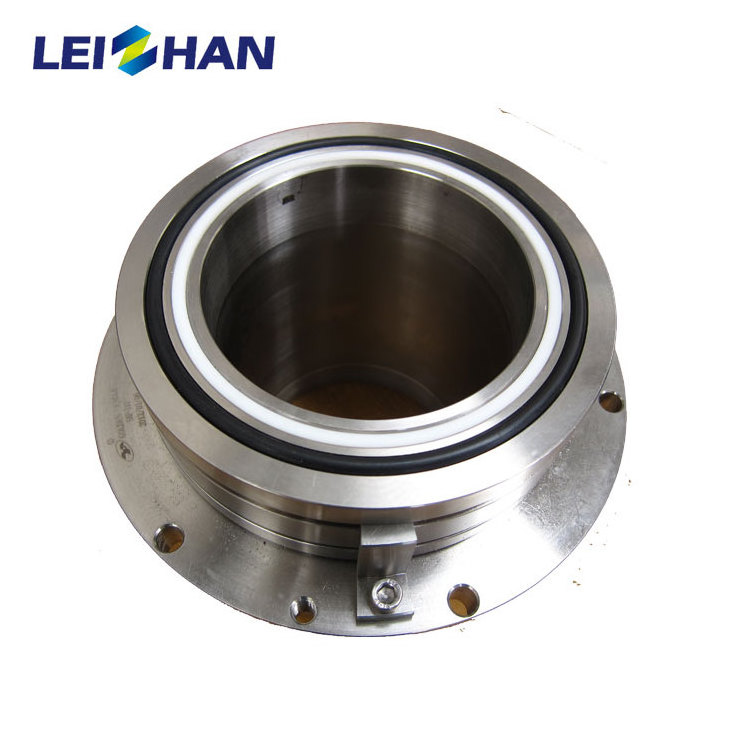

ZNS mechanical seal

-

Product name:

-

Pressure screen mechanical seal

-

Standard or Nonstandard:

-

Standard

-

Feature:

-

Wear resistant

-

Experience:

-

40 years

-

What we can provide:

-

pulp and paper making production line

-

Dimension(L*W*H):

-

Up to each model

-

Type:

-

Pulping Equipment parts

-

Weight:

-

Up to each model

-

Keyword:

-

50mm single cartridge mechanical seal

-

Usage:

-

paper mill, waste paper pulp factory

Quick Details

-

Size:

-

/

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Leizhan

-

Model Number:

-

ZNS mechanical seal

-

Product name:

-

Pressure screen mechanical seal

-

Standard or Nonstandard:

-

Standard

-

Feature:

-

Wear resistant

-

Experience:

-

40 years

-

What we can provide:

-

pulp and paper making production line

-

Dimension(L*W*H):

-

Up to each model

-

Type:

-

Pulping Equipment parts

-

Weight:

-

Up to each model

-

Keyword:

-

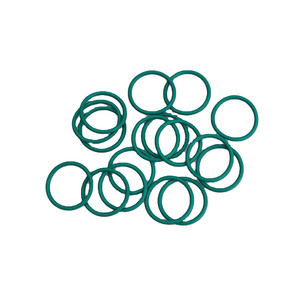

50mm single cartridge mechanical seal

-

Usage:

-

paper mill, waste paper pulp factory

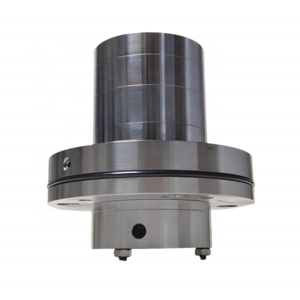

Pressure Screen Mechanical Seal For Paper Mill

Mechanical seal introduction

1. Usage:

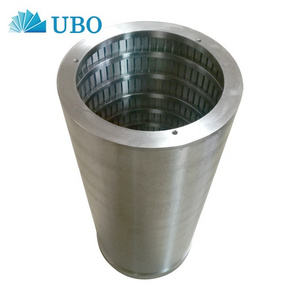

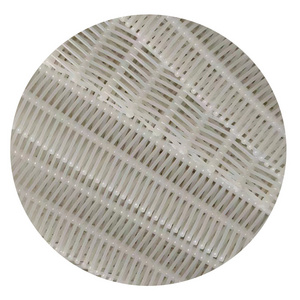

This mechanical seal mainly uesd for paper mill presssure screen, to screen waste paper pulp and washed pulp, wood pulp,and also can be used as thermal screening equipment for after cooking before washing pulp.

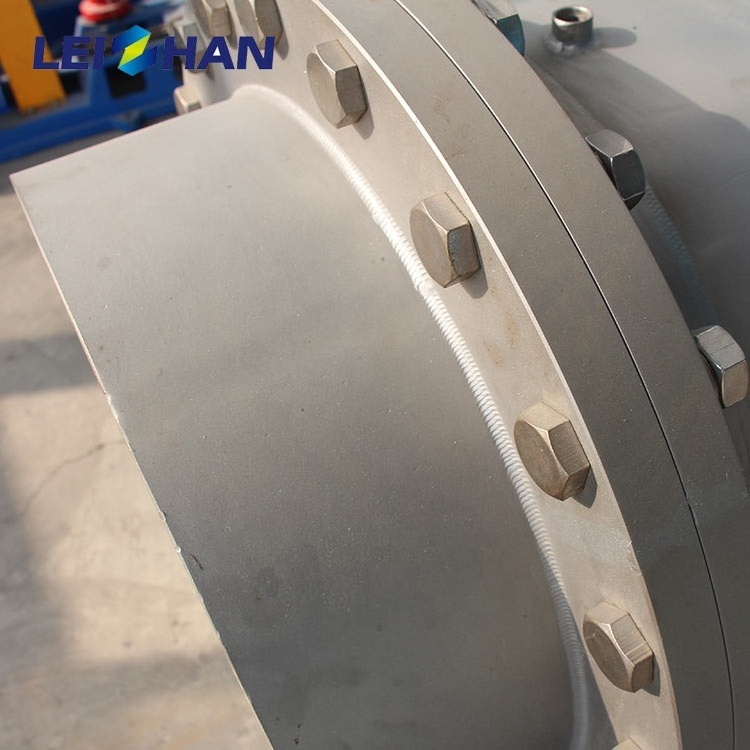

Following is double mechanical seal

2. Features :

With many rotor blades, no winding, highly effeicient rotary rotor, high-frequency pilse, specially used for coarse and fine screening of various recycled pulp.

3. Application :

Delivery Site :

1.Pre-sales Service

- Offering comprehensive technical and business consultation services;

- Proposing the most suitable scheme and equipment for our clients;

- Designing and fabricating targeted products according to the special requirements of clients;

- Training periodically high qualified service technician.

2.After-sales Service

- Highly inspecting equipments in every working procedure, quality comes first;

- Fast & Safe Delivery;

- Assisting our clients for foundation construction of equipments;

- Dispatching engineers to install and debug equipments;

- Training the first-line operators on site;

- Regularly visit clients to solve production problems;

- Providing life-long maintenance service;

- Providing technical exchanging;