There are 3 types: pneumatic, hydraulic and manual.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

380V/50HZ

-

Power:

-

depends on specifications

-

Weight:

-

20000 kg

-

Raw material:

-

Low-carbon Steel

-

Pipe shape:

-

Round Square Rectangle Pipe

-

Color:

-

Customer's Requirement

-

Welding type:

-

HF ERW

-

Speed:

-

30-120m/min

-

Model:

-

Cr12Mov/SKD-11/D2

-

Useful:

-

Produce Galvanized Steel Tubes

-

After Warranty Service:

-

Online support

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Pipe diameter:

-

25.4-76.2mm

Quick Details

-

Pipe Material:

-

Carbon steel

-

Marketing Type:

-

New Product 2021

-

Production Capacity:

-

100m/min

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

380V/50HZ

-

Power:

-

depends on specifications

-

Weight:

-

20000 kg

-

Raw material:

-

Low-carbon Steel

-

Pipe shape:

-

Round Square Rectangle Pipe

-

Color:

-

Customer's Requirement

-

Welding type:

-

HF ERW

-

Speed:

-

30-120m/min

-

Model:

-

Cr12Mov/SKD-11/D2

-

Useful:

-

Produce Galvanized Steel Tubes

-

After Warranty Service:

-

Online support

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Pipe diameter:

-

25.4-76.2mm

Product Description

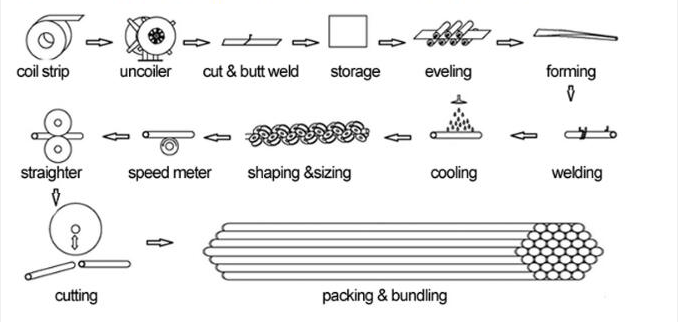

I.Brief introduction

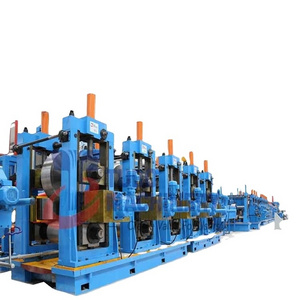

ERW127 high frequency longitudinal welded pipe production line / pipe making machine / tube mill is designed to produce welded pipes of 48 mm-127 mm in OD and 1.5 mm-4.0 mm in wall thickness, as well as corresponding square and rectangular pipe.

ERW127 high frequency longitudinal welded pipe production line / pipe making machine / tube mill is designed to produce welded pipes of 48 mm-127 mm in OD and 1.5 mm-4.0 mm in wall thickness, as well as corresponding square and rectangular pipe.

Equipment advantages:

√ China's largest straight seam welded pipe production line

√ Apply to high strength steel and big thickness

√ Raw material can be steel coil and single plate

√ ZTF forming process save roller up to 60%

√ With direct square forming technology, one set of roller can produce all pipe sizes

√ Electric control and automatic adjustment, high precision,high roller change speed

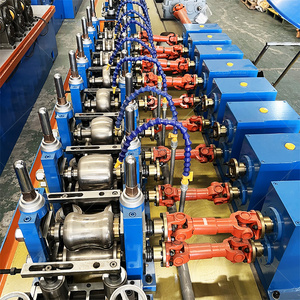

III. Machine Parts

Step 1: Uncoiler

Function:

support old plate and strip tension for erw pipe mill production line, by the frame, main shaft, increases of drum, brake.

Step 2: Shearing butt welding

2 Types:

Automatic & Manual

Function:

Shear the end of each strip coil, then welding them together, so that pipe making welding machine line

can be continue production.

Step 3: Strip Accumulator

Function:

storage strip to keep continue production.

2 Types:

Horizontal/ Vertical

Advantage: Horizontal type can be larger storage. Vertical type is much cheap and small space occupied.

Step 4: Forming Section.

Function:

forming the tube from strip

Advantage:

>Advanced forming technical

>One-stage molding platform

>Reliable quality gearbox

>Siemens Beide motor

Step 5: High Frequency Welding

Function:

Welding the pipe , different thickness & diameter, the power of the HF welding machine welder

Our advantage: We choose the China best welder.

Step 6: Sizing Section

Function:

sizing the tube to precise size

Advantage

:

>Advanced sizing technical

>0ne-stage molding platform

>Reliable quality gear box and Siemens Beide motor

>High precision, low error of the pipe size

Step 7: Flying saw / Cold Saw

Function:

cutting the tube mill line tube to right length.

Fly saw:

easy to operation, low investment.

Cold saw: no noise, no burr cutting precision and cross section.

Specification

|

Model

|

Specification(mm)

|

|

Thickness (mm)

|

Mill Installed Capacity(kw)

|

Line Area(m) - programmable

|

Working Speed (M/min.)

|

|

|

|

Circular

|

Rectangular & Square

|

|

|

|

|

|

|

ERW20

|

Ф8-Ф20

|

10mm×10mm -15mm×15mm

|

0.5-1.5

|

50KW

|

40m*3.8m

|

100

|

|

|

ERW32

|

Ф10-Ф32

|

10mm×10mm -25mm×25mm

|

0.3-2.0

|

50KW

|

45m*4m

|

100

|

|

|

ERW50

|

Ф20-Ф50

|

15mm×15mm – 40mm×40mm

|

0.8-3.0

|

65KW

|

50m*4m

|

100

|

|

|

ERW76

|

Ф32-Ф76

|

25mm×25mm – 60mm×60mm

|

1.2-4.0

|

120KW

|

70m*5m

|

100

|

|

|

ERW89

|

Ф42-Ф89

|

25mm×25mm – 70mm×70mm

|

1.5-4.5

|

150KW

|

72m*5.5m

|

70

|

|

Recommend Products

Company Profie

Zhongtai Group

is

established in 2000

, locates in Shiiazhuang. We are an

IS09001 certified

pipe making machine and cold rolled section steel forming machine manufacturer, reputed enterprise in China's pipe making industry with the largest production capacity,

the most advanced technology and strongest competitiveness

,

one of the executive directors of China Cold-formed Steel Structure Association and one of China's top ten pipe making machinery brands

.

There are three subsidiary companies respectively carry out technology devel-opment, production processing and mould manufacturing.

Plant area 67000 m,with machining, heat treatment and assembly plants.

FAQ

Q:Are you manufacturer?

A:Yes,we are manufacturer. We have 4 factories ( machining, assembling, heat treatment,and mould factory)And we have our own R&D department. Welcome to visit us.

Q:What kind o f payment term you can do?

A: We can accept T/T and L/C.

Q:What info you need before you make the proposal?

A:The pipe diameter , thickness range , usage, raw material steel grade, coil weight and automatic degree.

Q: What should I do if I just start a new business?

A:Contact us immediately ,we provide free consultant for pre-sales service .Also we can help you to solve the raw material (steel coil) purchase,worker training,international market price.

Q:How do you do QA?

A:We have special team to do strict QA,this is one of our strengths:

(1)Every gear box will be tested for 8 hours with oil inside to guarantee there is no leak.

A:Yes,we are manufacturer. We have 4 factories ( machining, assembling, heat treatment,and mould factory)And we have our own R&D department. Welcome to visit us.

Q:What kind o f payment term you can do?

A: We can accept T/T and L/C.

Q:What info you need before you make the proposal?

A:The pipe diameter , thickness range , usage, raw material steel grade, coil weight and automatic degree.

Q: What should I do if I just start a new business?

A:Contact us immediately ,we provide free consultant for pre-sales service .Also we can help you to solve the raw material (steel coil) purchase,worker training,international market price.

Q:How do you do QA?

A:We have special team to do strict QA,this is one of our strengths:

(1)Every gear box will be tested for 8 hours with oil inside to guarantee there is no leak.

(2)Every shaft will be inspected for the centering jumpiness.

(3)Every roller will be checked to make sure its in the range of tolerance critical parts will be inspected for all dimensions.

Q:Why I should choose you,what are the differences between you and other Chinese suppliers?

A:We are concentrate on this industry for more than 20 years,and especially in pipe making machines. Our pipe making machine line directly export to Russia,Vietnam,lndia,Indonesia,and many other countries in Asia, Africa, middle east and South America.

(3)Every roller will be checked to make sure its in the range of tolerance critical parts will be inspected for all dimensions.

Q:Why I should choose you,what are the differences between you and other Chinese suppliers?

A:We are concentrate on this industry for more than 20 years,and especially in pipe making machines. Our pipe making machine line directly export to Russia,Vietnam,lndia,Indonesia,and many other countries in Asia, Africa, middle east and South America.

Hot Searches