4. Optional pressure reducing device for online high pressure measurement;

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

LPC

-

Model Number:

-

LPC-M

-

Function:

-

for the degree of particle contamination and moisture in the oil

-

Light source:

-

semiconductor laser

-

Flow rate range:

-

20-500mL/min

-

Viscosity of the sample to be tested:

-

≤350cSt

-

Online detection pressure:

-

0.1-3Mpa

-

Particle size range:

-

1-500μm

-

Data storage:

-

Provide 1000 sets of data storage space and support USB storage

-

Counting volume:

-

1-999ml

-

Protection level:

-

IP56

-

Test interval:

-

1 second - 24 hours

Quick Details

-

Warranty:

-

1 year

-

Power:

-

Electronic

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

LPC

-

Model Number:

-

LPC-M

-

Function:

-

for the degree of particle contamination and moisture in the oil

-

Light source:

-

semiconductor laser

-

Flow rate range:

-

20-500mL/min

-

Viscosity of the sample to be tested:

-

≤350cSt

-

Online detection pressure:

-

0.1-3Mpa

-

Particle size range:

-

1-500μm

-

Data storage:

-

Provide 1000 sets of data storage space and support USB storage

-

Counting volume:

-

1-999ml

-

Protection level:

-

IP56

-

Test interval:

-

1 second - 24 hours

Product Description

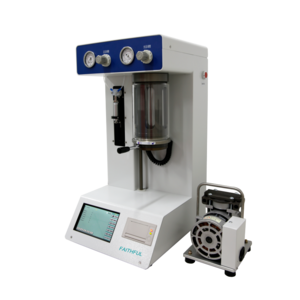

LPC-M Online Lube Engine Oil Particle Device/Oil Quality Analyzer

(Detecting the degree of particle contamination and moisture in the oils)

The LPC-M Online Oil Particle and Moisture Analyzer is photoresist (light shading) counting principle specified by the International Hydraulic Standards Committee.The Online Oil Particle and Moisture Analyzer is mainly capable of detecting the degree of particle contamination and moisture in the oil. It has the advantages of small volume, light weight, fast detection speed, high precision and good repeatability, and can work under high temperature and high pressure environment. It is applicable for the measurement of engine oil, gear oil, transformer oil (i.e. insulating oil), hydraulic oil, lubricating oil, synthetic oil and other oils, widely used in aerospace, petrochemical, transportation ports, steel metallurgy, automobile manufacturing and other fields.

Specification

|

1. Light source: semiconductor laser

2. Flow rate range: 20-500mL/min 3. Viscosity of the sample to be tested: ≤350cSt 4. Online detection pressure: 0.1-3Mpa (optional decompression device maximum pressure up to 40Mpa) 5. Particle size range: 1-500μm (select different types of sensors) 6. Interface: USB interface, RS232 interface, RS485 interface 7. Data storage: Provide 1000 sets of data storage space and support USB storage 8. Sensitivity: 1μm or 4μm (c) 9. Limit coincidence error: 10,000 grains/ml 10. Counting volume: 1-999ml 11. Counting accuracy:±0.5 pollution degree levels 12. Protection level: IP56 13. Test interval: 1 second - 24 hours 14.Temperature collection T: Collection range: 1-100℃; Measurement accuracy: 1℃; Response time: 30s 15. Water activity collection aw Collection range: 1-100% RH; Measurement accuracy: 1% RH; Response time: 30s 16. Absolute water content AH: Collection range: 1-120ppm; Measurement accuracy: 1ppm; Response time: 30s 17. Test sample temperature: 0-80℃ 19. Working temperature: -20-60℃ 19. Power supply: AC 220V±10%, 50/60Hz or DC12-40V 20. Weight: 1.1kg 21. Dimension: 115×85×60mm |

|

|

Features

1. Adopts the principle of photoresist (shading), high-precision laser sensor, small size, high precision, stable performance;

2. Suitable for on-site inspection, real-time monitoring of particle contamination in the oil system;

3. Built-in data analysis system, can display the real data of the particle size of each channel and automatically determine the sample level;

|

5. With volume flushing and duration flushing mode, convenient for usage and maintenance;

6. Built-in ISO4406, NAS1638, SAE4095,GJB420A, GJB420B, ГOCT17216, GB/T14039 and other particle pollution level standards;

7. Built-in calibration function, can be calibrated according to GB/T21540, ISO4402, GB/T18854 and other standards; 8. Any alarm level can be set to achieve pollution degree or cleanliness detection;

9. RS232 or RS485 interface, can be connected to computer or other equipment for data monitoring and processing;

10. Large storage, optional storage in the internal or external storage device;

11. Firm exterior structure for complex working environment; |

12.Sturdy structure, suitable for complex working environment

13.The upper and lower positions of the oil outlet are optional, which is convenient for installation.

14.Can test continuously or set test interval arbitrarily

15.Optional 4G module, support remote data monitoring, historical data, and curve query on mobile phones or computers

16.Optional built-in moisture and temperature sensor module

Packing & Delivery

About Us

Chongqing Blossom Machinery Equipment Co., Ltd is located in Chongqing, one of the municipalities directly under the central government. The main products include instrument and apparatus, mechanical machinery such as liquid purification equipment and electric hoist, etc. The equipment is widely applied in construction, petroleum, mechanical, ships, pharmaceutical, lab test and edible oil processing, etc.

Factory Manufacture

Testing Equipment in stock

Certificates

Why Choose Us

FAQ

1. What's the payment method?

Payment can be done by cash T/T, L/C, Western Union, Alibaba Trade Assurance,etc.

2. How long is the delivery period?

Generally it takes about 30 working days for production and then the delivery will be done timely.

3.What's the package made of?

The package is made of international export standard wooden case.

4.What's the delivery method?

By train, by air, by sea, by truck, by express, etc.

5. How long is the guarantee period?

The guarantee period is 2 years due to the product quality problems itself.

6.What services can you provide?

Online support through email, telephone, Whatsapp or other communication method; onsite taining and installation if you need;

filed maintenance and repair, technical video support, etc.

Payment can be done by cash T/T, L/C, Western Union, Alibaba Trade Assurance,etc.

2. How long is the delivery period?

Generally it takes about 30 working days for production and then the delivery will be done timely.

3.What's the package made of?

The package is made of international export standard wooden case.

4.What's the delivery method?

By train, by air, by sea, by truck, by express, etc.

5. How long is the guarantee period?

The guarantee period is 2 years due to the product quality problems itself.

6.What services can you provide?

Online support through email, telephone, Whatsapp or other communication method; onsite taining and installation if you need;

filed maintenance and repair, technical video support, etc.

Hot Searches