- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

4.025

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Voltage:

-

220V/3800V/Customize

-

Rated voltage:

-

380V

-

Quality standard:

-

ISO

-

Name:

-

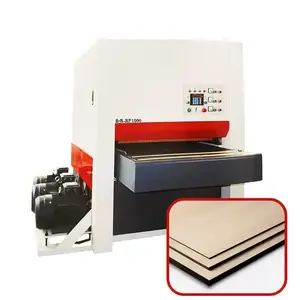

Mini sanding machine wood furniture machinery

-

Drive wheel speed:

-

2870 r/min

-

Workbench size:

-

1180*240*2 mm

-

Belt line speed:

-

18m/sec

-

Workbench stroke:

-

80mm

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

kingrunda

-

Weight (KG):

-

300 KG

-

Power (kW):

-

4.025

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Voltage:

-

220V/3800V/Customize

-

Rated voltage:

-

380V

-

Quality standard:

-

ISO

-

Name:

-

Mini sanding machine wood furniture machinery

-

Drive wheel speed:

-

2870 r/min

-

Workbench size:

-

1180*240*2 mm

-

Belt line speed:

-

18m/sec

-

Workbench stroke:

-

80mm

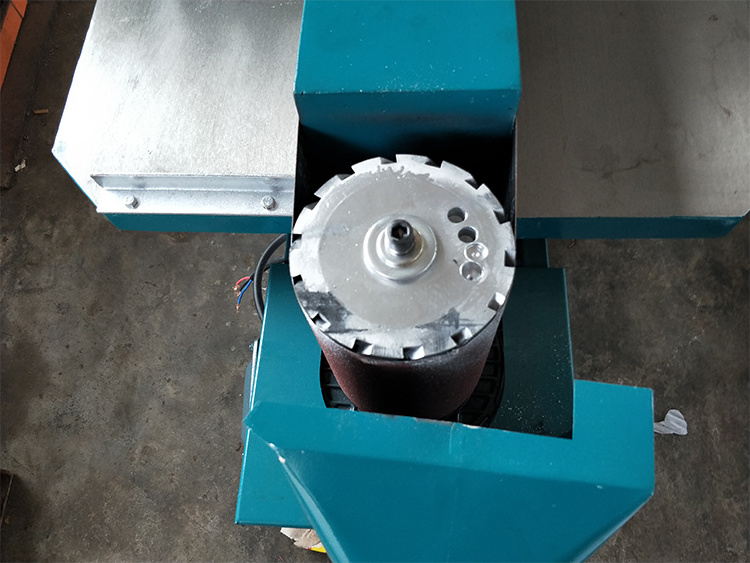

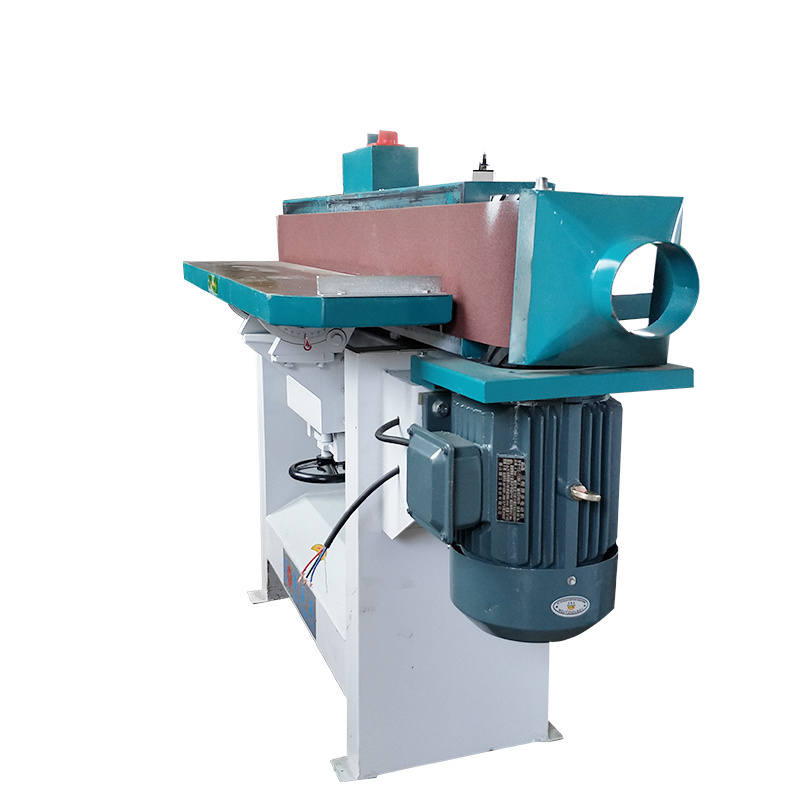

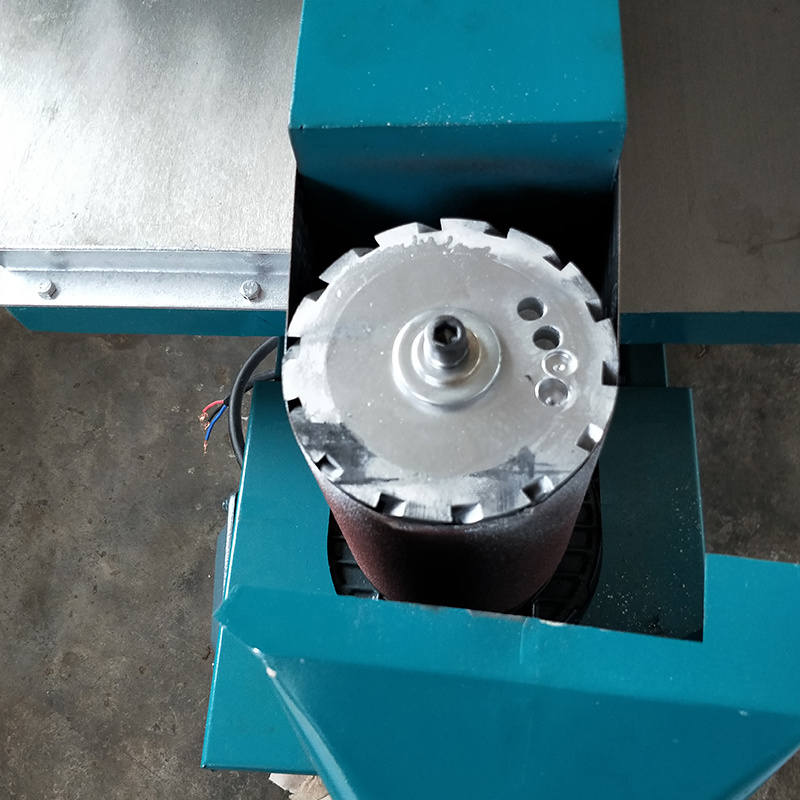

Vertical tilting sander

Model : MM2617

Drive wheel speed : 2870 r/min

Workbench size

:

1180*240*2 mm

Belt line speed

:

18m/sec

Sander use

The sanding machine is a special grinding machine for the wood manufacturing industry by driving the belt with a linear motion to achieve the surface of the workpiece to achieve the required finish. The sander is safe to operate and has low noise. It has a two-head suction hood, which can be used for both vertical vertical polishing and oblique sanding.

Sanding machine use and maintenance

1. When the sander is shipped to the destination, she should be padded. Connect the 380V power supply and grounding wire, install the belt dust cover, and run for five minutes without load. Make sure the belt is running in the right direction and there is no fault before it can be used.

2. Before use, adjust the height and inclination of the work according to the needs of the work.

3. Adjustment of the belt. Loosen the locking handle and turn the belt to tighten the handwheel. When the belt is tight, tighten the locking handle. The belt cannot be adjusted too tightly; otherwise it will affect the service life of the belt and even break the axle. When the sander works for a period of time, the abrasive belt will be elongated, which will affect the quality of the work, and the tightness of the abrasive belt must be adjusted.

4. Adjustment of the belt movement. Rotate the belt to move the adjustment hand wheel. If the handle wheel is rotated upwards, the belt will move downwards; otherwise, the belt will move upwards.

5. When sanding work, be sure to put the polished surface close to the sanding board to avoid the sanding quality.

6. If you find noise during work, stop it immediately and check it.

7. After the work is finished, turn off the power, turn the power combination switch back to zero, and clean the machine.

8. Regularly clean and add lubricant to the lifting and lowering plates of the workbench.

9. The work surface cannot be slammed and stressed, so as not to affect the quality of work.

| Vertical tilting sander | |

| Model | MM2617 |

| Drive wheel speed | 2870 r/min |

| Workbench size | 1180*240*2 mm |

| Belt line speed | 18m/sec |

| Workbench stroke | 80mm |

| Belt size | 3120*170mm |

| Installation power | 4.025kw |