The guarantee period of quality shall be 3 years counting from the date on which the commodity arrives at the port of destination.

Except the damage is artificial, we are responsible for offering the fittings free of charge during the guarantee period, but you

need to send the damaged fittings to us by courier with your charge before we send back the alternative fittings to you. Out of

the guaranteed period, should the parts required to be repaired or replaced, if any, the parts will be charged.

- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1500*3000mm

-

Cutting Thickness:

-

0-15mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HITEC

-

Weight (KG):

-

8000 KG

-

Product Name:

-

1kw laser cutting machine

-

Laser Power:

-

High density knives exchange work table

-

Reducer:

-

French MOTOVARIO

-

Rack:

-

Taiwan YYC rack

-

Water chiller:

-

Tongfei water chiller 6200

-

Packing:

-

One 40GP container+One 20 GP container

-

N.W(kg):

-

7500KG

-

Repeat positioning accuracy:

-

±0.02mm

-

Dimension:

-

8.15*2.83*2.12M

-

Max. acceleration:

-

1.5G

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

120m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1500*3000mm

-

Cutting Thickness:

-

0-15mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HITEC

-

Weight (KG):

-

8000 KG

-

Product Name:

-

1kw laser cutting machine

-

Laser Power:

-

High density knives exchange work table

-

Reducer:

-

French MOTOVARIO

-

Rack:

-

Taiwan YYC rack

-

Water chiller:

-

Tongfei water chiller 6200

-

Packing:

-

One 40GP container+One 20 GP container

-

N.W(kg):

-

7500KG

-

Repeat positioning accuracy:

-

±0.02mm

-

Dimension:

-

8.15*2.83*2.12M

-

Max. acceleration:

-

1.5G

Product Description

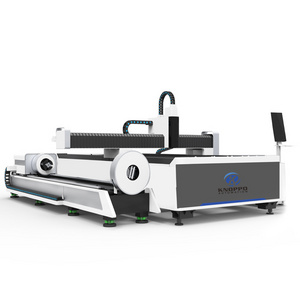

Metal Sheet Fiber Laser Cutter design advantages:

Fully enclosed design;

The observation window adopts European CE standard protective glass;

Cutting produces internal dust filtration treatment, up to standard discharge, no pollution;

The machine weighs 7.5 tons.

Metal Sheet Fiber Laser Cutter Exchange table advantages:

Adopt upper and lower high and low exchange stations;

The inverter controls the exchange motor;

The fastest 15S machine tool exchange is completed.

Metal Sheet Fiber Laser Cutter Segmented rectangular tube welding bed advantage

The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by a plurality of rectangular tubes.

The inside of the tube is provided with reinforcing ribs to increase the strength and tensile strength of the bed, increase

the tensile strength and stability of the guide surface, and effectively avoid deformation of the bed.

the tensile strength and stability of the guide surface, and effectively avoid deformation of the bed.

High strength, stability, tensile strength, guarantee no deformation after 20 years of use;

The rectangular tube has a wall thickness of 10 mm and the entire body weighs 4,500 kg.

Metal Sheet Fiber Laser Cutter User-friendly design:

No need to manually adjust the focus, the software automatically adjusts the focusing mirror to control the height of the upper and lower, so as to realize the automatic perforation cutting of different thickness plates.

The software memorizes the focal length of different plates, and the operation is simpler, which is ten times the artificial speed.

Large adjustment range: +10~——10, precision 0.01mm, suitable for different types of plates from 0~20mm.

Long life: collimating lens focusing lens double water cooling, reducing cutting head temperature and improving cutting head life.

Metal Sheet Fiber Laser Cutter Industry application

The HTF3015GA fiber laser cutting machine can be equipped with a maximum of 8000W laser power, so it is an ideal choice when cutting some thicker plates. For example, in the manufacture of large-scale mechanical equipment such as agricultural machinery, textile machinery, food machinery, and construction machinery, high-power fiber laser cutting machines are usually used for processing.

|

Description

|

Parameter

|

|

Machine Model:

|

HTF-3015GA

|

|

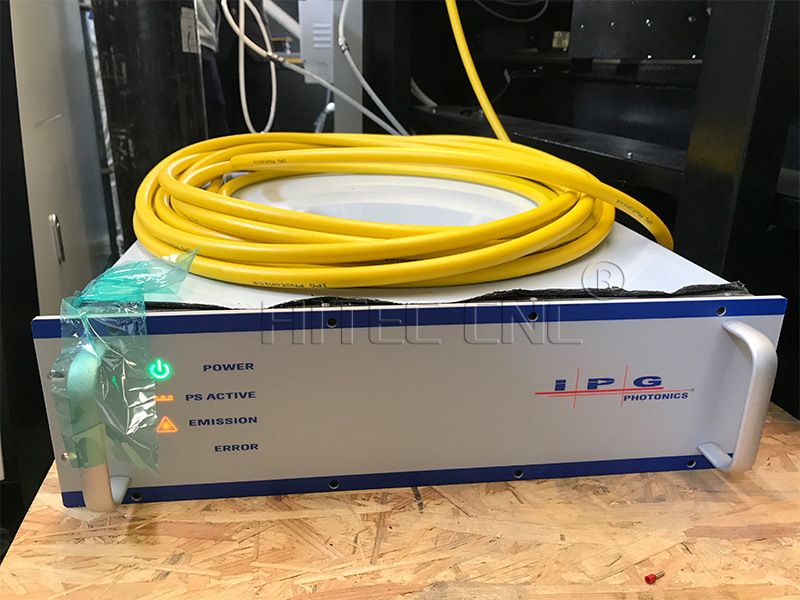

Laser type :

|

IPG Fiber Laser Source

|

|

Laser power :

|

1000w

|

|

Weight

|

8000KG

|

|

Working area

|

1500x3000mm

|

|

Repeated positioning accuracy :

|

±0.02mm

|

|

Max. Acceleration:

|

1.5G

|

|

Max.Running Speed:

|

120m/min

|

|

Transmission :

|

Double driver rack gear

|

|

Power consumption :

|

<10KW

|

|

Specified voltage and frequency :

|

380V 50Hz/60Hz/60A

|

Specification

Metal Sheet Fiber Laser Cutter Raytools laser head

Advantages:

--High Precision: without manual, zero fault.

--High Effectiveness: Without manual,Save time

--High Safety: Anti-collision design, height adjustment

--High sensitivity

Metal Sheet Fiber Laser Cutter Laser generator

Raycus 1 Kw Laser Source Advantage:

100,000 hours life time More stable and cost-efficient Free maintenance

The good brand in the world, quality has assurance.

Metal Sheet Fiber Laser Cutter CYPCUT control system

Auto edge seeking function and flying cutting function, Intelligent typesetting etc. Supported Format: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT,NC,GBX etc

CYPCUT control system

Auto edge seeking function and flying cutting function, Intelligent typesetting etc. Supported Format: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT,NC,GBX etc

The Beam of Metal Sheet Fiber Laser Cutter

Type: Aviation aluminum Beam Structure:Manufactured with aerospace standards And formed by 4300 tons Press extrusion molding.

After aging treatment, its hardness can reach 6061 T6. Advantages:Good toughness,light weight, stronger corrosion

resistance,anti-oxidation,low density to increase the moving speed of laser head.

After aging treatment, its hardness can reach 6061 T6. Advantages:Good toughness,light weight, stronger corrosion

resistance,anti-oxidation,low density to increase the moving speed of laser head.

Comparison: --Steel Gantry: 280kg;

--Cast aluminum Gantry: 180kg;

--Aviation aluminum Gantry: 138kg.

With alight weight, it will greatly increase the processing speed.

Metal Sheet Fiber Laser Cutter With a fully enclosed design

Safety and No Pollution;

The observation window adopts an European CE Standard laser protective glass;

The smoke produced by cutting can be filtrated inside, it's non-polluting environmentally friendly;

Title goes here.

It adopts an up and down exchange platform;

The converter is responsible for controlling the exchanging motor

The machine is able to finish the platform exchanging within 15s

Japan YASKAWA servo motors and drivers

--X axis: one set 850W Japanese YASKAWA servo motor and driver. --Y axis: one set 1800W Japanese YASKAWA servo motor and driver.

--Z axis: one set 400W Japan YASKAWA servo motor and driver.

--Z axis: one set 400W Japan YASKAWA servo motor and driver.

Metal Sheet Fiber Laser Cutter Warranty card and parts

The warranty period is three years from the day of shipment from the factory. If there is any damage, the warranty card can be repaired and replaced for free.

Metal Sheet Fiber Laser Cutter Wearing parts

Nozzlex20pcs/ Protection lensx18pca/Ceramic ringx2for free

Samples

Cutting advantage of Metal Sheet Fiber Laser Cutter

1. High cutting precision: fiber laser cutting machine positioning accuracy 0.05mm, repeat positioning accuracy 0.03 mm. 2. fiber laser cutting machine slit narrow: the laser beam is focused into a small spot, so that the focus reaches a very high power density, the material is quickly heated to the degree of gasification, evaporation to form holes. As the beam moves relatively linearly with the material, the holes are continuously formed into slits having a narrow width, and the slit width is generally 0.10-0.20 mm.

3. The cutting surface of the fiber laser cutting machine is smooth: the cutting surface has no burrs, and the surface roughness of the cutting surface is generally controlled within Ra6.5.

4, fiber laser cutting machine speed: cutting speed up to 10m / min maximum positioning speed up to 30m / min faster than wire cutting speed.

5. fiber laser cutting machine cutting quality is good: no contact cutting, cutting edge is affected by heat, there is basically no thermal deformation of the workpiece, completely avoiding the collapse formed when the material is punched and sheared, the slit generally does not require secondary processing.

6, no damage to the workpiece: the fiber laser cutting head will not contact the surface of the material to ensure that the workpiece is not scratched.

7, not affected by the shape of the workpiece: laser processing is flexible, can process any graphics, can cut pipes and other profiles.

8. fiber laser cutting machine can cut a variety of materials: such as plastic, wood, PVC leather, textiles, plexiglass and so on.

9. Saving mold investment: laser processing does not require molds, no mold consumption, no need to repair molds, saving mold time, thus saving processing costs and reducing production costs, especially suitable for processing large products.

10. Material saving: computer programming can be used to cut products of different shapes to maximize the utilization of materials.

11. Improve the speed of sample delivery: After the product drawings are formed, laser processing can be performed immediately, and the new product can be obtained in the shortest time.

12, safety and environmental protection: laser processing waste, low noise, clean, safe, non-polluting, greatly improving the working environment.

Customer feedback

QC And Service

QC

5 face cnc milling machine which process accurancy can be 0.001mm,to improve all the machine hardware precision,from machine bed,gantry parts to tapping.

All the machine parts Assembe by our machine milling and lathe machine,can be guarantee the machine precision and fast delivery time

Certification

CE certification

Service

Technology support

We welcome all our buyers come to visit our factory for directly free training, our professional engineer will support you to study the machine operation.

We will supply machine operation manual, training videos and machine parameters, our engineer will supply online machine installation and training.

The customers’ technicians can keep in touch with our engineer at any time, through wechat/whatsapp/mobile phone or email, our engineer will help to solve your problems as soon as possible.

If customer need, we will send our engineer to the customers’ place to provide install and train the customer to use the

machine,our engineer will stay at customers’ place for 5-7days,customers should pay the round-trip airkets/hotels/food for our engineer.

The main purpose of pre-sales service is to assist customers to do engineering planning and system requirements analysis, so that

our products can meet the needs of users to the greatest extent, and at the same time make the customer's investment play the

largest comprehensive economic benefit.

our products can meet the needs of users to the greatest extent, and at the same time make the customer's investment play the

largest comprehensive economic benefit.

1. Strengthen user communication and exchange on project progress at any time; 2. As far as possible to meet the changes of the

user's reasonable temporary needs;

3. Collaborate friendly with users to deliver qualified products.

user's reasonable temporary needs;

3. Collaborate friendly with users to deliver qualified products.

Guarantee Policy

Related product

Company Profie

Established in the year 2002,An ISO 9001 Firm.We are manufacturer and develop of the high technology machines.Hitec products are used in a wide variety of industries,markets and applications thoughout all over the world.

Hitec is highly committed to offering the most advanced,capable and efficient manufacturing technology backed by unsurpassed service and support. We offer cnc wood router,cnc laser,cnc plasma,cnc parts.

FAQ

Q1: I need a fiber laser cutting machine, can you give me some suggestions?

Sure, please send us inquiry and tell us your processing materials,size and thickness, we will recommend you suitable model.

Q2: which kind of materials can be processed on this machine?

It can process most of metal

Q3: Are you a factory or trading company?

We are the manufacturer and we have over ten years factory experience .And we welcome you to visit us.

Q4: How long is the delivery time for this Professional manufacturer for fiber laser cutting machine?

For standard machines, it would be 30 days; For non-standard machines and customized machines according to client s specific requirements, it would be 30 to 35 days.

Q5: How should I pay for my order ?

You can do 30% prepayment at first, then we will start to make production. After finish production,shipping,then you can pay that 70% balance.

Sure, please send us inquiry and tell us your processing materials,size and thickness, we will recommend you suitable model.

Q2: which kind of materials can be processed on this machine?

It can process most of metal

Q3: Are you a factory or trading company?

We are the manufacturer and we have over ten years factory experience .And we welcome you to visit us.

Q4: How long is the delivery time for this Professional manufacturer for fiber laser cutting machine?

For standard machines, it would be 30 days; For non-standard machines and customized machines according to client s specific requirements, it would be 30 to 35 days.

Q5: How should I pay for my order ?

You can do 30% prepayment at first, then we will start to make production. After finish production,shipping,then you can pay that 70% balance.

Hot Searches