- Product Details

- {{item.text}}

Quick Details

-

Bending Precision (Deg):

-

0.1

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Krrass

-

Year:

-

2023

-

Power (kW):

-

4

-

Weight (KG):

-

750

-

Marketing Type:

-

Hot Product 2023

-

Brand:

-

KRRASS or OEM

-

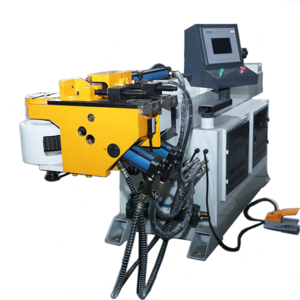

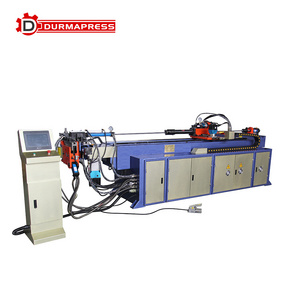

Model:

-

DW38,50,63,75,89,115,130,168NC

-

Automatic:

-

Semi-automatic

-

Feeding Method:

-

Direct feeding or Pinch feeding

-

Max. Feeding Length:

-

3000mm or customized

-

Max. Bending Angle:

-

190°

-

Bending Precision:

-

±0.1

-

Controller:

-

PLC+Touch screen

-

Valve group:

-

YUKEN-Japan

-

Servo motor & drive:

-

MITSUBISHI-Japan

Quick Details

-

Machine Type:

-

DW NC

-

Bending Radius (mm):

-

1 - 200

-

Max. Bending Angle (Deg):

-

190

-

Bending Precision (Deg):

-

0.1

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Krrass

-

Year:

-

2023

-

Power (kW):

-

4

-

Weight (KG):

-

750

-

Marketing Type:

-

Hot Product 2023

-

Brand:

-

KRRASS or OEM

-

Model:

-

DW38,50,63,75,89,115,130,168NC

-

Automatic:

-

Semi-automatic

-

Feeding Method:

-

Direct feeding or Pinch feeding

-

Max. Feeding Length:

-

3000mm or customized

-

Max. Bending Angle:

-

190°

-

Bending Precision:

-

±0.1

-

Controller:

-

PLC+Touch screen

-

Valve group:

-

YUKEN-Japan

-

Servo motor & drive:

-

MITSUBISHI-Japan

More machine videos ,pls check:

KRRASS Youtube account:

DW63NC large diameter pipe bender boiler pipe hot bending cnc pipe bending machine for sales

1. Structural style:

1. NC pipe bending machine adopts boom lifting clamp structure

2. Hydraulic bending mode

3. Hydraulic guide side pushing mechanism

4. Hydraulic system is equipped with water cooling device, which is convenient for users to control the oil temperature

5. Pipe bending direction is clockwise from top view

2. Electrical control and operation interface

1. The operation interface of NC hydraulic pipe bending machine adopts single chip microcomputer.

2. Digital display resolution: turn 0.15 °

3. NC hydraulic pipe bending machine adopts single chip microcomputer controller.

4. Bending parameters can be set (preset) on the operation interface.

3. Bend quality requirements:

1. No creasing is allowed on the pipe surface at the bend.

2. No trench and obvious depression is allowed on pipe surface after bending

4. NC hydraulic pipe bending machine with the following characteristics:

1. Maximum memory capacity can up to 16 bends per group.

2. Directly input bending machining parameters, the machine can be executed step by step and suspended during

automatic operation, so that the special pipe can be manually interfered when bending, and the automatic operation

can be resumed with automatic and manual pause, emergency stop function.

3. Working program and bending program memory storage time is unlimited, and will not be lost due to power outage

or long-term use.

4. Program edit with minor correction input, the original processing data will not be lost due to multi-times grogram

modification.

5. With processing quantity and processing time counting function

6. Real-time display the position and bending angle of each action axis on screen

7. In case of any accident or error during automatic processing, the machine can be suspended, and the machine can

continue to finish the unfinished work, so as to avoid the waste.

8. Automatic or manual mode setting can be set according to the difference of processing feature, such as whether

there is a piercing heart, auxiliary push and so on.

9. With multiple delay parameter settings, the most appropriate time difference can be set for each action axis to meet

the requirements of various bending changes.

10. The machine is with automatic detection function of each button and circuit output/input board, which can easily

find the possible fault location.

11. Closed-loop control

| No. | Name | Manufacturer Or Material |

| 1 | Machine Body | 45 Steel plate welded(Tempering Treatment) |

| 2 | Machine Head | ductile cast iron(QT500-7) |

| 3 | Pipe-bending Arm | precision casting ZG45 steel |

| 4 | Slider | 45 forged steel |

| 5 | (Low ,high speed) bearing | NSK-Japan |

| 6 | Sealing Ring | NOK-Japan |

| 7 | Main Motor | Taihu-Wuxi |

| 8 | Single Chip | OMRON electron-China |

| 9 | Valve Block | YUKEN-Japan |

| 10 | Encoder | NEMICON-Japan |

| 11 | NEMICON-Japan | NOVA- USA |

| 12 | AC Contactor | Schneider- France |

| 13 | Thermal Overload Relay | Schneider- France |

| 14 | Fuse | Schneider- France |

| No. | Parameter | Unit | NC38 | NC50 | NC63 | NC75 | NC89 | |

| 1 | Max. Pipe Diameter | mm | Φ38×2 | Φ50×3 | Φ63×4 | Φ75×4 | Φ89×5 | |

| 3 | Max. Bending Capacity for Square Pipe ( Outside Dia. *Wall Thickness) | mm | 30*30*2 | 40*50*2 | 50*50*2 | 60*60*2 | 70*70*2 | |

| 4 | Max. Bending Radius | mm | R200 | R350 | R350 | R400 | R450 | |

| 5 | Min. Bending Radius | mm | Depending on pipe diameter(2 times of pipe outer diameter) | |||||

| 6 | Max. Bending Angle | Degree | 190 | 190 | 190 | 190 | 190 | |

| 7 | Max. Core-Piercing Distance | mm | 1600 | 2200 | 2600 | 2800 | 3200 | |

| 8 | Main Oil Cylinder Diameter | mm | 75 | 95 | 110 | 140 | 160 | |

| 9 | Die Center height from ground | mm | 950 | 1000 | 1000 | 1100 | 1100 | |

| 10 | Cycling Speed Every 90 Degrees | s | 3 | 4 | 5 | 8 | 10 | |

| 11 | Controller | Single chip | ||||||

| 12 | Data Input Mode | Manually input | ||||||

| 13 | Max. Bending Number Per Pipe | PCS | 16 | |||||

| 14 | Working Speed | Bending Speed | mm/s | 65 | ||||

| Bending Precision | ±0. 1 | ±0. 1 | ||||||

| 15 | Main Motor Power | Kw | 4 | 5.5 | 7.5 | 7.5 | 11 | |

| 16 | Max. Pressure | MPa | 12 | 12 | 12 | 12 | 16 | |

| 17 | Hydraulic System Control | Solenoid valve | ||||||

| 18 | Oil Tank Volume | L | 150 | 220 | 220 | 250 | 450 | |

| 19 | Machine Weight | Kg | 750 | 1220 | 1500 | 2000 | 4000 | |

| 20 | Outline Dimension | mm | 2400×700×1220 | 3000×700×1030 | 3500×750×1100 | 400×100×110 | 4600×1200×1400 | |

|

|

|

|

Shearing Machine |

Laser Cutting Machine |

Ironworker Machine |

|

|

|

|

| Plate Rolling Machine |

V Groover Machine |

Q1: Why customer choose us?

A: Nanjing Krauss CNC Machinery Co., Ltd. (KRRASS) is a professional, serious and responsible sheet metal machinery manufacturer.

Our factory is one of the largest and best in the local area. Our machines are of good quality and are sold to 92 countries around the world. They are well received by customers.Many customers have become our regular customers.

Q2: Are you a manufacturer or trading company?

A: We are professional manufacturer with big modern factory in Maanshan,Anhui,China. Both OEM & ODM service can be accepted.

Q3: What's your delivery time?

A: Generally 25 to 35 days, if urgently order, pls contact our sales in advance.

Q4: How long is your machine warranty?

A: 2 years warranty for the main components, 10 years for the whole structure.

Q5: How long could your machine be used?

A: Generally, more than 10 years.

Q6: What's payment term?

A: T/T, L/C, Western Union, Paypal, Credit Card, and etc. Also we could accept USD, RMB, Euro and other currency.

Q7: How about your customer service?

A: 24 hours on-line service available. 48hours problem sovled promise.

Q8: How about your after-sales service?

A: 1. Provide customers with intallation and commissioning online instructions.

2. Well-trained engineers available to overseas service.

3. Worldwide agents and after service avaiable.