- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

180*116*229cm

-

Weight:

-

630 KG

-

Product Model:

-

FFE-20L Falling Film Evaporator

-

Evaporation Rate (L/H):

-

20

-

Heating Area (㎡):

-

1

-

Condensing Area (㎡):

-

2+0.5

-

Vacuum Degree (Mpa):

-

-0.095

-

Heating Power (KW):

-

15

-

Feed Pump (KW):

-

0.75

-

Water Circulating Vacuum Pump (KW):

-

0.75

-

Power Supply:

-

220V/60Hz

-

Marketing Type:

-

Hot Product 2022

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Lanphan

-

Voltage:

-

220V/60HZ

-

Dimension(L*W*H):

-

180*116*229cm

-

Weight:

-

630 KG

-

Product Model:

-

FFE-20L Falling Film Evaporator

-

Evaporation Rate (L/H):

-

20

-

Heating Area (㎡):

-

1

-

Condensing Area (㎡):

-

2+0.5

-

Vacuum Degree (Mpa):

-

-0.095

-

Heating Power (KW):

-

15

-

Feed Pump (KW):

-

0.75

-

Water Circulating Vacuum Pump (KW):

-

0.75

-

Power Supply:

-

220V/60Hz

-

Marketing Type:

-

Hot Product 2022

A single-effect falling film evaporator can be used to evaporate extract liquid under reduced pressure or vacuum condition so that ethanol and liquid material can be separated, condensed and recycled.

| Product Model | FFE-20 |

| Evaporation Rate (L/H) | 20 |

| Heating Area (spuare meter) | 1 |

| Condensing Area (square meter) | 2+0.5 |

| Vacuum Degree (Mpa) | -0.095 |

| Heating Power (KW) | 15 |

| Feed Pump (KW) | 0.75 |

| Water Circulating Vacuum Pump (KW) | 0.75 |

| Power Supply | 220V/60Hz Three Phase, other can be customized. |

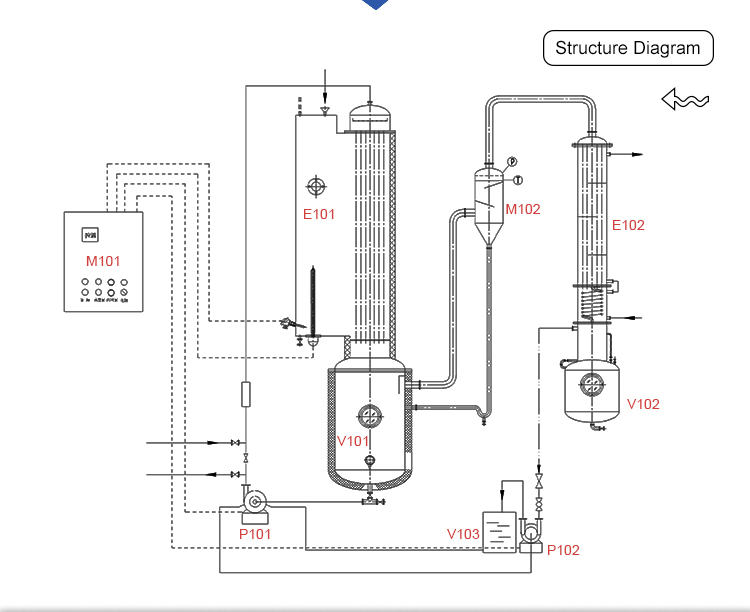

Principle of Falling Film Evaporator:

The liquid material is distributed evenly into each falling film tube by distributors and flows downward along the tube wall in the form of liquid film. The liquid material is evaporated during the process of flowing downward under actions of gravity and secondary steam flow. The liquid material and secondary steam are separated basically after reaching the lower part of falling film tubes and separated completely after reaching the separation chamber.

A single-effect falling film evaporator is widely used in food, dairy, chemical, biological engineering, environmental engineering and deep processing of corn. For example, it is applicable for the evaporation and concentration of aqueous solution, organic solvent solution, fruit and vegetable juice, milk, egg product, vitamin C, collagen, infusion of tea, sodium glutamate and other liquid materials. It is especially suitable for the evaporation and concentration of heat-sensitive materials, because the beneficial elements can be protected to the greatest extent during the heating and evaporation of materials.